In the world of automation, fluid control is a critical aspect of various industries, ranging from healthcare to manufacturing. One of the essential components in fluid control systems is the solenoid valve. While traditional solenoid valves are widely used, the mini solenoid valve has gained prominence due to its compact size and high functionality. This article explores the features, applications, and advantages of mini solenoid valves, demonstrating how they provide effective and efficient fluid control in constrained spaces.

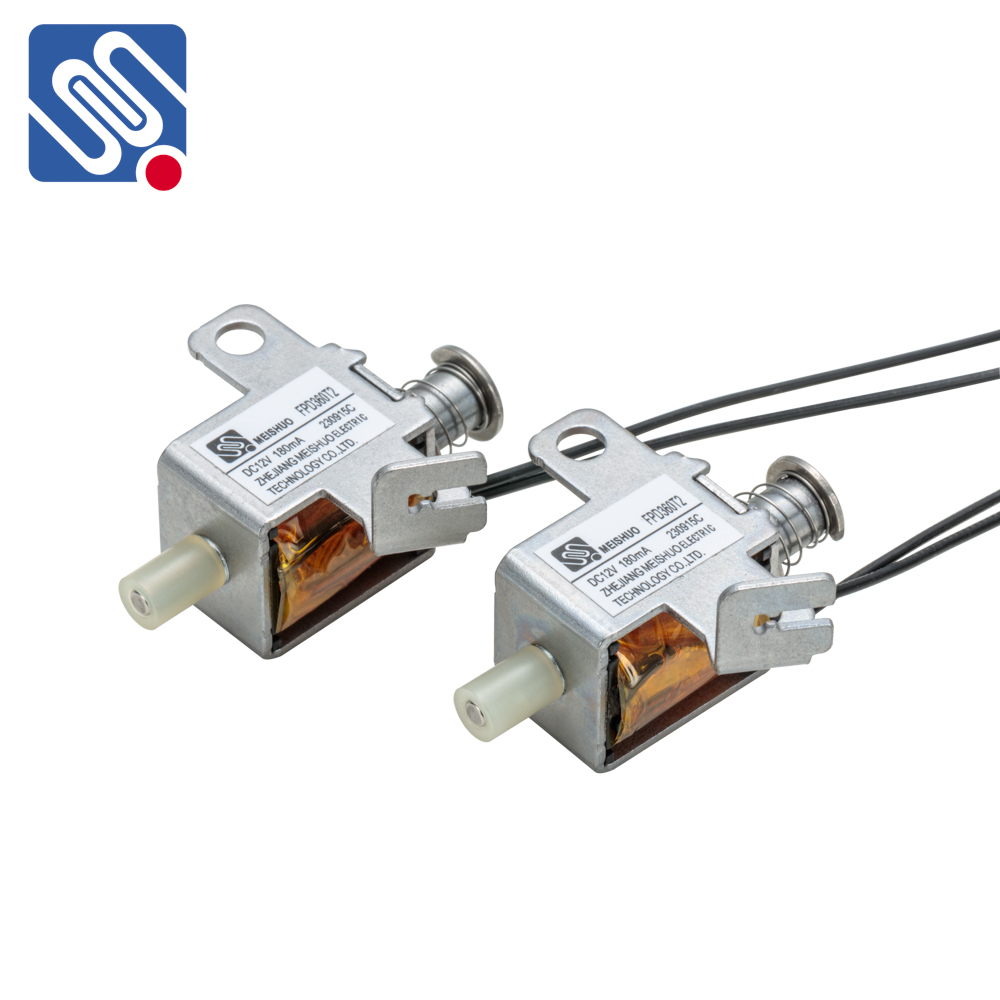

What is a Mini Solenoid Valve? A mini solenoid valve is a small-sized electromagnetic valve that controls the flow of fluids or gases in a system. It operates by using an electromagnetic coil to open or close the valve, allowing or stopping the flow of fluid. These valves are typically used in applications where space is limited but precise fluid control is still necessary. The mini solenoid valve offers the same functionality as larger solenoid valves but in a more compact form, making it suitable for a variety of modern applications. How Does a Mini Solenoid Valve Work? At the core of the mini solenoid valve is the electromagnetic coil. When electrical current passes through the coil, it generates a magnetic field that actuates the valve. The valve’s design typically includes a plunger or diaphragm that moves when the magnetic field is applied. This movement either opens or closes the valve, regulating the flow of fluid or gas.