Introduction

Injection molded parts play a pivotal role in modern manufacturing, shaping industries ranging from automotive and electronics to consumer goods and medical devices. This article explores the key aspects, advancements, and diverse applications of injection molded parts.

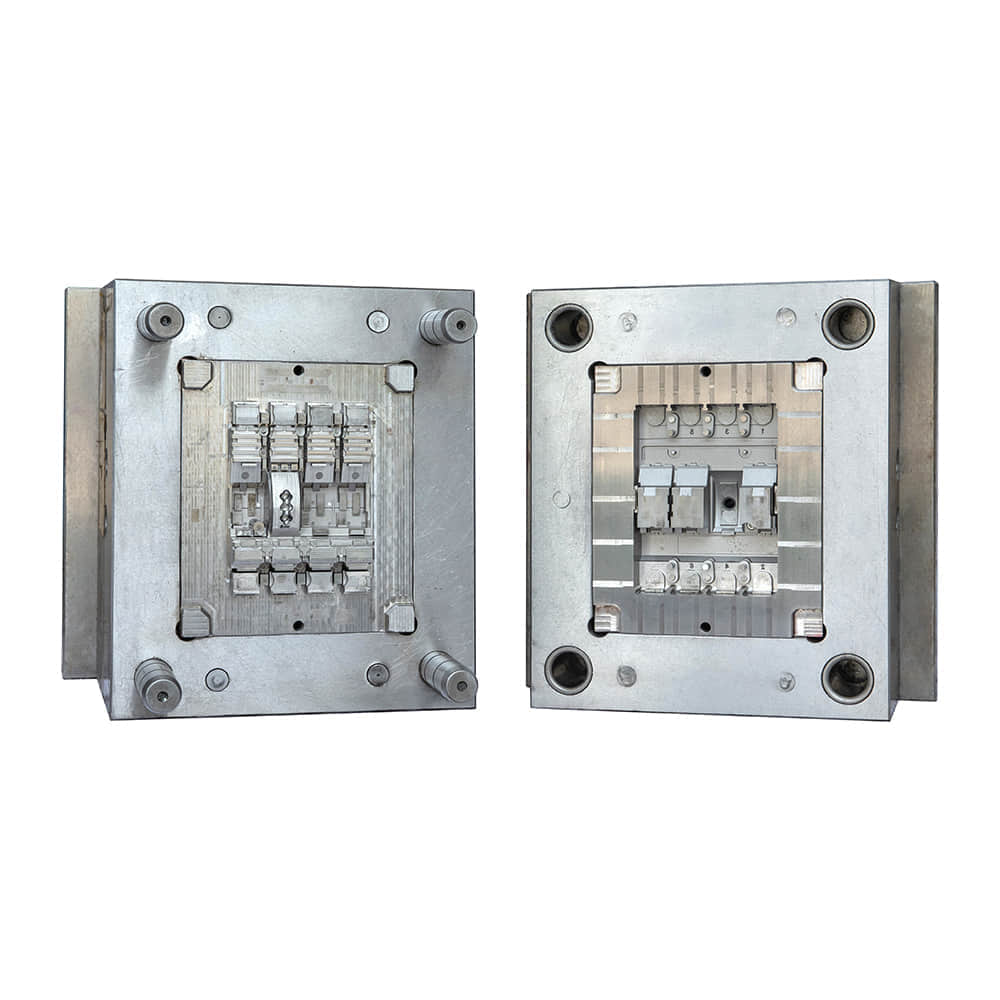

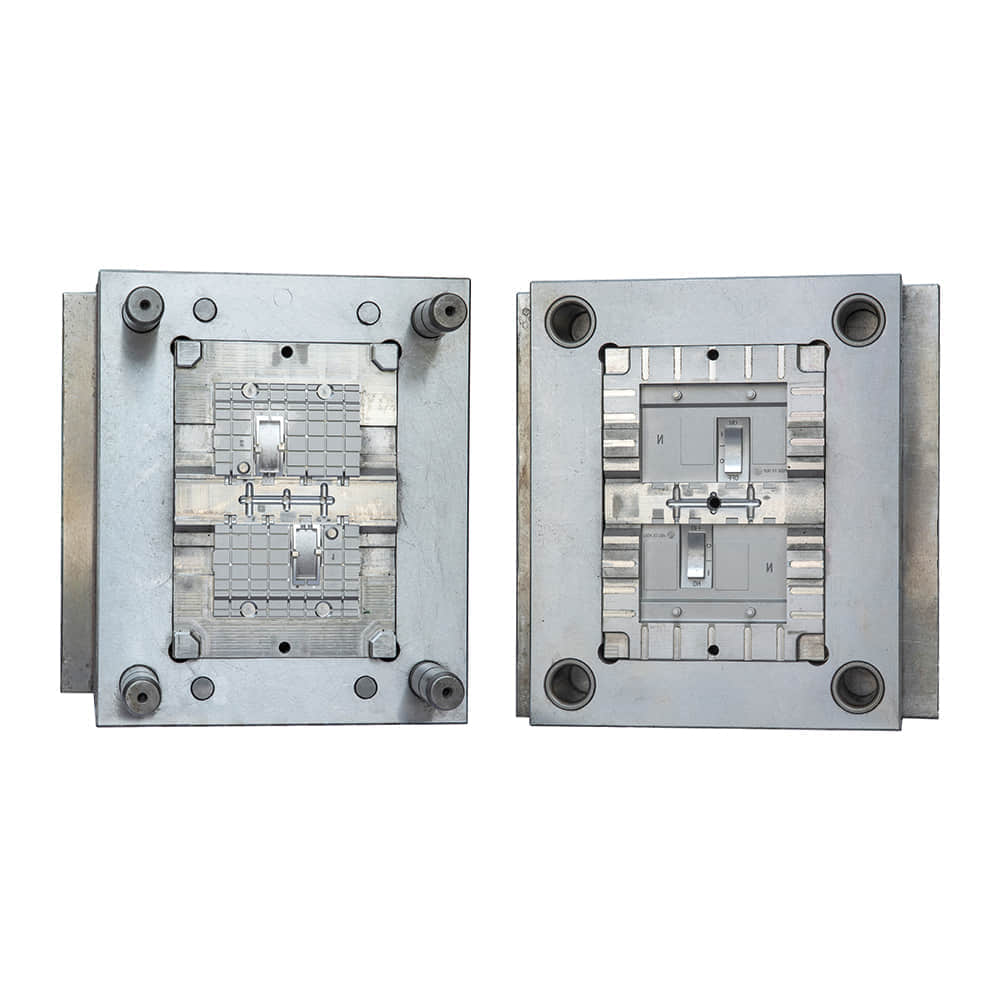

The Injection Molding Process Injection molding is a widely used manufacturing process that involves injecting molten material, often thermoplastics, into a mold cavity. Once the material cools and solidifies, the mold is opened, and the final product is ejected. This process allows for the efficient and precise production of complex geometries and intricate details. Advancements in Injection Molding Materials: Over the years, a broad range of materials has been developed for injection molding, including engineering-grade polymers, bioplastics, and even composite materials. These materials exhibit enhanced mechanical properties, improved heat resistance, and environmental sustainability, expanding the potential applications of injection molded parts. Technology: Advanced technologies, such as computer-aided design (CAD) software and simulation tools, enable manufacturers to design intricate molds and optimize the injection molding process. This leads to reduced cycle times, minimized waste, and higher product consistency. Automation and Robotics: Automation and robotics have revolutionized injection molding. Automated systems can handle tasks like material preparation, mold changing, and quality inspection. This not only boosts efficiency but also ensures higher precision and reduces human error. Micro Injection Molding: The miniaturization of electronic components and medical devices has driven the development of micro injection molding. This process allows for the production of tiny parts with extremely tight