Progressive Dies: Revolutionizing Manufacturing Efficiency

In the world of manufacturing, efficiency is the key to success. Among the many tools and technologies available to manufacturers, progressive dies have emerged as a game-changer. These sophisticated tools have transformed the way products are manufactured, enhancing productivity, precision, and cost-effectiveness. In this article, we will delve into the world of progressive dies, exploring their functionality, applications, and the benefits they bring to various industries.

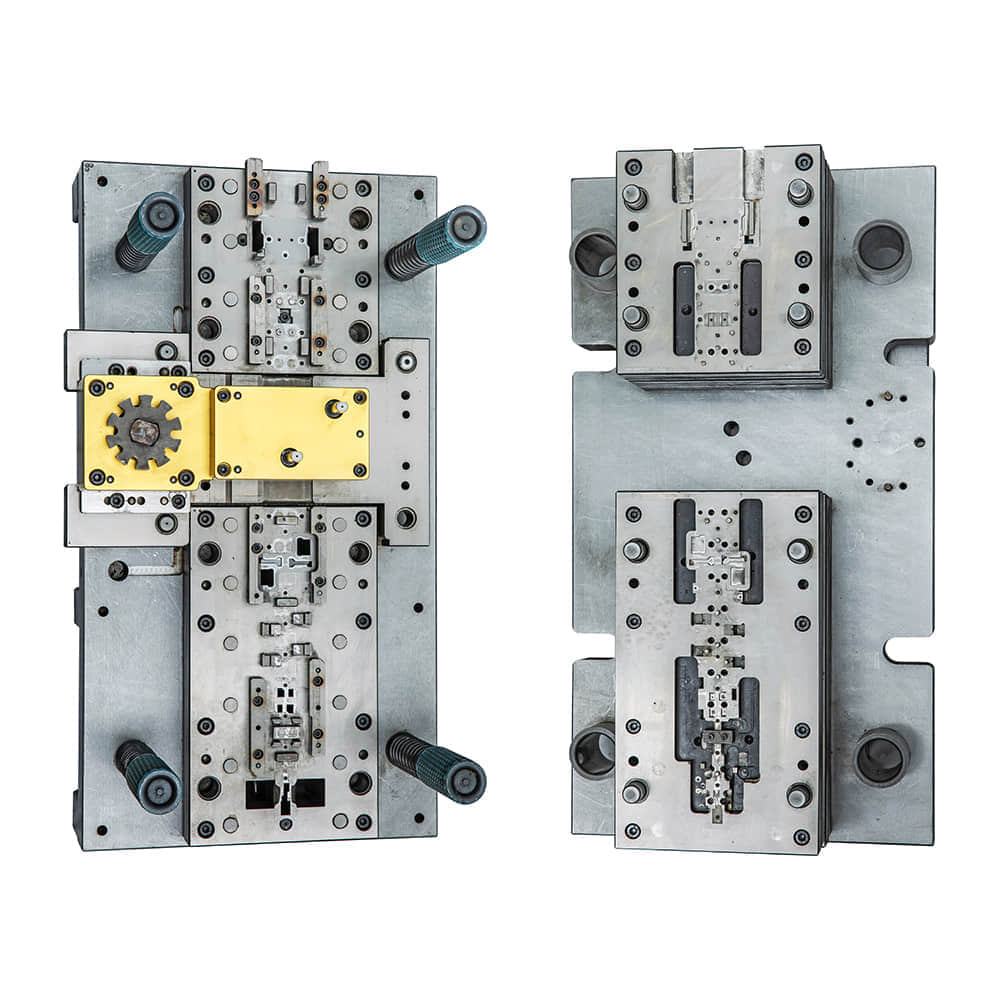

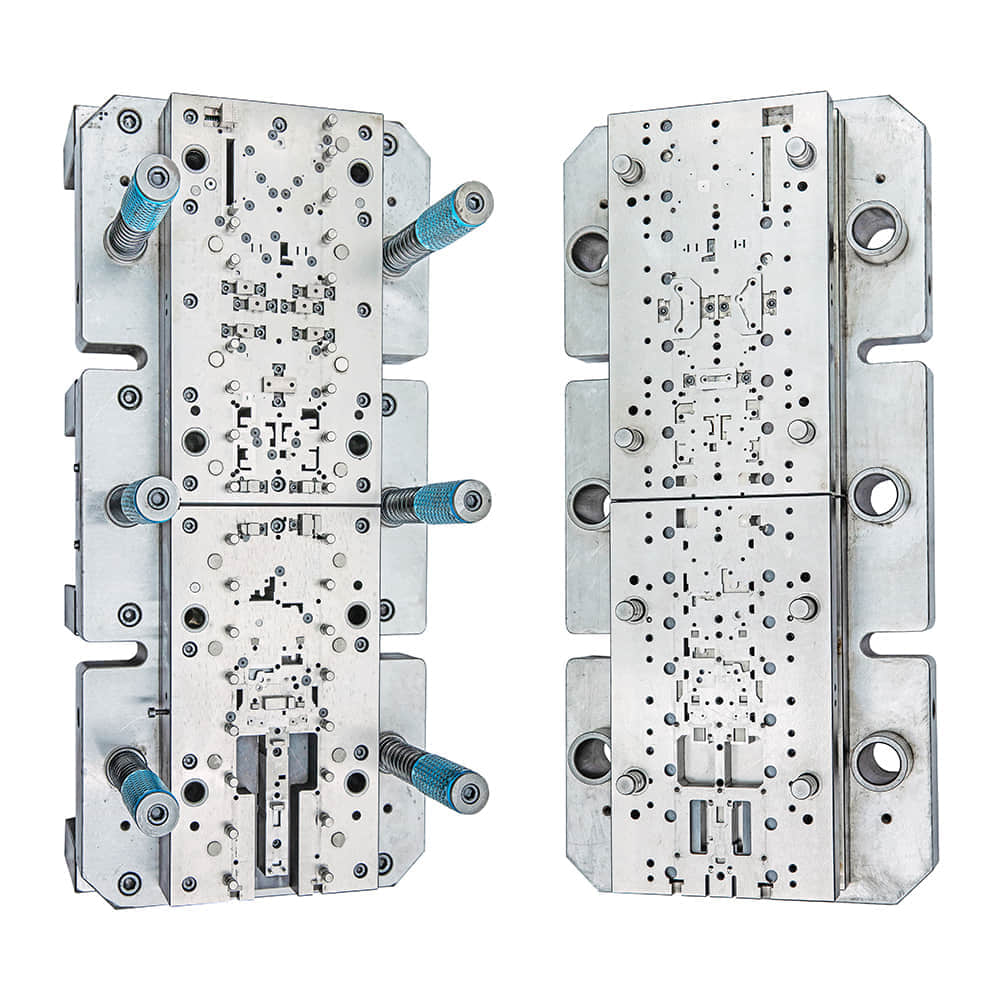

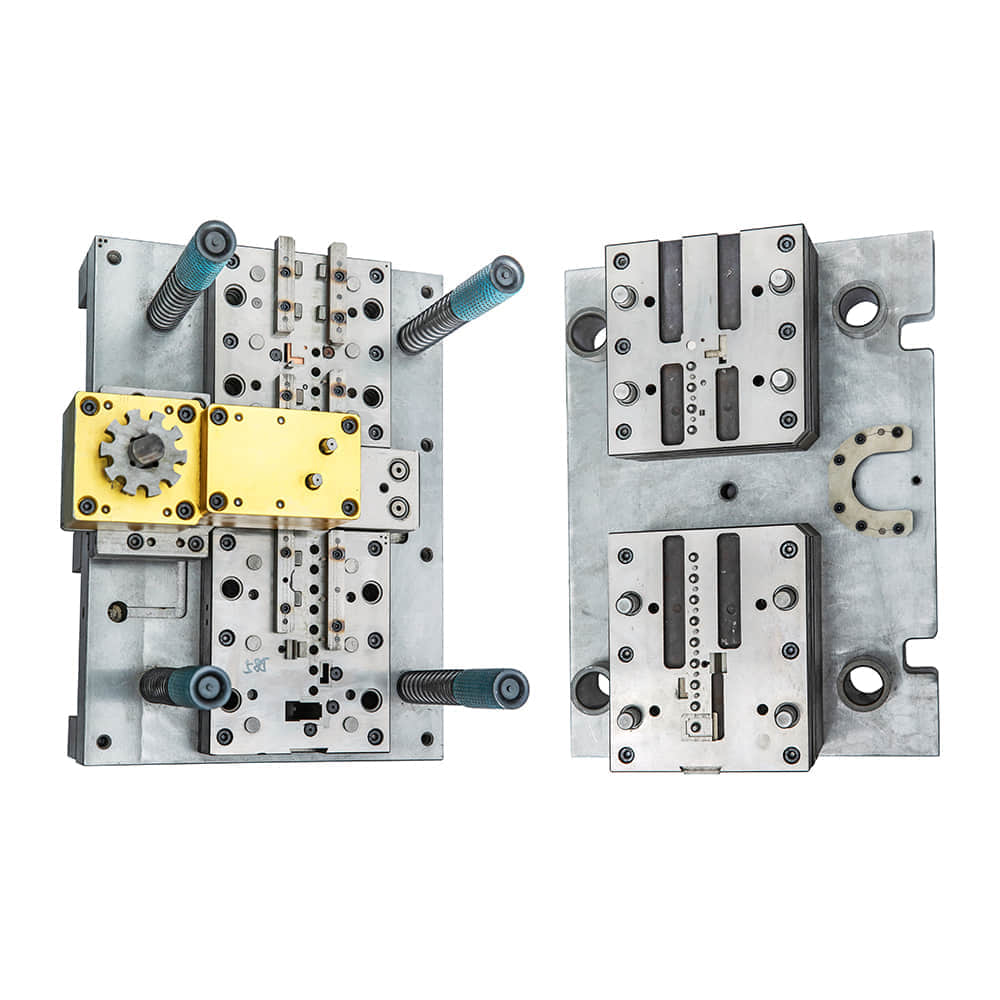

Understanding Progressive Dies Progressive dies are specialized tools used in metalworking and stamping processes. They are designed to streamline the production of parts with complex shapes, such as brackets, connectors, and electrical components. What sets progressive dies apart from other die types is their ability to perform multiple operations in a single pass, significantly reducing production time and labor costs. The Anatomy of a Progressive Die A progressive die consists of multiple stations, each equipped with a unique tool or die component. These stations work together in a synchronized manner to transform a flat metal strip or coil into a finished part. The die components may include piercing punches, blanking dies, bending dies, and more, depending on the complexity of the part being produced. The Progressive Die Process Feeding: The process begins with a metal strip or coil being fed into the die. Precision