In the realm of modern manufacturing, the Blanking Die stands as a pivotal tool, enabling precise and efficient cutting of materials to desired shapes and sizes. This indispensable component of the stamping process finds widespread application across various industries, from automotive to electronics, contributing significantly to the overall efficiency and quality of products.

At its core, the Blanking Die is a specialized tool designed to perform the crucial task of blanking. Blanking, a form of stamping, involves the separation of a workpiece from its sheet metal stock by means of a sharp cutting edge. The Blanking Die, therefore, must be meticulously crafted to ensure a clean and precise cut, minimizing material waste and maximizing product integrity.

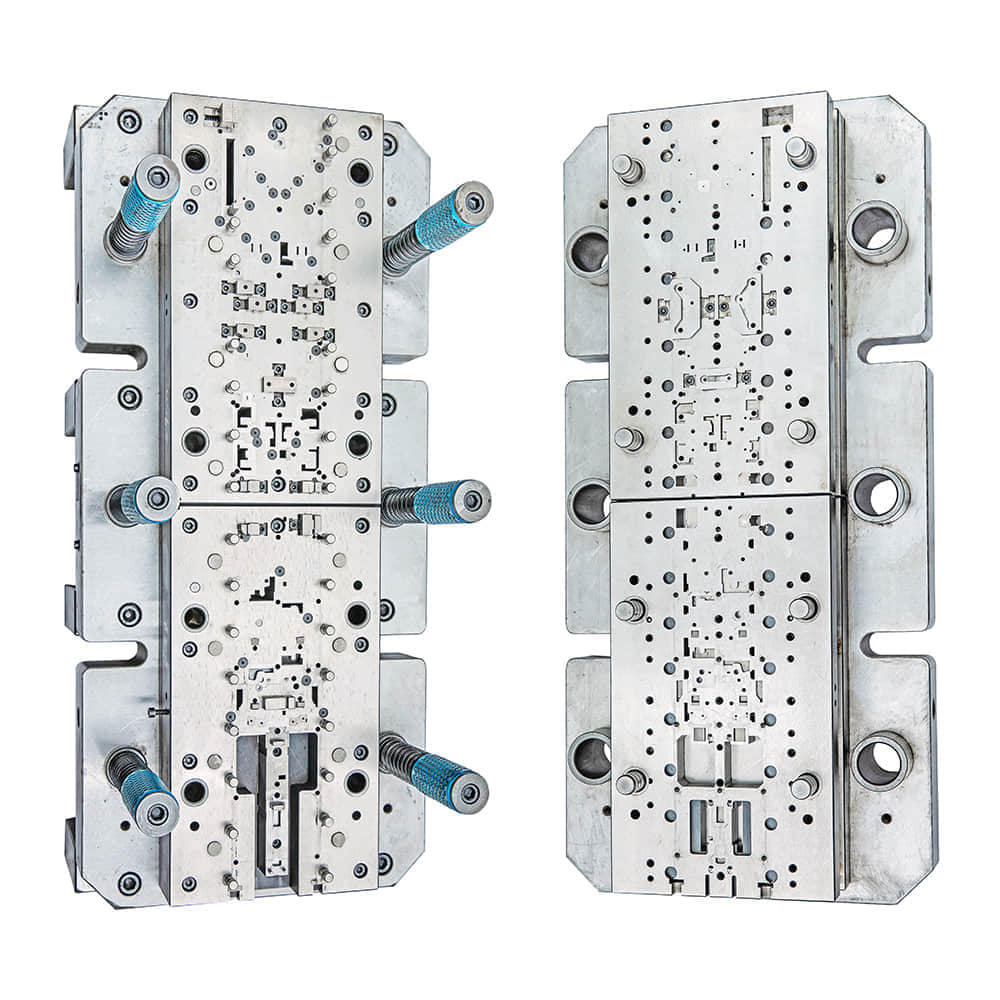

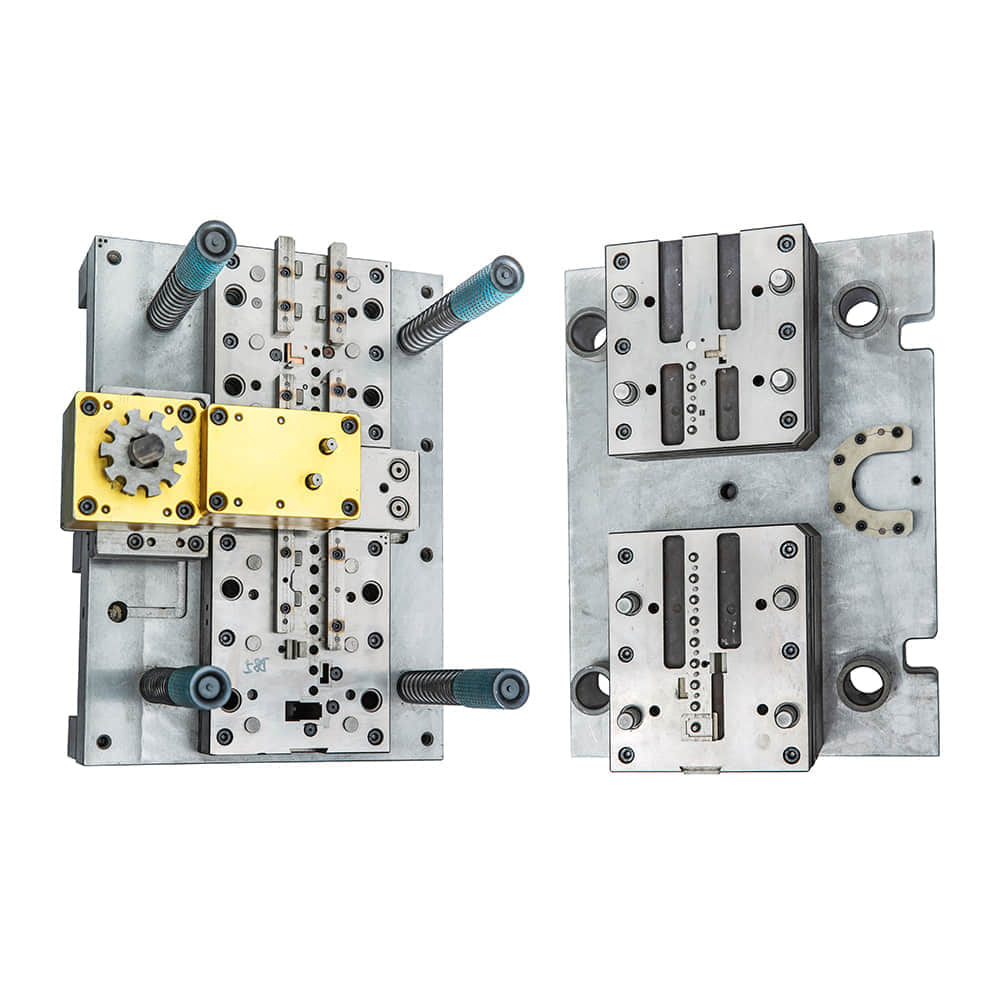

The design and construction of a Blanking Die are intricate processes that require a deep understanding of materials, mechanics, and manufacturing techniques. The die is typically composed of several key components, including the punch, die cavity, and ejector mechanism. The punch, a sharp-edged tool, is responsible for the actual cutting action, while the die cavity provides a guiding surface for the punch and holds the workpiece securely in place. The ejector mechanism, on the other hand, facilitates the removal of the cut workpiece from the die after the stamping operation. The choice of materials for the Blanking Die is crucial, as it directly affects the die’s durability, precision, and overall performance. High-strength steel alloys are commonly used due to their excellent wear resistance and ability to maintain sharp cutting edges over extended periods of use. Additionally, the surface finish of the die components is carefully controlled to minimize friction and ensure smooth operation.