In the industrial landscape, safety and efficiency are paramount, especially in environments characterized by hazardous materials. One significant product that meets these safety demands is the explosion-proof electric butterfly valve. For businesses requiring tailored solutions, partnering with Original Design Manufacturers (ODM) specializing in explosion-proof electric butterfly valves can be a game changer. This article explores the essence of explosion-proof electric butterfly valve ODM manufacturers, their benefits, and considerations for choosing the right partner.

The Importance of Explosion-proof Electric Butterfly Valves

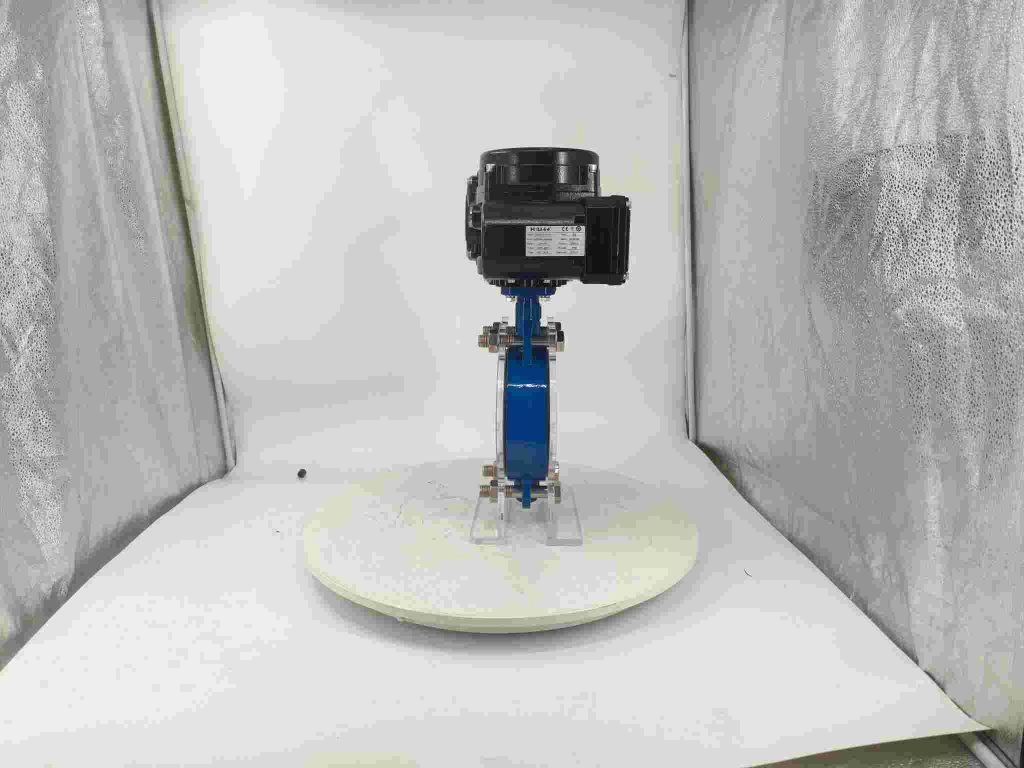

Explosion-proof electric butterfly valves are critical components in sectors such as chemical processing, oil and gas, and waste management, where flammable gases and volatile liquids are prevalent. These valves are engineered to remain operational under potentially explosive conditions, safeguarding personnel and equipment. Their primary function is to regulate the flow of fluids within pipelines and mitigate the risk of leaks or accidents. The design of these valves adheres to stringent international safety standards, such as the ATEX (Atmosphères Explosibles) and IECEx (International Electrotechnical Commission Explosive) certifications. These standards ensure that the valves operate reliably even in the most critical environments.