Relay assembly is a crucial component in electrical and mechanical systems, allowing for the efficient control of high-power circuits using low-power signals. The process involves the installation and integration of relays to perform specific control tasks, such as turning devices on and off, protecting circuits, or regulating operations in various machines and systems. In this article, we will explore the fundamental principles behind relay assembly, its key components, and the various applications in which it is used.

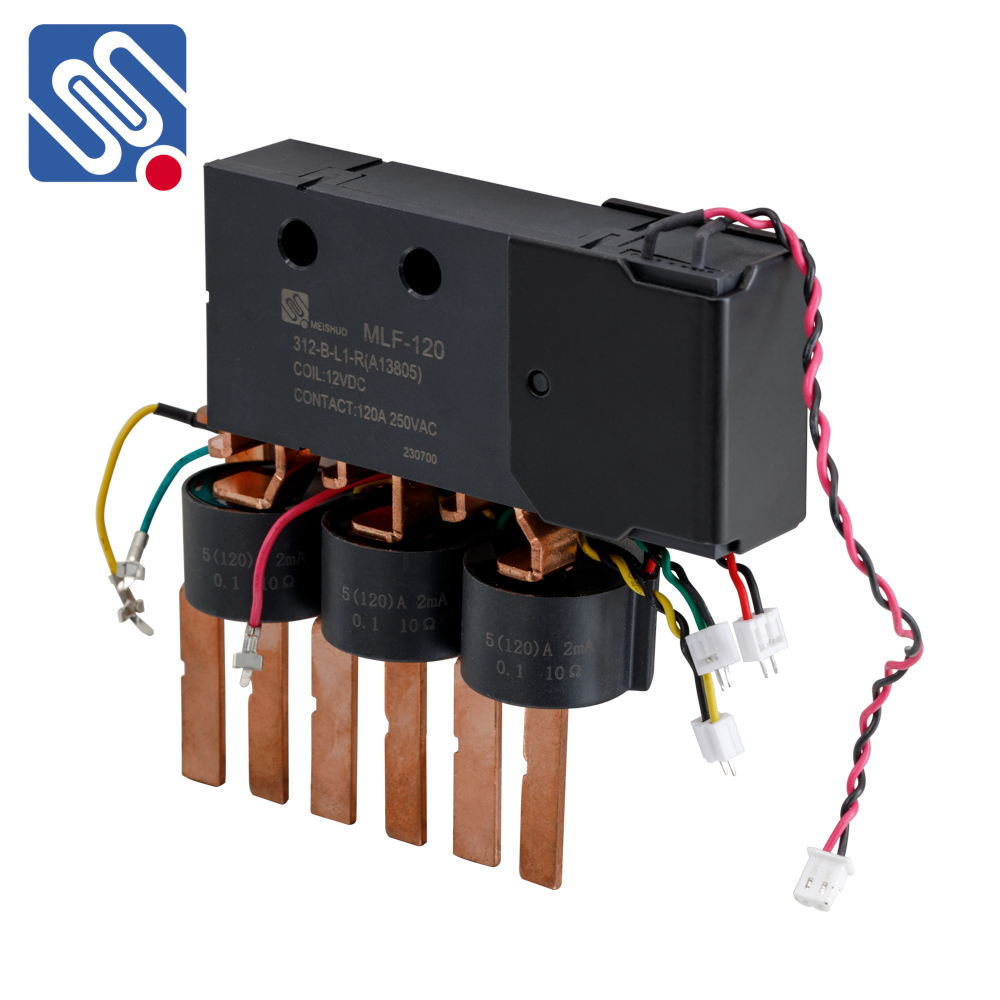

What is Relay Assembly? At its core, relay assembly refers to the process of integrating electrical relays into a system to control the flow of electricity or signals based on predetermined conditions. A relay is an electromagnetic switch that opens or closes a circuit in response to an electrical signal. It operates by energizing a coil, which generates a magnetic field that moves a set of contacts, thus switching the circuit between two states (open or closed). These devices are highly valued for their ability to control a large load using a small input signal. The relay assembly process involves selecting the appropriate relay type, ensuring its proper installation, connecting it to the necessary circuits, and testing the system to ensure it operates as intended. Relay assemblies can vary in complexity depending on the specific requirements of the application, such as the number of contacts, the type of relay used (mechanical, solid-state, etc.), and the operational environment.