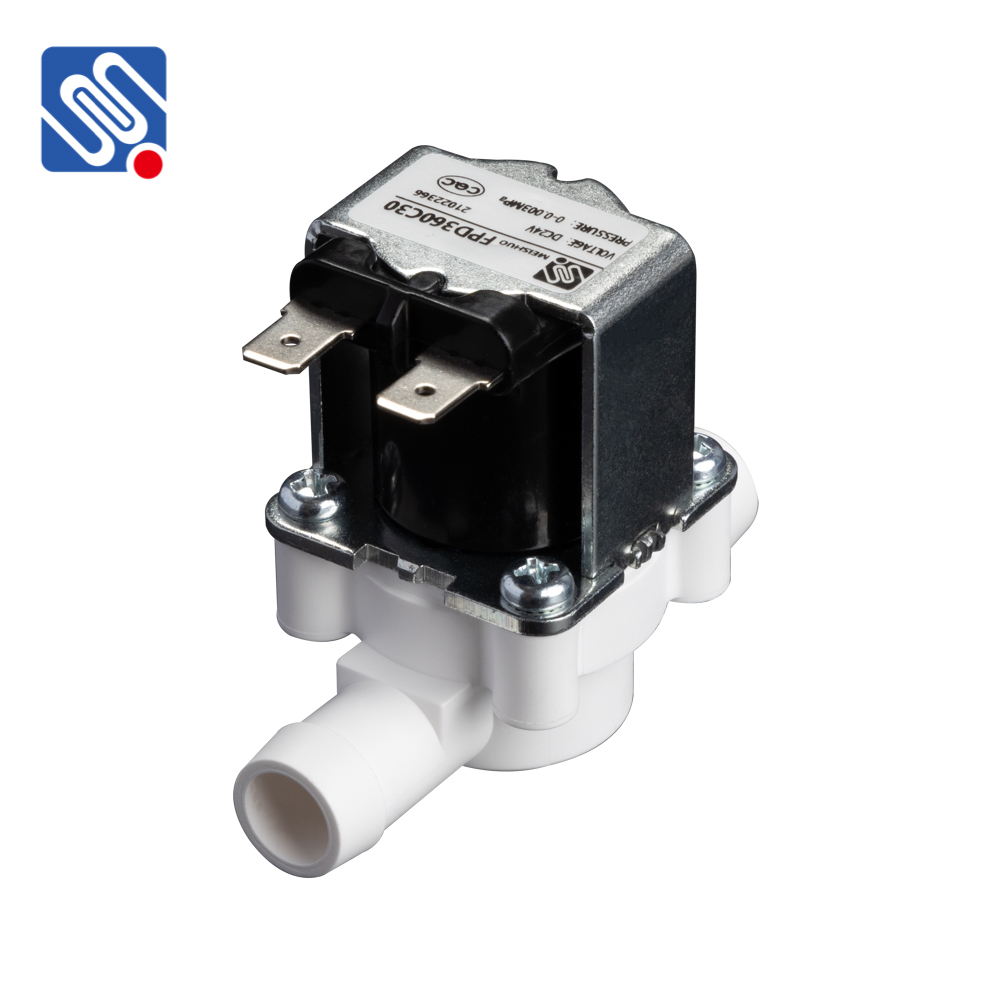

A Low Voltage Solenoid Valve (LVSV) is an essential component in a wide range of industrial and domestic applications, controlling the flow of liquids or gases by means of an electrical signal. These valves are particularly popular for their efficiency, precision, and energy-saving capabilities. Typically powered by low-voltage direct current (DC), such as 12V or 24V, they are used in automated systems where fluid control is necessary. In this article, we will explore the working principle, key features, advantages, and common applications of low-voltage solenoid valves.

Working Principle of Low Voltage Solenoid Valve The fundamental working principle behind a Low Voltage Solenoid Valve involves the use of an electromagnetic coil to control the valve mechanism. When electric current flows through the solenoid coil, it generates a magnetic field that activates a plunger or armature inside the valve. This plunger movement opens or closes the valve, regulating the flow of fluid (liquid or gas) through the pipe. Upon de-energizing the coil, a spring mechanism usually returns the plunger to its initial position, which could either be fully open or closed, depending on the type of valve (normally open or normally closed).