Injection molding, a crucial process in the manufacturing industry, has revolutionized the way we produce plastic parts. With its ability to create intricate and complex shapes with precision and efficiency, injection molding has become synonymous with reliability and durability. This article explores the ins and outs of injection molded parts, their various applications, and the reasons why they are so ubiquitous in today’s world.

The Injection Molding Process

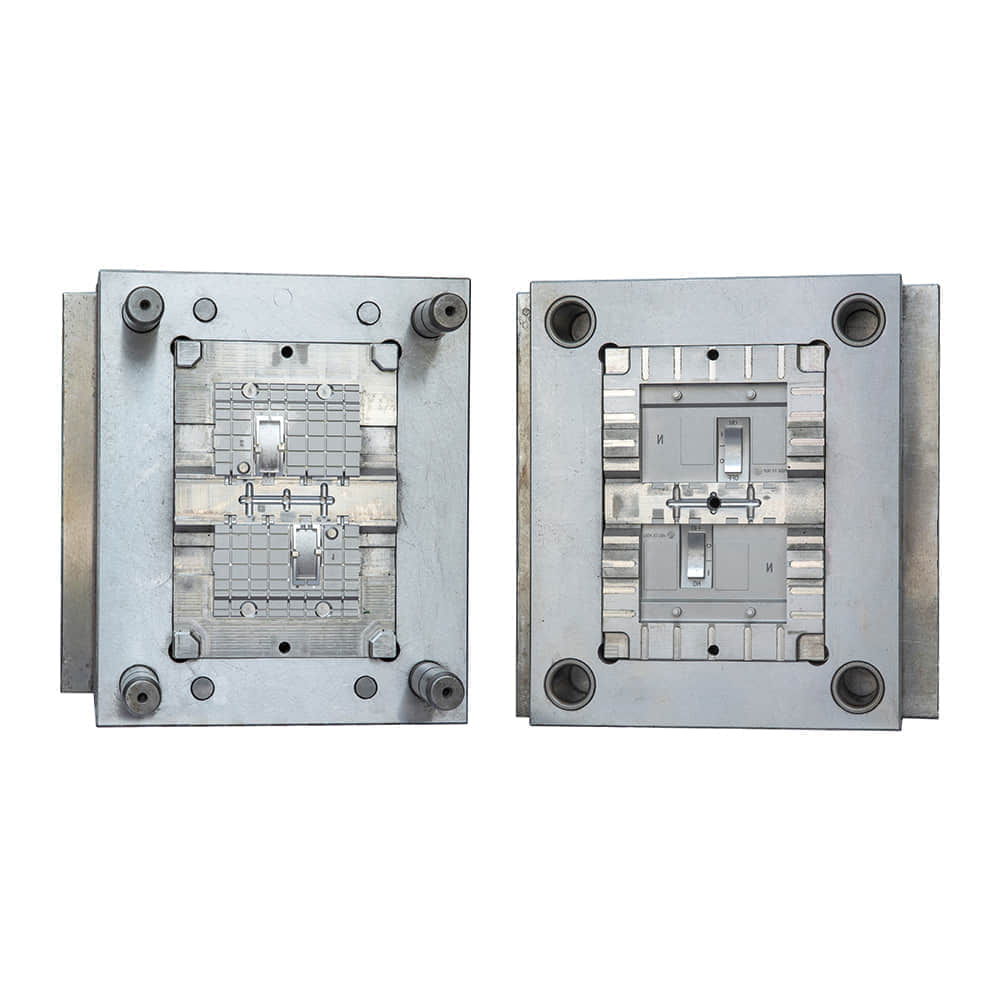

Injection molding begins with a thermoplastic or thermosetting plastic material. This material is fed into an injection molding machine, where it is heated to a molten state. Under high pressure, the molten plastic is then injected into a precision-designed mold. The mold, which is cooled to ensure rapid solidification of the plastic, is shaped to create the desired form of the part. Once the plastic has cooled and solidified, the mold is opened, and the injection molded part is ejected. Advantages of Injection Molded Parts Injection molded parts offer several advantages that make them ideal for a wide range of applications. Firstly, the process is highly efficient, allowing for mass production of identical parts in a relatively short time. Secondly, the precision of the molds ensures that each part produced is dimensionally accurate, ensuring consistency and reliability. Additionally, the material used in injection molding can be customized to meet specific requirements, such as durability, resistance to chemicals, or electrical insulation.