Metal stamping is a crucial process in various industries, from automotive to electronics, where precision and efficiency are paramount. At the heart of this process lies the metal stamping die, a specialized tool designed to shape and cut metal sheets into desired forms. The role of a metal stamping die manufacturer is vital, as they provide the essential components that enable businesses to produce high-quality metal parts efficiently.

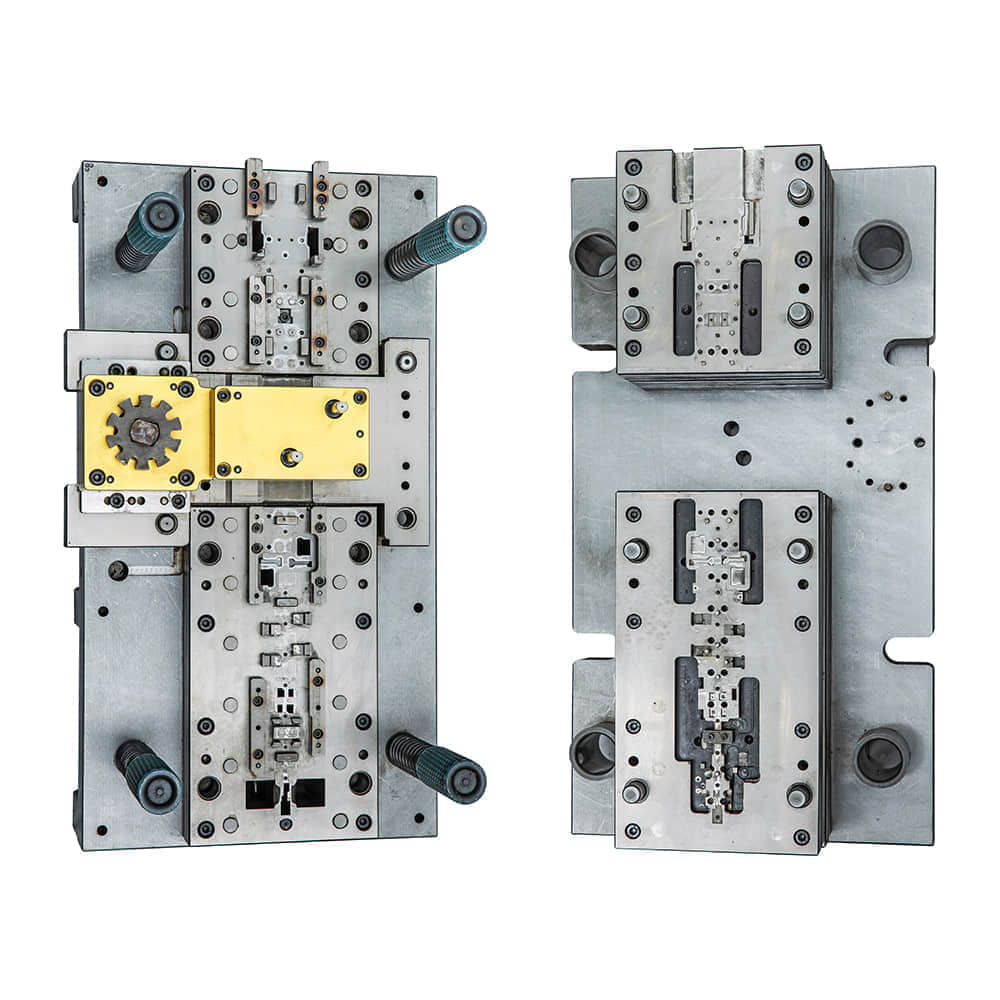

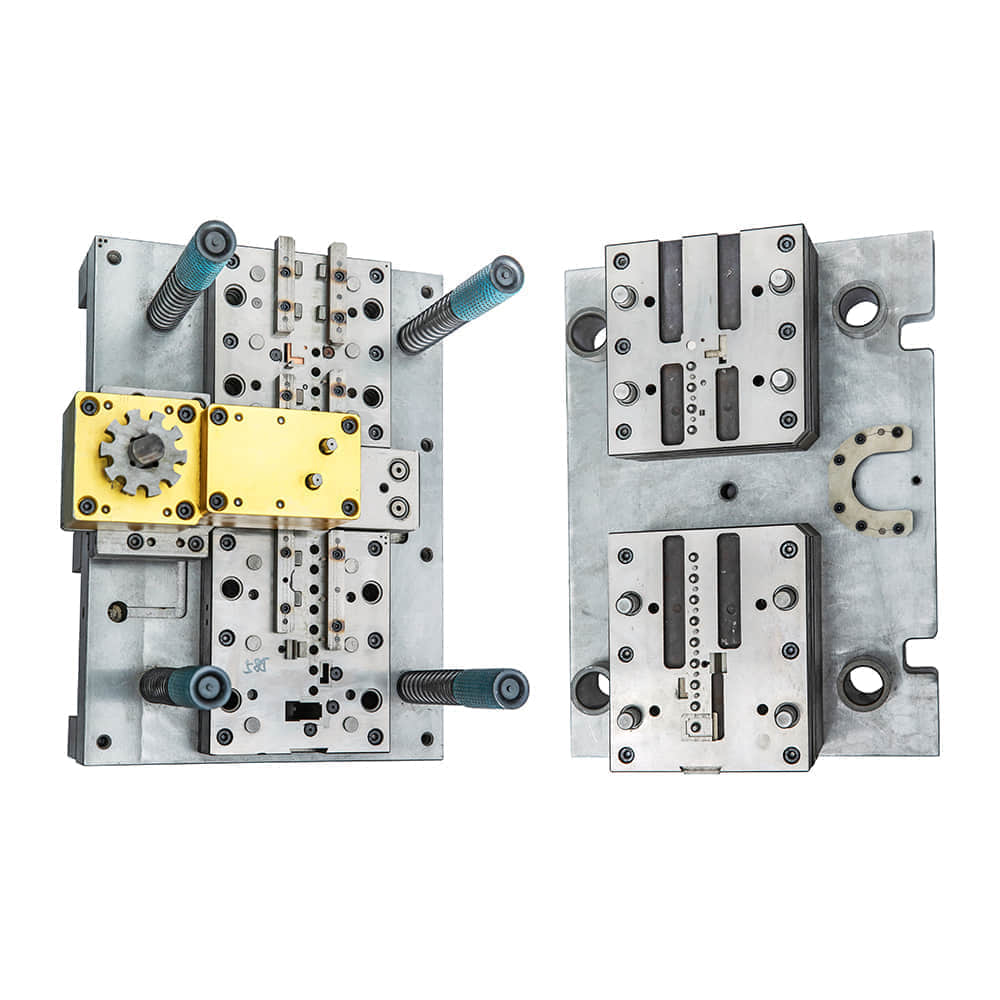

A metal stamping die manufacturer designs and produces dies that are tailored to specific applications. The design phase involves close collaboration with clients to understand their requirements, including material type, thickness, and the complexity of the part. Advanced software is often utilized to create precise designs that can be tested virtually before production begins. This iterative design process helps ensure that the final product meets the necessary specifications and reduces the likelihood of costly errors.

