Key Differences between Stainless Steel and Plastic Solenoid Valves:

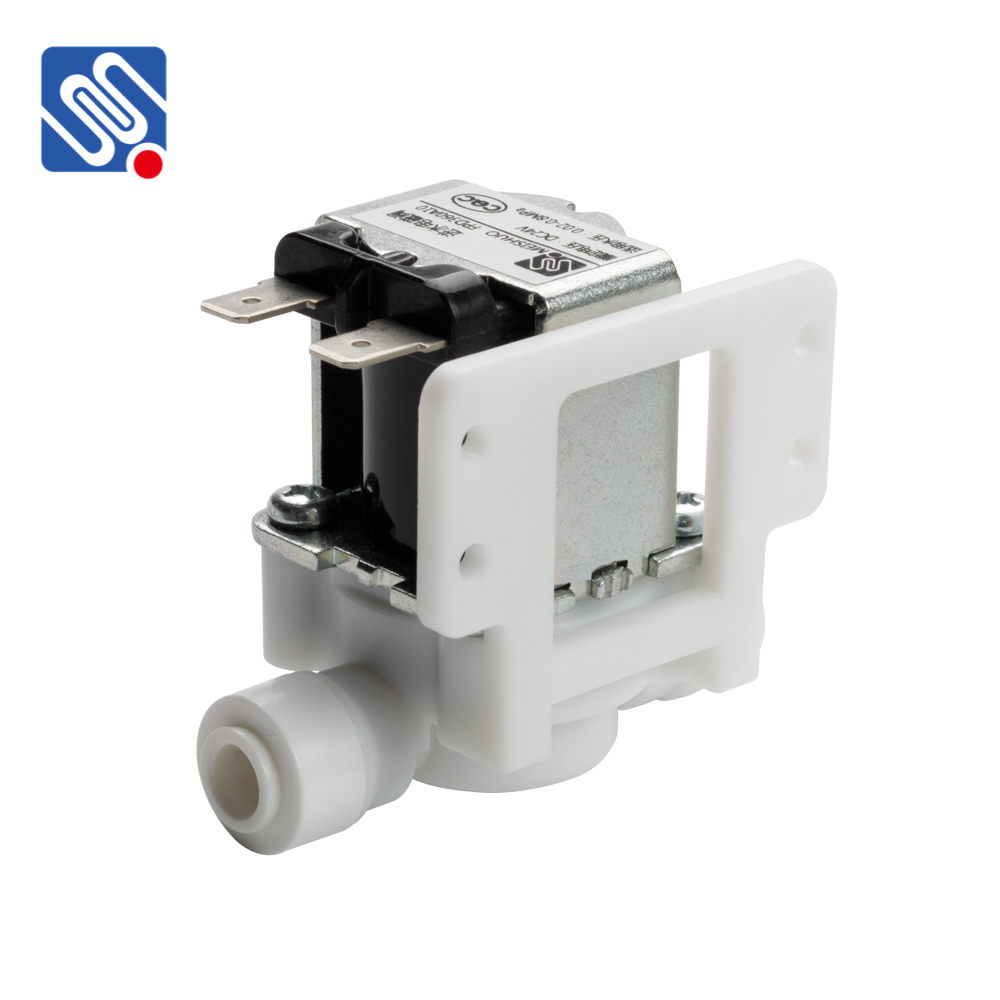

Material Construction: Stainless Steel Solenoid Valve: These valves are made from stainless steel, making them highly durable, corrosion-resistant, and able to withstand high pressure and temperature conditions. They are suitable for aggressive environments, such as chemical or industrial applications. Plastic Solenoid Valve: These are made from plastic materials (such as PVC, PTFE, or polypropylene), which makes them more affordable and lightweight. They are ideal for use in environments where corrosion is a concern, but where the pressure and temperature are not as extreme as in stainless steel applications.