In the fast-paced world of modern manufacturing, where efficiency, precision, and cost-effectiveness are paramount, the role of Progressive Die cannot be overstated. This advanced form of stamping tool has revolutionized the production of complex metal parts, transforming the way manufacturers approach large-scale production runs.

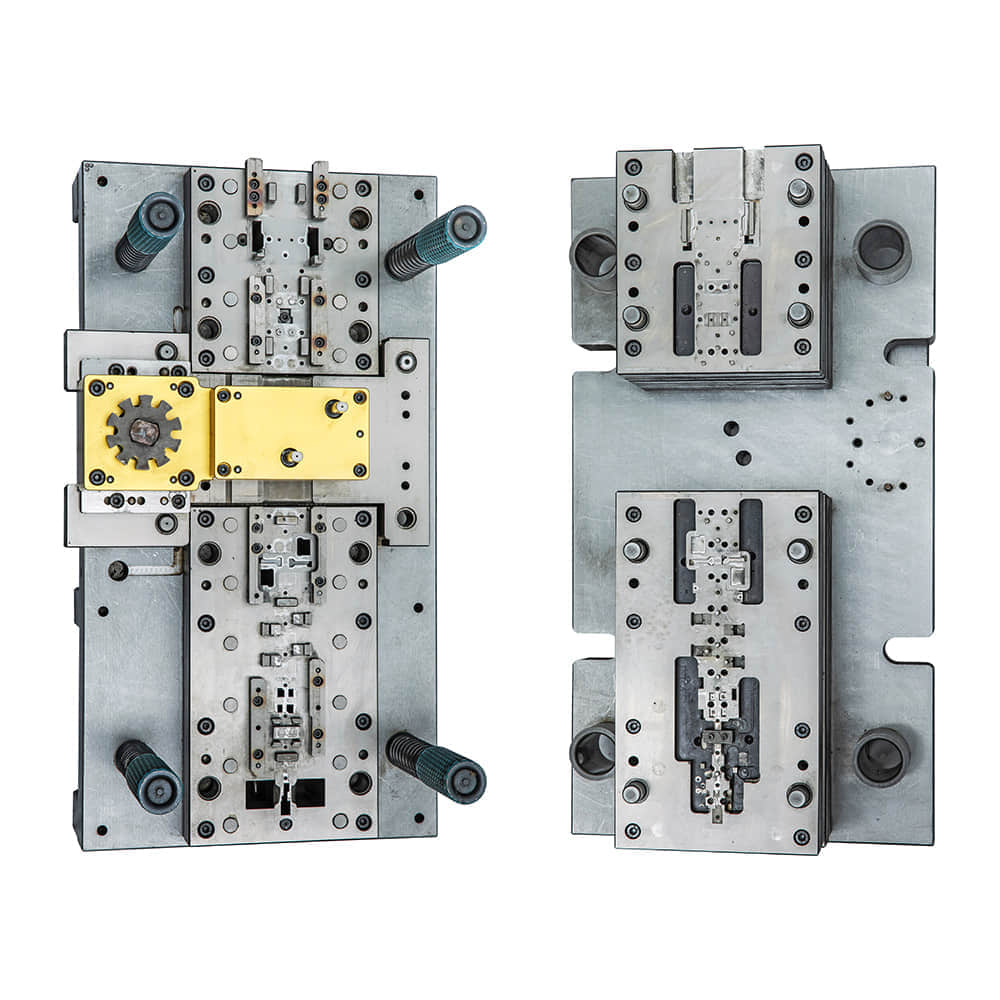

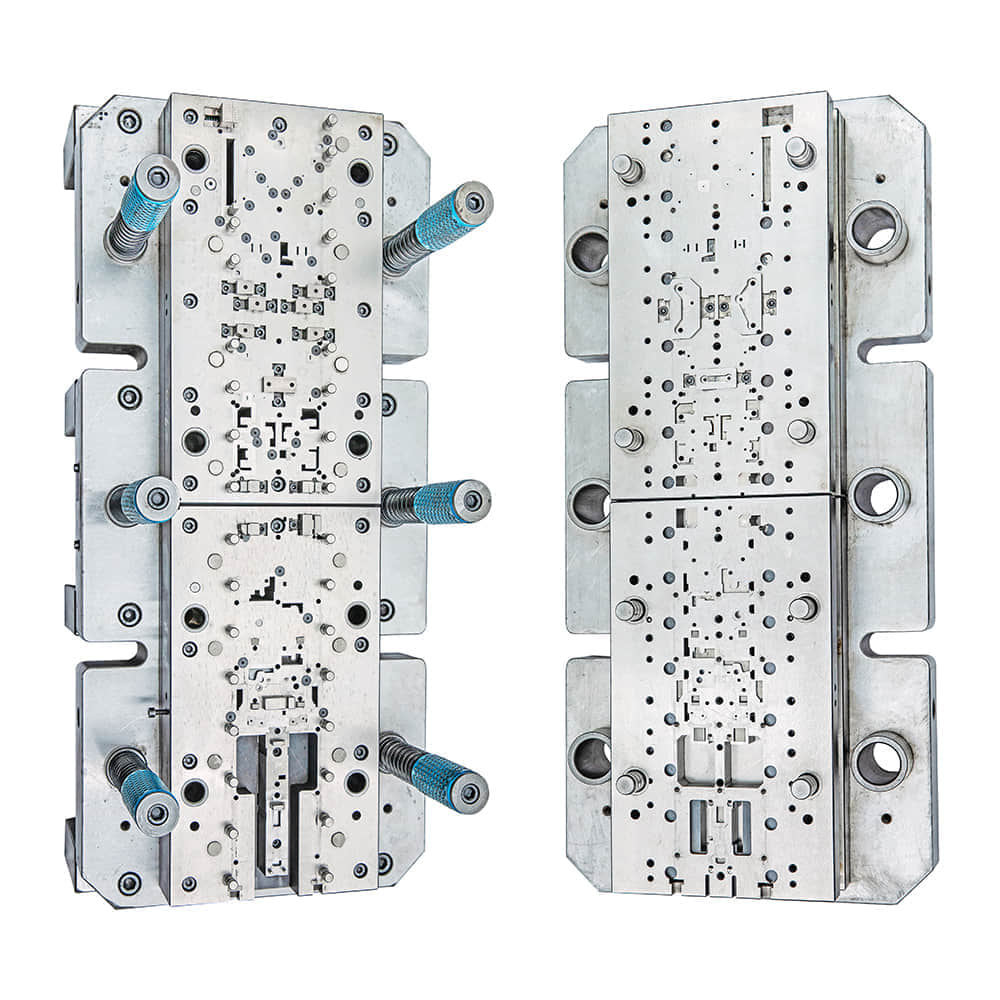

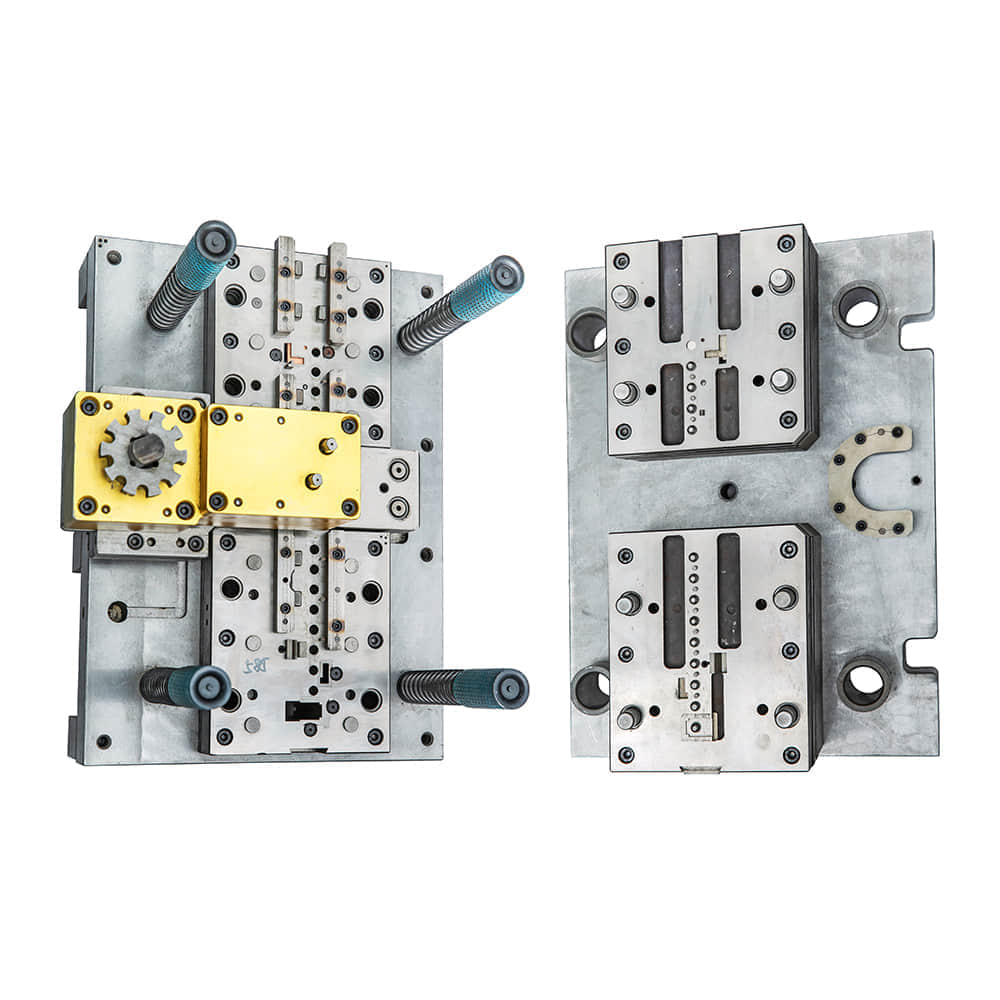

Progressive Die, also known as a sequential die or a continuous die, is a sophisticated machinery that integrates multiple operations into a single, automated process. Each station within the die performs a specific task, such as punching, bending, or trimming, on a continuously fed strip of material. As the strip progresses through the die, it undergoes a series of transformations, gradually taking shape into the final product.

The allure of Progressive Die lies in its unparalleled efficiency. By consolidating multiple steps into a single pass, it significantly reduces cycle time and labor costs. This streamlined approach not only accelerates production speeds but also ensures consistency and accuracy across every part produced. The automation of the process further minimizes human error, enhancing overall quality control. Moreover, Progressive Die technology is highly flexible, accommodating a wide range of materials and designs. From delicate electronics components to heavy-duty automotive parts, this versatile tool can be tailored to meet the unique requirements of various industries. Its modularity allows for easy adjustments and optimizations, ensuring that manufacturers can quickly adapt to market changes or customer demands.