In industrial applications where safety and reliability are paramount, the selection of appropriate valves is crucial. One such critical component is the explosion-proof electric butterfly valve. These valves are designed to prevent the risk of explosion in environments where flammable gases or liquids are present. This article explores the significance of explosion-proof electric butterfly valves and the role of OEM (Original Equipment Manufacturer) manufacturers in providing high-quality products tailored to specific industry needs.

The Importance of Explosion-Proof Electric Butterfly Valves

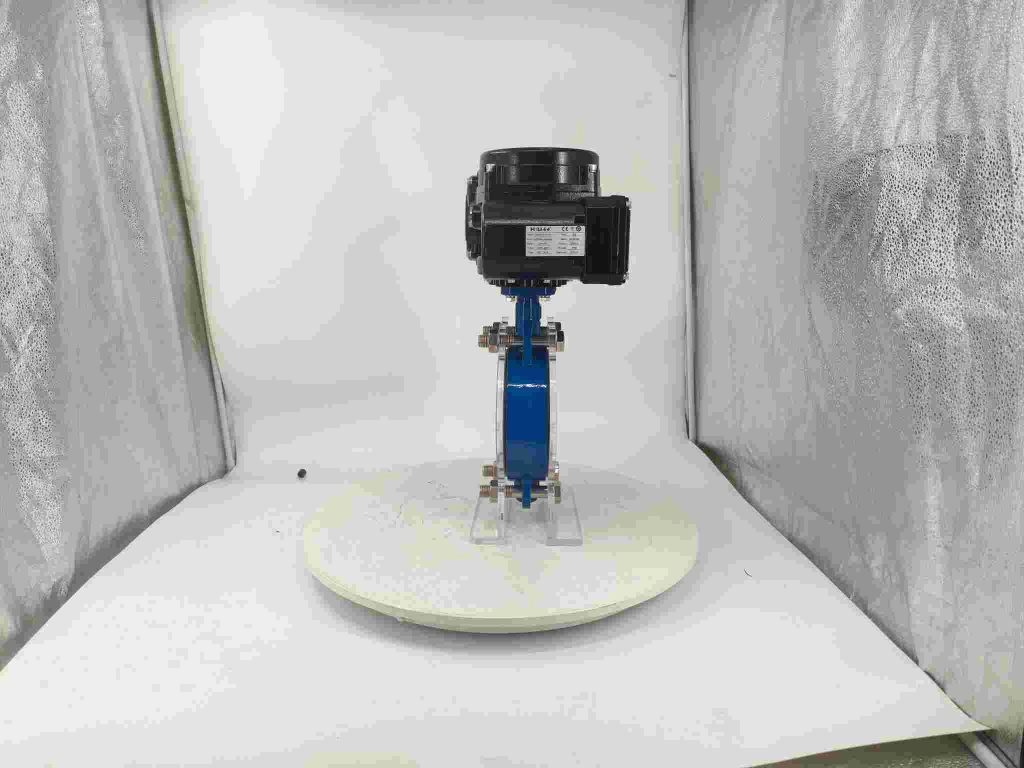

Explosion-proof electric butterfly valves are specifically engineered for use in hazardous environments, such as chemical processing plants, oil refineries, and wastewater treatment facilities. Their primary function is to control the flow of fluids while ensuring that any electrical components do not ignite surrounding flammable materials. These valves offer several advantages: Safety: The primary benefit of explosion-proof valves is enhanced safety. They are designed to withstand high pressures and temperatures, reducing the risk of accidents in volatile environments. Efficiency: Electric butterfly valves provide quick and precise flow control, improving the efficiency of industrial processes. Their design allows for smooth operation, minimizing turbulence and ensuring a consistent flow rate.