is crucial here, as the strip must be advanced to the correct position for each operation. Piercing and Blanking: In the initial stations, the die pierces holes and blanks out the desired shapes from the metal strip. Bending and Forming: Subsequent stations bend and form the metal, giving it the required shape. Trimming: Additional trimming stations may be included to remove any excess material or sharp edges. Extraction: Finally, the finished part is extracted from the strip, while the scrap material is typically carried away for recycling. Applications Across Industries Progressive dies find applications in a wide range of industries, thanks to their versatility and efficiency: 1. Automotive: Progressive dies are extensively used in the automotive industry to produce components such as brackets, clips, and electrical connectors. The high precision and rapid production capabilities of progressive dies are critical in meeting the demands of this fast-paced industry. 2. Electronics: In the electronics sector, where miniature parts are common, progressive dies enable the mass production of intricate components like connectors, contact pins, and sockets. 3. Appliances: Manufacturers of household appliances rely on progressive dies to create components like hinges, latches, and brackets, ensuring consistent quality and cost-effectiveness. 4. Aerospace: In the aerospace industry, where safety and precision are paramount, progressive dies are employed to produce components for aircraft and spacecraft, including brackets, fasteners, and structural elements. 5. Consumer Goods: Progressive dies are used to craft various consumer goods, from zippers and buttons in the fashion industry to intricate parts for toys and games. Benefits of Progressive Dies The adoption of progressive dies offers several notable advantages to manufacturers: 1. Increased Efficiency: Progressive dies dramatically reduce production time by performing multiple operations in one pass, leading to higher productivity. 2. Precision and Consistency: These dies offer exceptional precision, ensuring that each part meets exact specifications. This consistency is vital in industries where safety and reliability are paramount. 3. Cost Savings: The reduction in labor costs and material waste makes progressive dies a cost-effective choice for high-volume production. 4. Faster Time-to-Market: Manufacturers can respond quickly to changing market demands due to the rapid production capabilities of progressive dies. 5. Versatility: Progressive dies can be adapted for various applications, making them a versatile tool for different industries and product types. Conclusion Progressive dies represent a remarkable advancement in manufacturing technology, offering unprecedented efficiency and precision across a wide range of industries. As manufacturers continue to seek ways to optimize their processes and reduce costs, the role of progressive dies in shaping the future of production is set to expand further. These versatile tools are not just driving efficiency; they are transforming the way we create products, making them an indispensable asset in the modern manufacturing landscape.