The Explosion-proof Electric Butterfly Valve, a pivotal component in industrial fluid control systems, plays a crucial role in ensuring the safe and efficient operation of processes in hazardous environments. Its unique design combines the functionality of an electric actuator with the safety features required for explosion-proof applications, making it an indispensable tool in industries such as petrochemical, chemical, and pharmaceutical manufacturing.

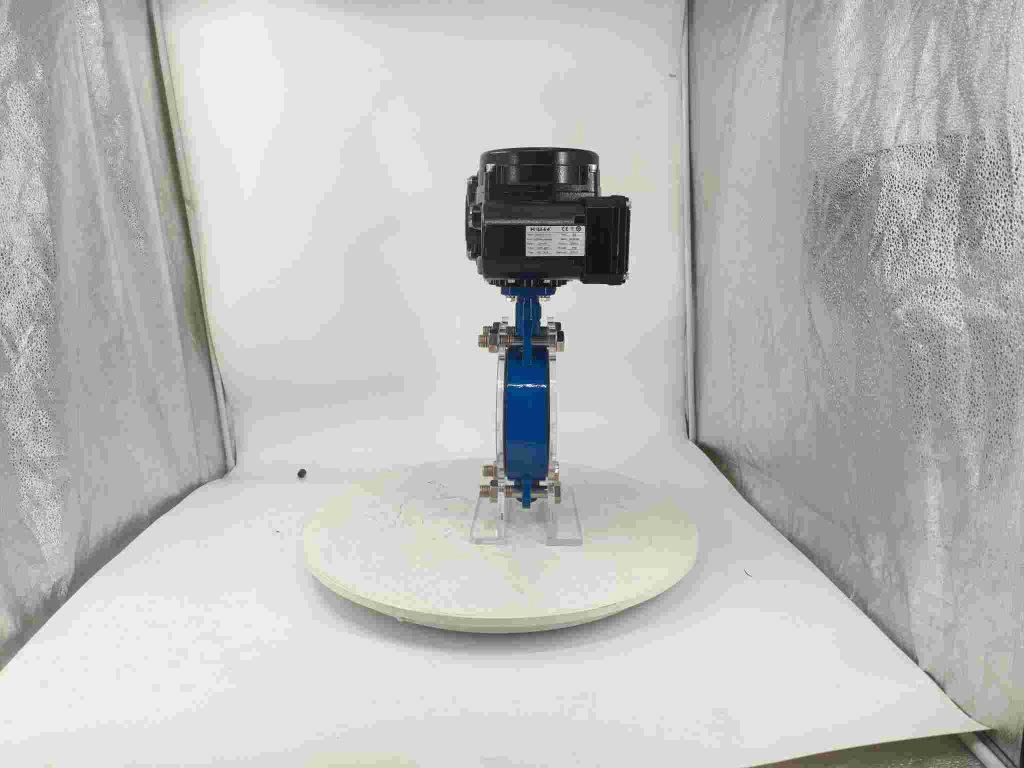

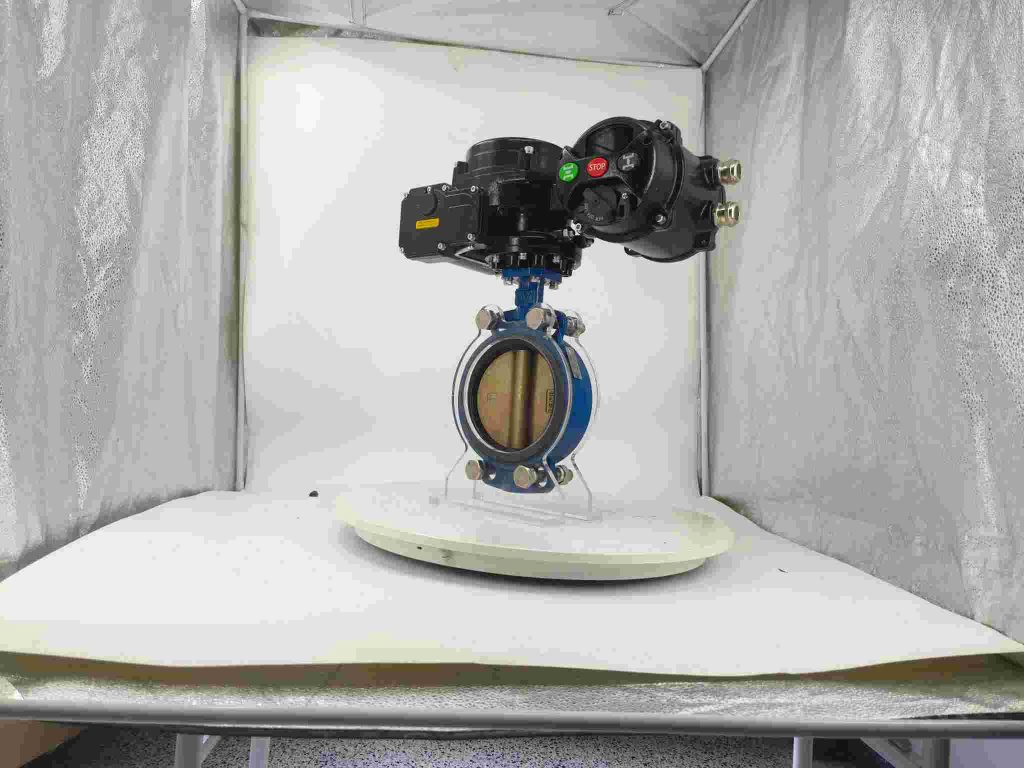

The core of the Explosion-proof Electric Butterfly Valve lies in its electric actuator, which provides the power and precision necessary to control the valve’s opening and closing. This actuator is designed to withstand the rigors of explosive atmospheres, featuring special electrical components and insulation materials that prevent the ignition of surrounding gases or dust. The actuator’s responsive and reliable performance ensures accurate fluid control, even under extreme conditions.

The butterfly valve itself is a compact and lightweight design, making it suitable for installation in tight spaces. Its disc-shaped closure element rotates within the valve body to regulate fluid flow, providing a smooth and efficient operation. The valve’s material selection is also crucial, as it must be compatible with the corrosive or flammable fluids it is intended to control. The integration of explosion-proof features into the Electric Butterfly Valve ensures its safe operation in environments where ignition sources pose a significant risk. These features include the use of explosion-proof enclosures for electrical components, as well as special gaskets and seals that prevent the ingress of gases or dust. These measures significantly reduce the likelihood of a spark or ignition occurring, thus minimizing the risk of explosions.