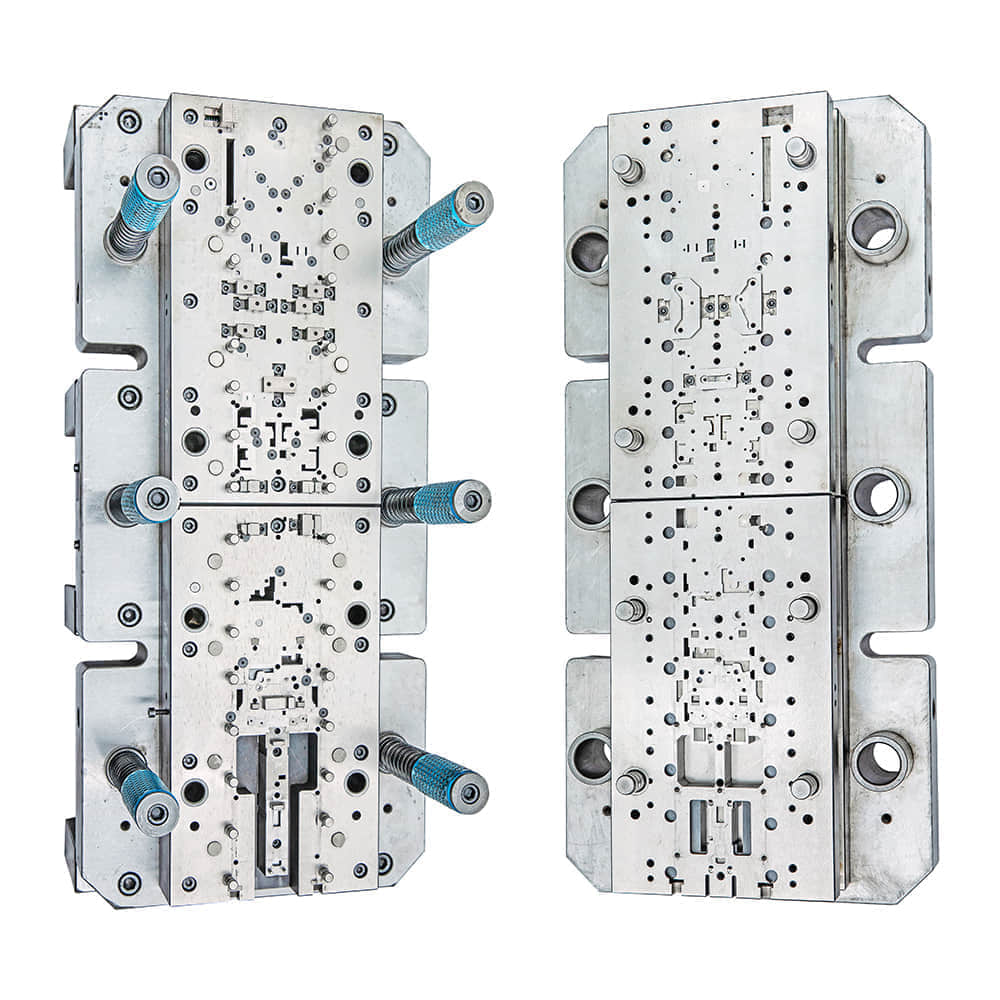

Once the design is finalized, the manufacturing process begins. Metal stamping die manufacturers typically use high-grade materials such as tool steel, which can withstand the pressures involved in the stamping process. The dies are machined using CNC (Computer Numerical Control) technology, which allows for intricate details and high precision. After machining, the dies undergo rigorous testing to ensure they perform flawlessly under production conditions. Quality control is another critical aspect of a metal stamping die manufacturer’s responsibilities. The dies must be tested for durability and performance, ensuring they can produce consistent results over time. Manufacturers often implement strict quality assurance protocols, which may include dimensional inspections, material testing, and functional testing to validate that the dies meet industry standards.