Solenoid valves are essential components in fluid control systems, providing automatic regulation of the flow of liquids and gases. These valves are activated by an electric current, allowing for precise control in a variety of industrial processes. Among the materials commonly used for solenoid valves, stainless steel and plastic are two of the most prevalent choices. Both offer distinct advantages and are suited to different applications based on their unique properties. This article will delve into the differences, advantages, and applications of stainless steel and plastic solenoid valves, highlighting when and why each material is the best option.

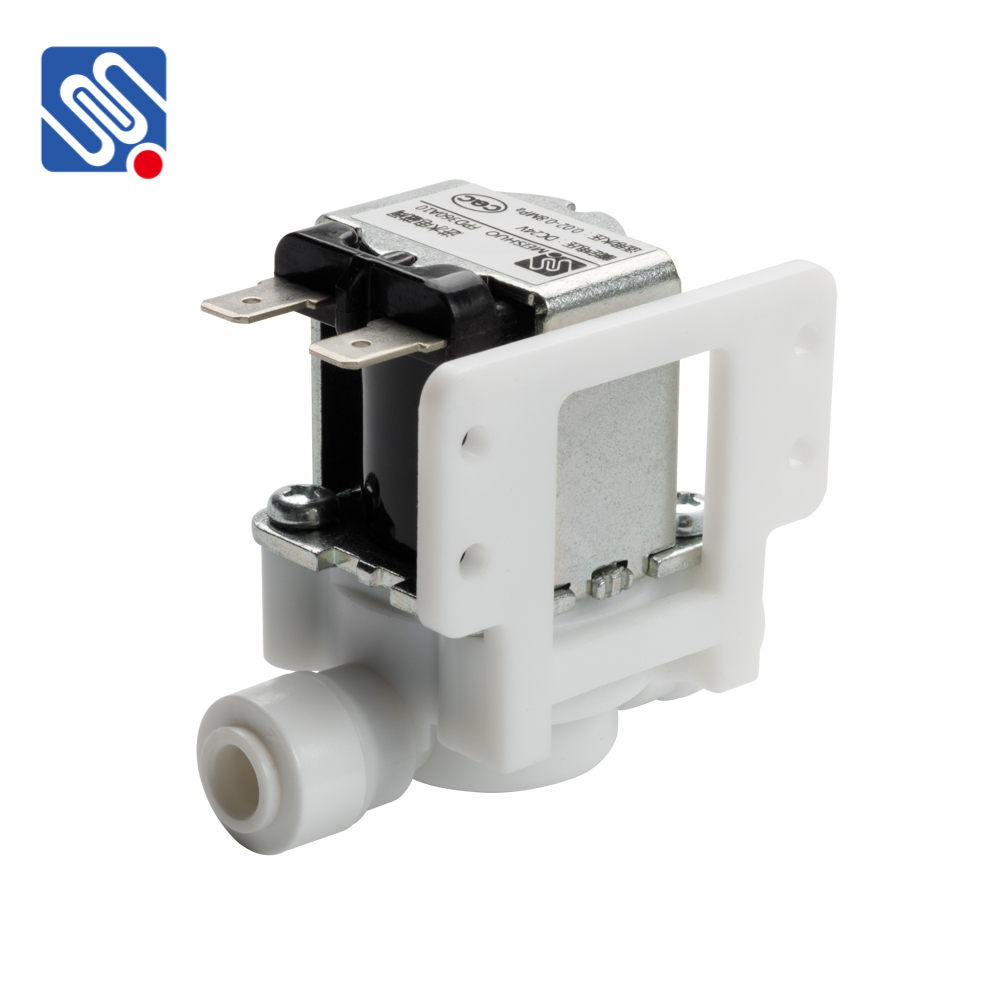

What Are Solenoid Valves? Solenoid valves consist of an electrically controlled valve mechanism that opens and closes based on the activation of a solenoid. When electricity is applied, the magnetic field of the solenoid shifts the valve’s internal parts, either opening or closing the passage for fluid. This simple yet highly efficient mechanism allows for quick response times, making solenoid valves integral to systems requiring precise and automatic flow control, such as in water treatment, automation, and HVAC systems. Stainless Steel Solenoid Valves: Strength and Durability Stainless steel solenoid valves are widely recognized for their strength and resistance to harsh conditions. Made from high-quality alloys such as 304 or 316 stainless steel, these valves are suitable for applications that demand durability, high pressure, and temperature tolerance. The primary benefit of using stainless steel in solenoid valves is its exceptional resistance to corrosion. This makes them an ideal choice for handling aggressive fluids like acids, alkalis, and other corrosive chemicals.