The WCB Explosion-Proof Electric Butterfly Valve is an essential component in modern industrial processes, particularly in environments where flammable gases and liquids are present. These valves play a crucial role in ensuring safety, efficiency, and reliability in fluid control systems. In this article, we will delve into the design, functionality, applications, and advantages of the WCB Explosion-Proof Electric Butterfly Valve.

Design Features

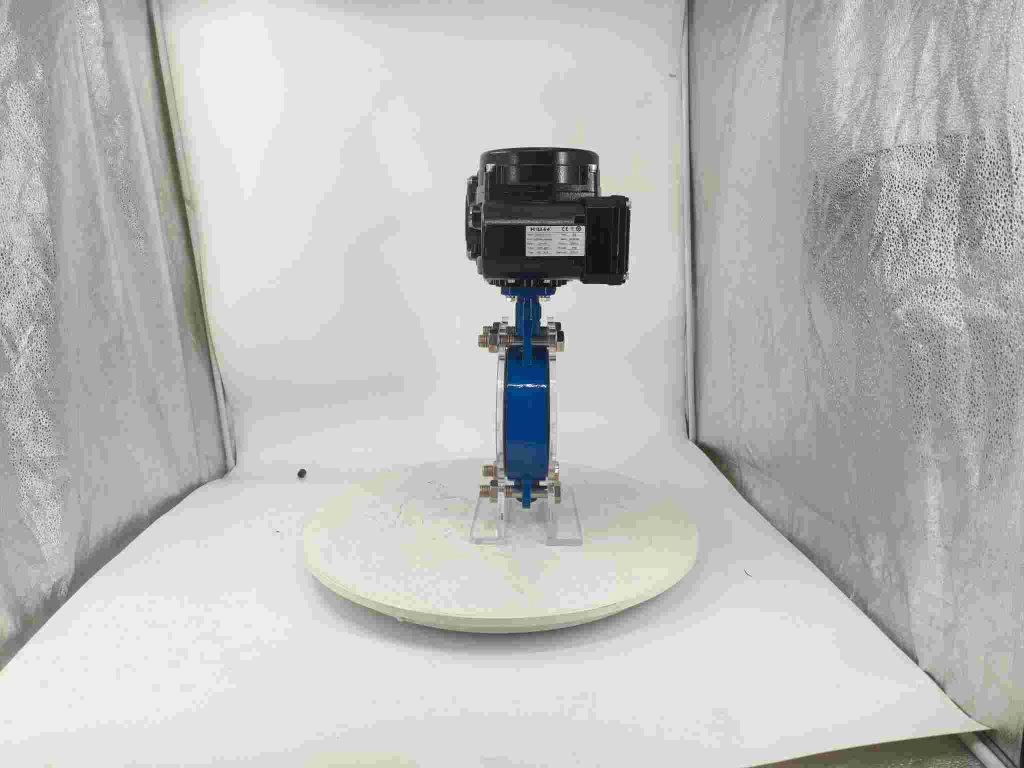

The WCB Explosion-Proof Electric Butterfly Valve is engineered with safety and durability in mind. The term “WCB” refers to the material of the valve, which is made from cast iron, known for its excellent mechanical properties and resistance to corrosion. The explosion-proof feature is vital for operations in hazardous environments, as it prevents the risk of ignition from electrical components. This valve is often fitted with an electric actuator that allows for remote control, providing convenience and precision in fluid regulation. The butterfly valve design itself consists of a disc that rotates around a central axis. When the valve is in the closed position, the disc blocks the flow of fluid. Conversely, when the valve is opened, the disc aligns with the flow direction, allowing for unrestricted passage. This simple yet effective design contributes to the valve’s ability to handle large volumes of fluids with minimal pressure drop.