Progressive Die: A Catalyst for Manufacturing Efficiency

In the realm of modern manufacturing, efficiency reigns supreme. Manufacturers continually seek innovative ways to streamline production processes and reduce costs while maintaining or even improving product quality. One such innovation that has played a pivotal role in achieving these goals is the progressive die. In this article, we will delve into the world of progressive dies, exploring their function, benefits, and their impact on the manufacturing industry.

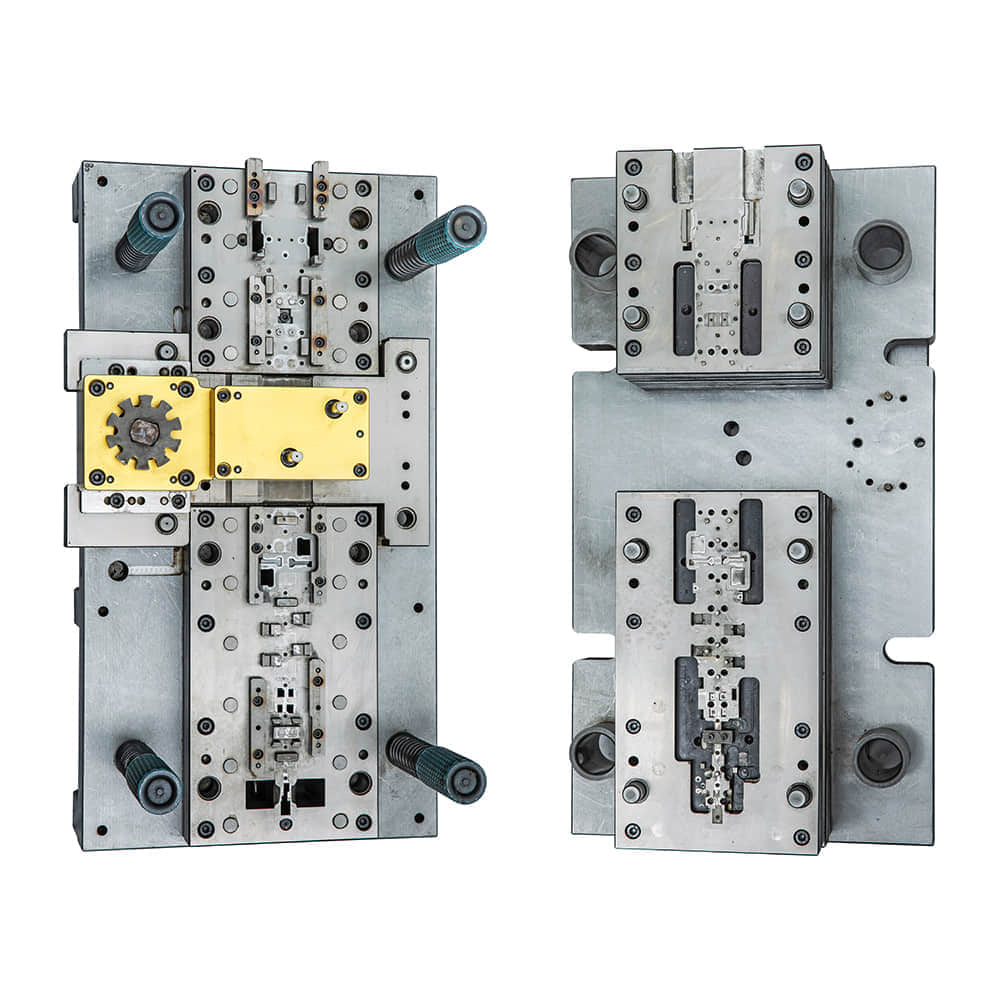

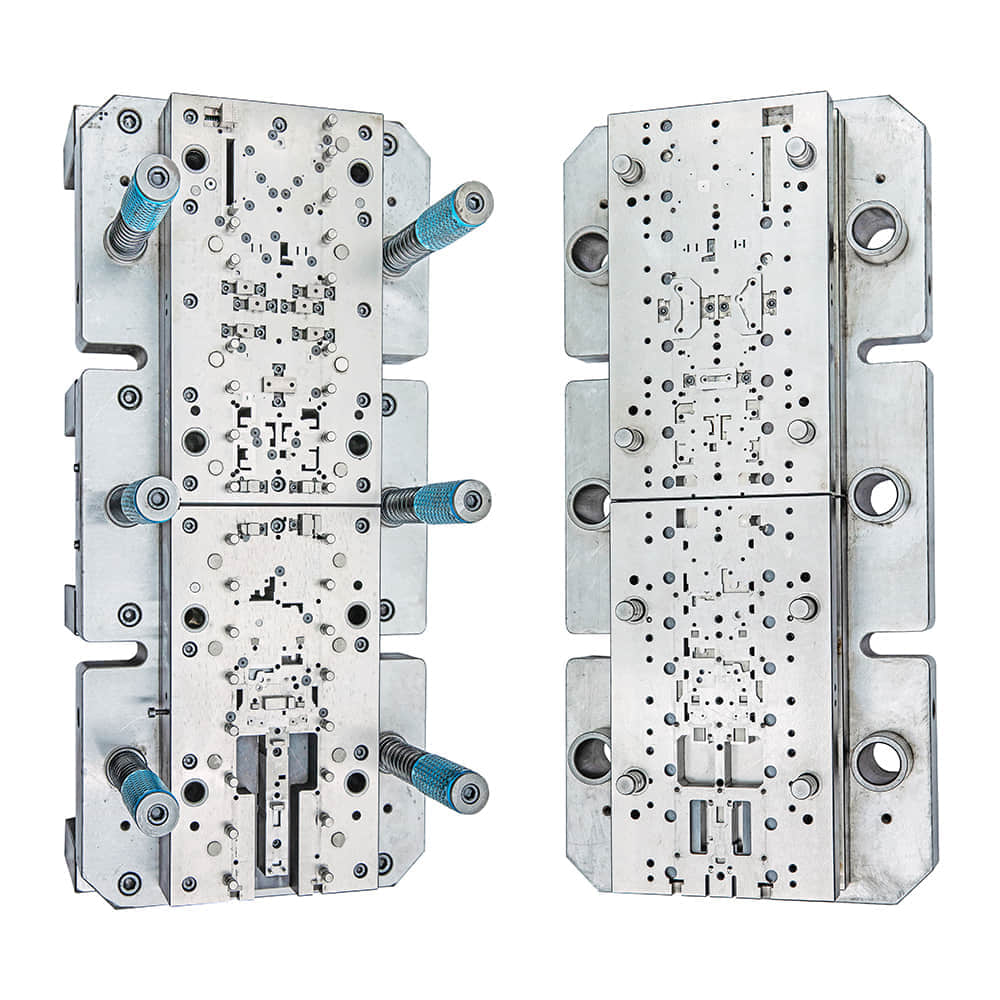

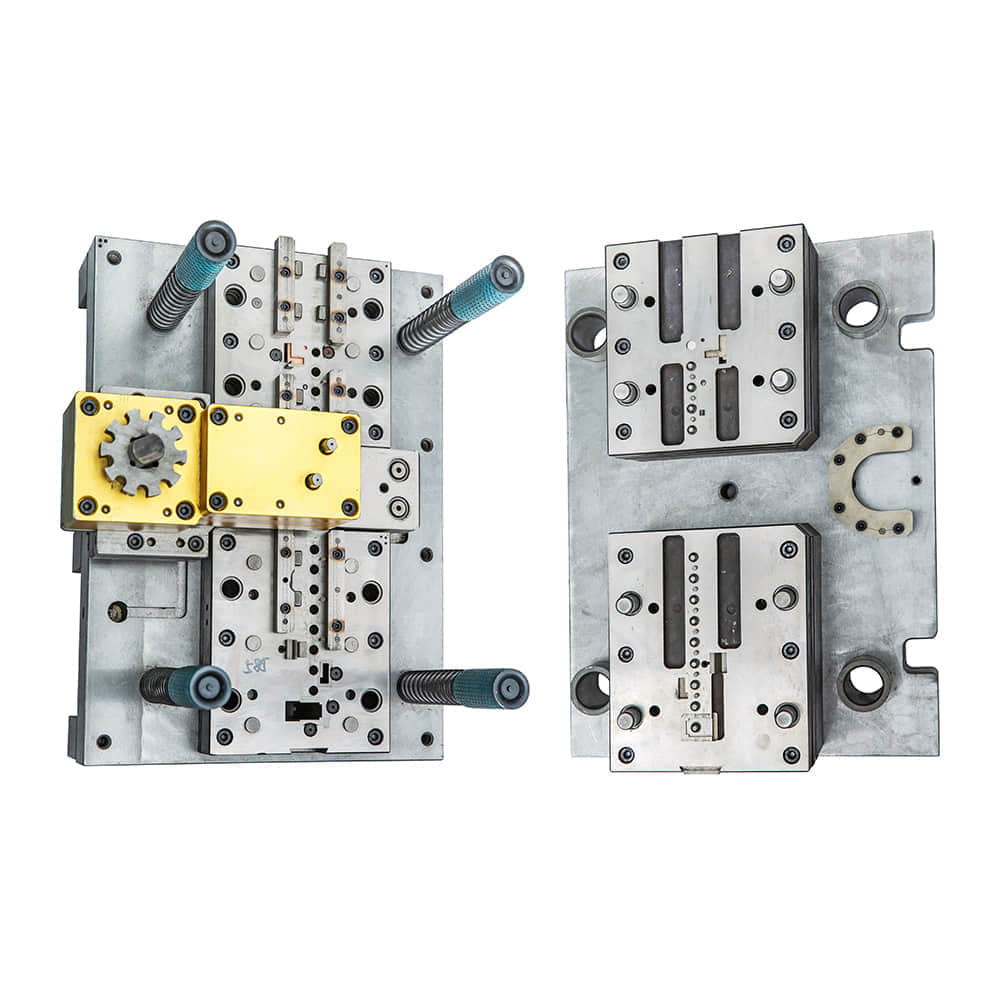

What is a Progressive Die? A progressive die is a specialized tool used in metalworking and stamping operations. Its primary function is to convert flat metal sheets into finished components with speed and precision. Unlike conventional stamping dies, which typically produce one component per operation, progressive dies are capable of performing multiple operations in a single stroke. This unique feature sets them apart as a powerful tool for high-volume manufacturing. How Does a Progressive Die Work? Progressive dies consist of a series of interconnected stations or stages, each equipped with various cutting, bending, and forming tools. These stations are strategically arranged along a linear path within the die. The metal sheet passes through these stations as it moves progressively, with each station