Relay assembly is a crucial process in the manufacturing of electronic devices, especially in systems that require reliable and efficient control mechanisms. A relay, in its simplest form, is an electrically operated switch that is used to control the flow of electrical current in a circuit. It has a wide range of applications, from automotive systems to industrial machinery, home appliances, and telecommunication devices. Understanding the basics of relay assembly, its components, and how it works can help in optimizing its design and application for various technological needs.

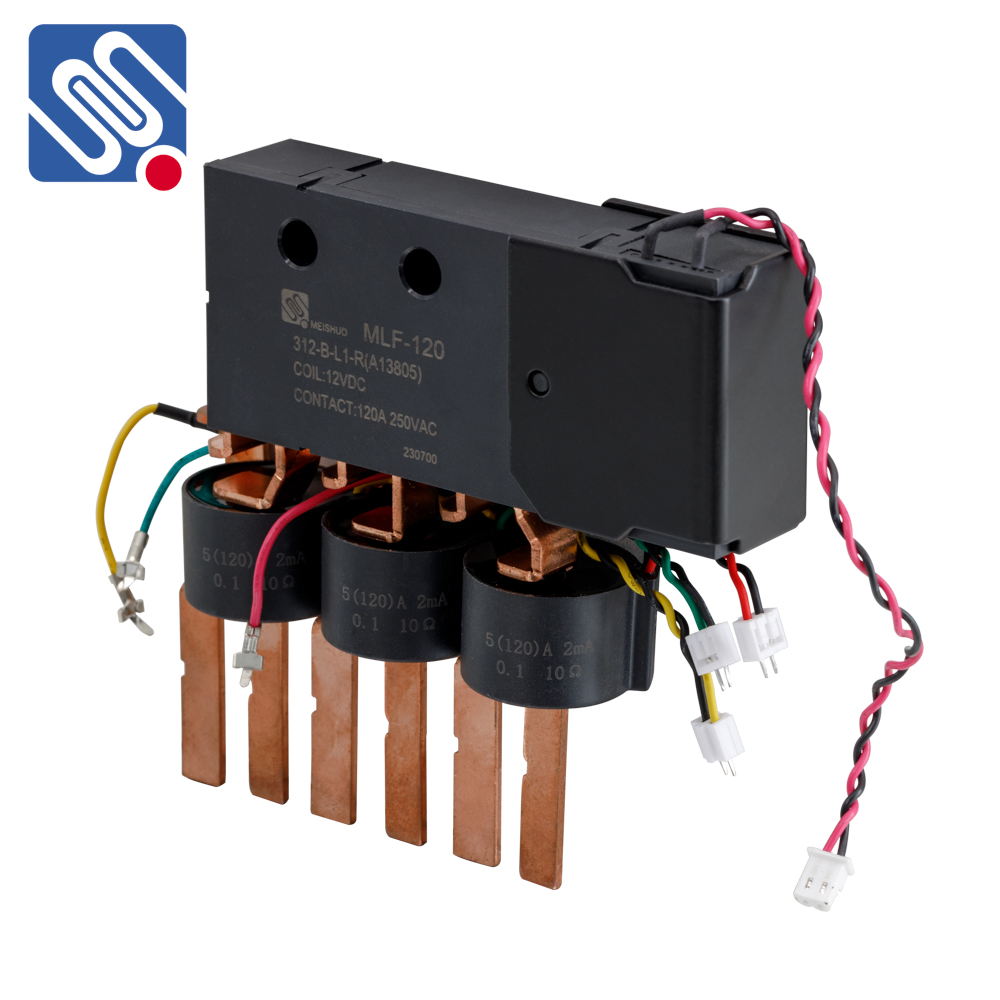

The Basics of Relay Assembly At its core, a relay assembly involves several key components: the coil, the armature, the spring, the contacts, and the frame. The coil, usually made from copper wire, is the primary component that generates the electromagnetic field when a current is passed through it. The armature, which is a movable metal piece, is attracted towards the coil when the electromagnetic field is generated. This movement opens or closes electrical contacts, which in turn controls the flow of electricity through the circuit. The spring plays an essential role in ensuring that the armature returns to its default position when the current to the coil is turned off. The contacts, which are made from durable materials like silver or copper, are the parts that physically make or break the connection between the circuits. The frame houses and supports all these components, providing stability and durability to the relay assembly.