In various industrial applications, maintaining safety and efficiency is paramount. One of the crucial components that contribute to both these aspects is theExplosion-proof electric butterfly valve. This type of valve not only helps regulate the flow of liquids and gases but also ensures that operations are conducted safely, especially in hazardous environments. This article will explore the features, advantages, and applications of explosion-proof electric butterfly valves, highlighting their importance in modern industrial processes.

What is an Explosion-proof Electric Butterfly Valve?

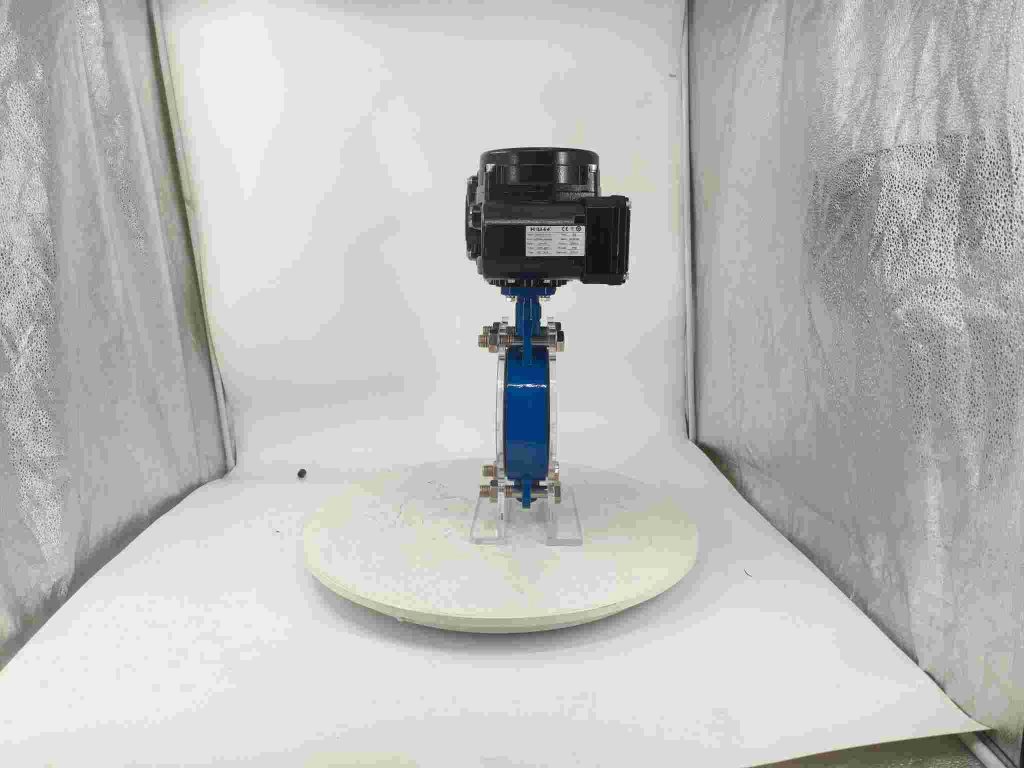

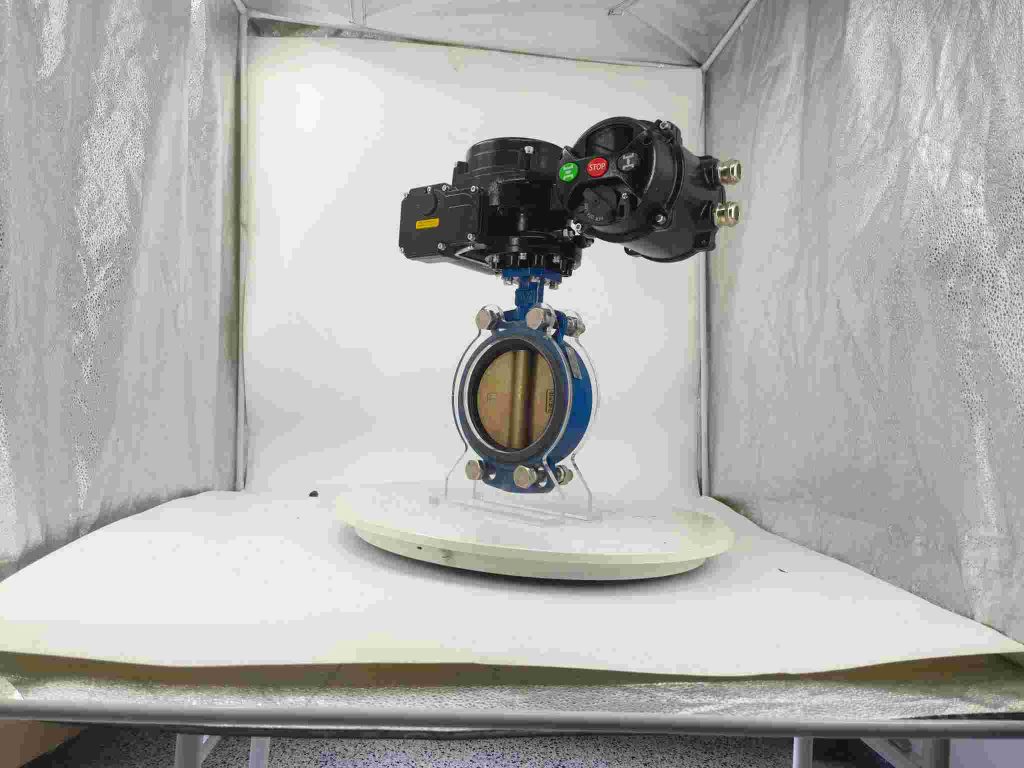

An explosion-proof electric butterfly valve is a type of valve that employs a rotating disc to control the flow of fluids. The term “butterfly” refers to the valve’s disc, which resembles a butterfly’s wings when opened. This valve is powered by an electric actuator, which allows for remote operation and automation. The explosion-proof designation indicates that the valve is designed to operate safely in environments where flammable gases or vapors may be present. These valves are constructed with materials and designs that can withstand harsh conditions, including high pressure and temperature fluctuations. The explosion-proof feature is particularly vital in industries such as oil and gas, chemical manufacturing, and wastewater treatment, where the risk of explosion or fire is significant.