performing a specific operation on the sheet. These operations may include blanking, piercing, bending, and even threading. As the metal sheet advances through the die, it undergoes a sequence of transformations, gradually taking shape as the final component. The key to the progressive die’s efficiency lies in its ability to eliminate the need for manual handling and repositioning of the workpiece between operations. This continuous, automated process significantly reduces production cycle times and minimizes the risk of errors. Benefits of Progressive Dies Increased Efficiency: Progressive dies are known for their exceptional speed and efficiency. By performing multiple operations in a single stroke, they greatly reduce production time, making them ideal for high-volume manufacturing. Cost Savings: The automation provided by progressive dies reduces the need for skilled labor and minimizes material waste. This translates into lower production costs, making products more competitive in the market. Consistency and Precision: Progressive dies ensure consistent product quality. The repeatability of each operation, coupled with precise tooling, leads to components with tight tolerances. Versatility: These dies are highly adaptable and can be designed to produce a wide range of components. Tooling can be easily modified to accommodate design changes. Reduced Scrap: With minimal material waste and precise operations, progressive dies help minimize scrap generation, further contributing to cost savings and environmental sustainability. Increased Production Capacity: Manufacturers can ramp up production volumes without significantly increasing the footprint of their facilities, thanks to the compact nature of progressive die setups. Applications of Progressive Dies Progressive dies find applications in various industries, including automotive, electronics, appliances, and aerospace. They are commonly used to manufacture components such as brackets, connectors, clips, and electrical contacts. Additionally, they are invaluable in the production of intricate parts with complex geometries. Challenges and Considerations While progressive dies offer numerous advantages, they are not without their challenges. Designing a progressive die requires a high level of expertise and precision, and any errors in the design can lead to costly production issues. Additionally, maintenance and upkeep are crucial to ensure the die continues to operate efficiently over its lifespan. In conclusion, progressive dies have revolutionized the manufacturing industry by enhancing efficiency, reducing costs, and improving product quality. Their ability to perform multiple operations in a single stroke makes them indispensable in high-volume production environments. As technology continues to advance, it is likely that progressive dies will evolve further, playing an even more significant role in the manufacturing landscape.