Injection molded parts manufacturers play a crucial role in the modern manufacturing landscape. This industry specializes in creating precise and complex components for a variety of applications, from automotive parts to consumer electronics. Understanding the process, benefits, and market trends associated with injection molding can provide valuable insights into why these manufacturers are so pivotal in today’s economy.

The Injection Molding Process

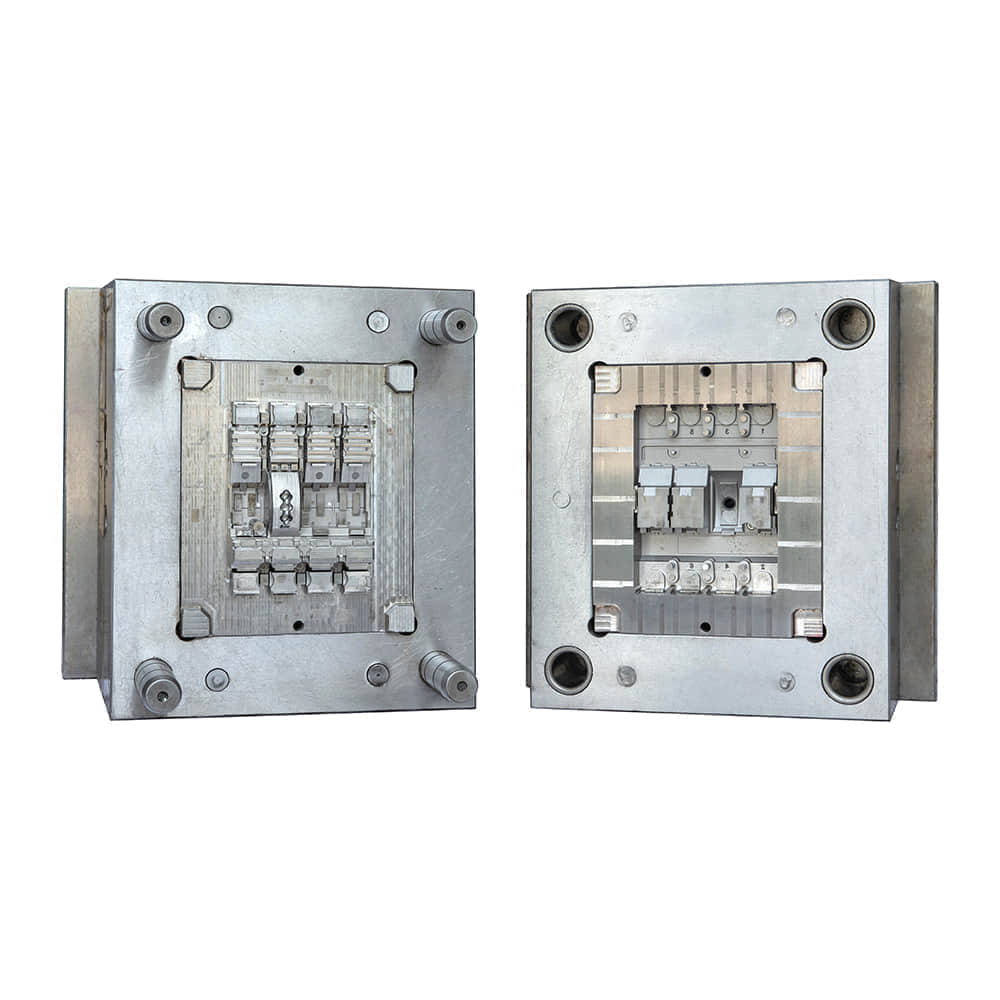

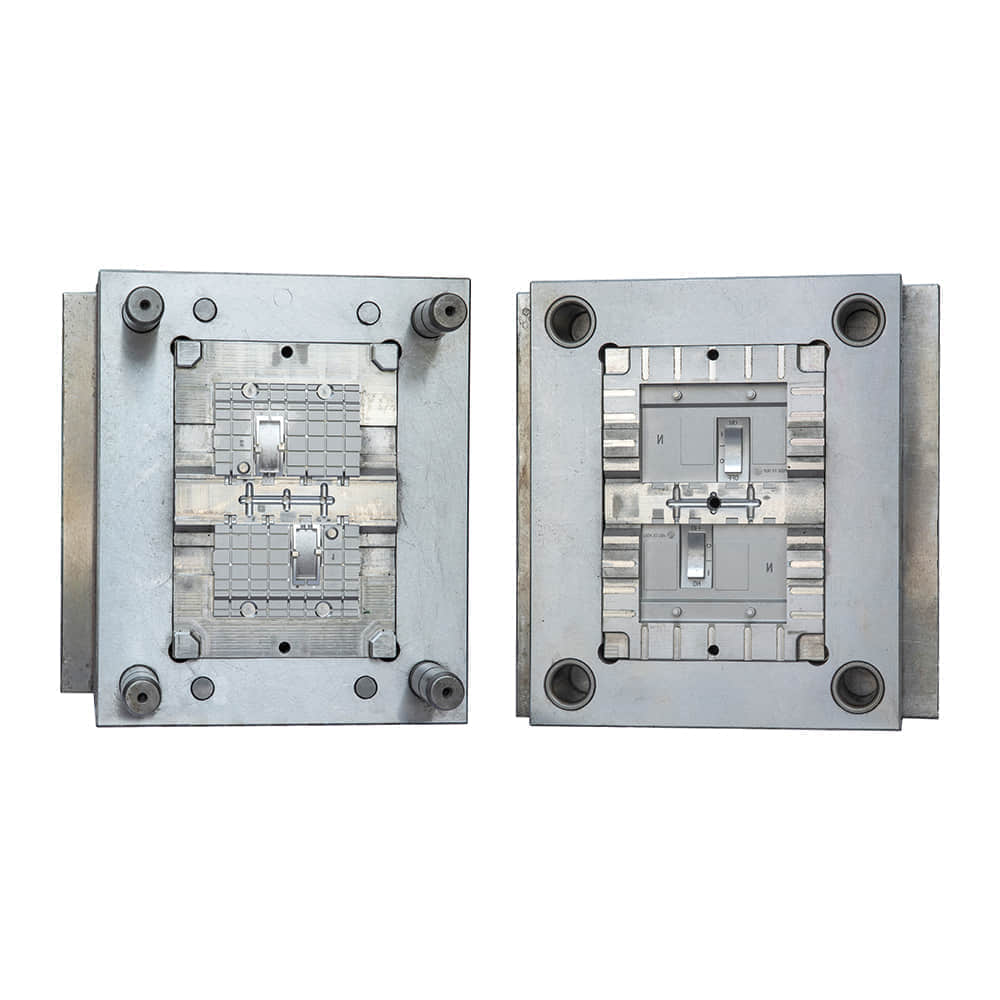

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. The process involves several key steps: Design and Prototyping:The journey begins with the design of the part, often using CAD (Computer-Aided Design) software. A prototype is created to test the design’s functionality and fit. Mold Creation:Once the design is finalized, a mold is created from materials like steel or aluminum. The mold is crafted with precision to ensure that the final part will meet the required specifications. Injection:Molten material, typically plastic, is injected into the mold under high pressure. This material is heated until it reaches a liquid state, then forced into the mold cavity.