tolerances, enabling innovations in sectors like medical implants and microelectronics. Applications of Injection Molded Parts Automotive Industry: Injection molded parts are widely used in the automotive sector, from interior components like dashboards and door panels to critical under-the-hood parts. Their durability, cost-effectiveness, and design flexibility make them an integral part of vehicle manufacturing. Consumer Electronics: The sleek designs and intricate shapes of consumer electronic devices are often made possible by injection molded parts. These parts house delicate electronics, provide structural support, and contribute to the overall aesthetics of the products. Medical Devices: Injection molded parts are crucial in the medical field due to their biocompatibility and precision. They are used in medical equipment, disposable devices, and even implants. The use of advanced materials has further facilitated the production of sterile and reliable medical components. Packaging: Many types of packaging, such as bottles, containers, and caps, are manufactured using injection molding. This method offers efficient mass production of consistent and lightweight packaging solutions. Toys and Games: The toy industry benefits from injection molded parts as they allow for the rapid production of intricate and colorful components. From action figures to board game pieces, injection molding enables cost-effective and safe toy manufacturing. Conclusion Injection molded parts have transformed manufacturing by offering a combination of versatility, precision, and efficiency. With ongoing advancements in materials, technology, and automation, the scope of injection molding continues to expand across industries. From automotive and electronics to healthcare and consumer goods, injection molded parts are an indispensable driving force behind innovation and product development.