Progressive Die: Revolutionizing Manufacturing Efficiency

Introduction

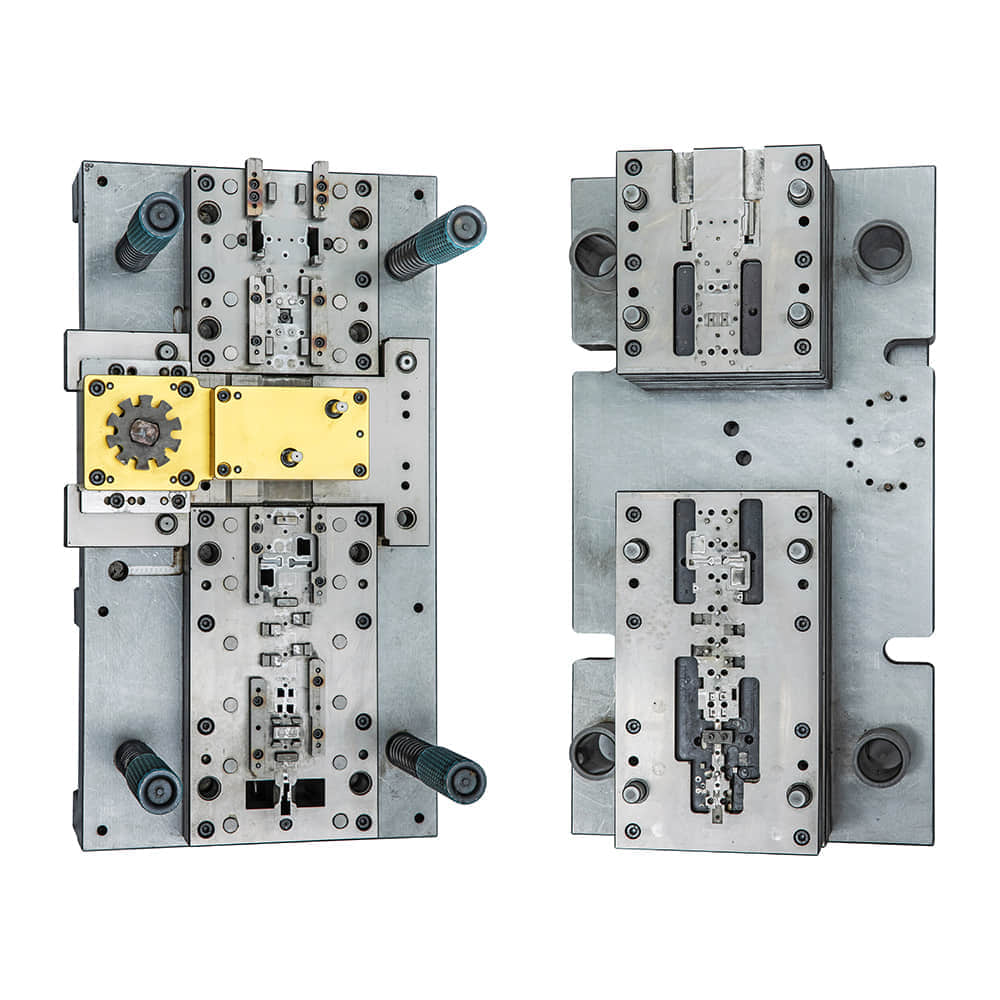

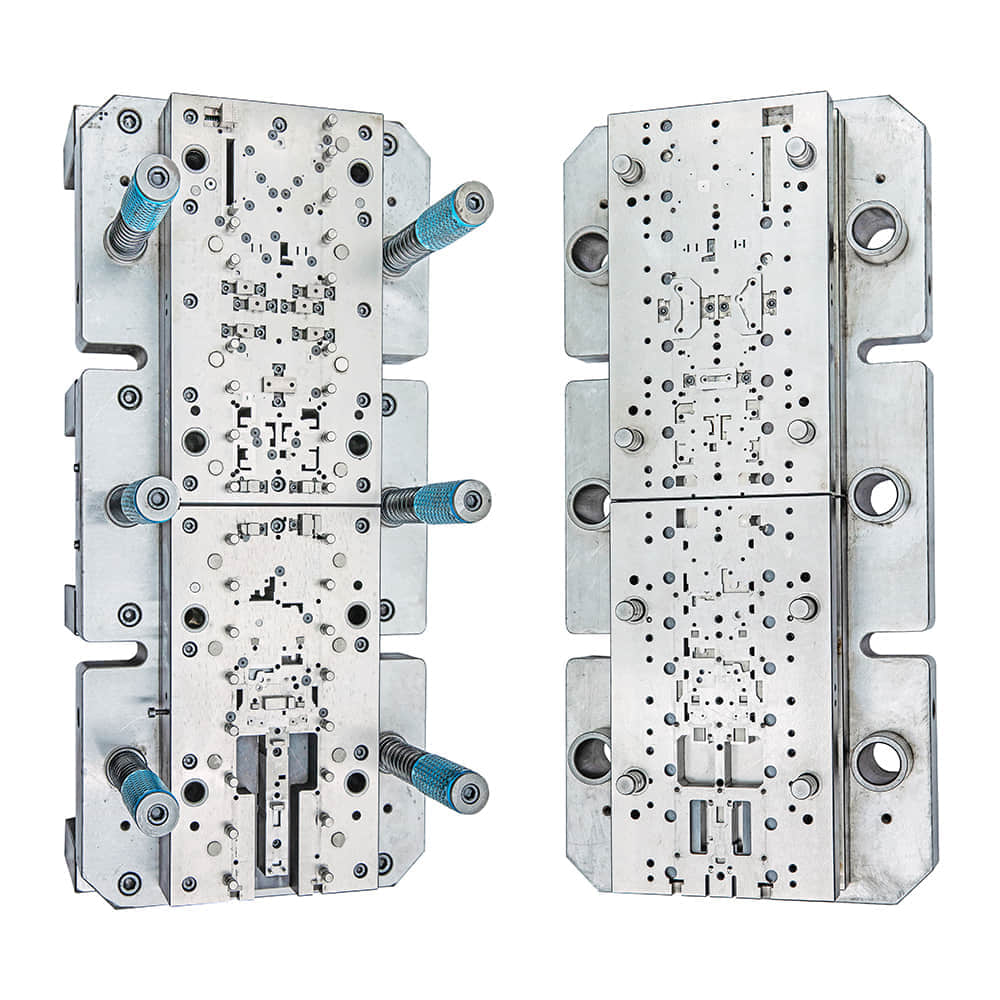

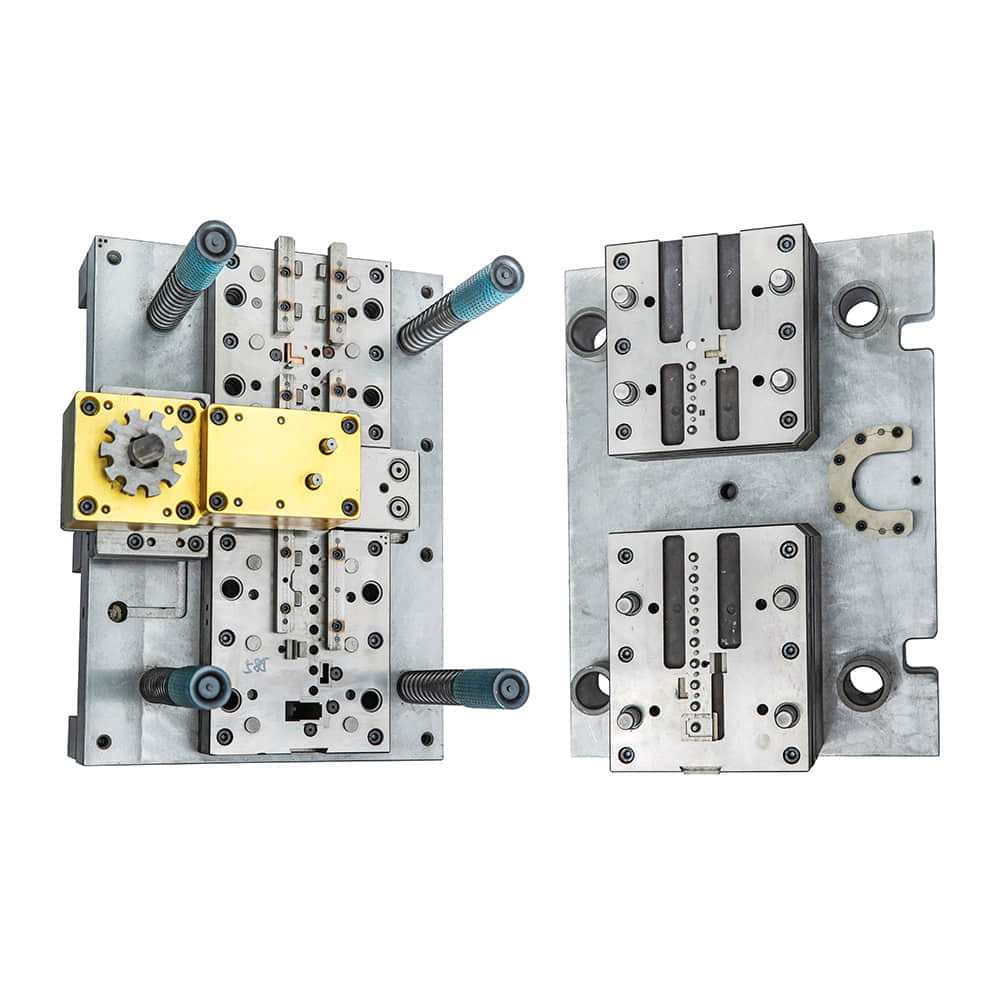

In the dynamic world of manufacturing, efficiency and precision are paramount. One of the key innovations that have significantly transformed the industry is the progressive die. This intricate tool, often hidden from plain sight, plays a vital role in shaping metal and other materials into a wide array of products. In this article, we will delve into the world of progressive dies, exploring their design, functionality, and the numerous advantages they offer to modern manufacturing processes. Understanding Progressive Dies A progressive die is a specialized tool used in metal stamping and forming processes. Unlike conventional dies, which perform a single operation on a material sheet, progressive dies perform multiple operations simultaneously as the material passes through a series of stations within the die. Each station is designed to carry out a specific task, such as cutting, bending, or shaping, contributing to the gradual transformation of the raw material into a finished product. The Anatomy of a Progressive Die A typical progressive die comprises several key components, each with a specific role in the manufacturing process: Entry Material Guide:The first station, the entry material guide, ensures that the raw material enters the die accurately and consistently. This is critical to maintaining precision throughout the process. Piercing and Blanking Stations:These stations are responsible for cutting out the desired shapes from the material. They use sharp cutting edges to remove excess material, leaving behind the intended part. Bending Stations:As the material progresses, it encounters bending stations. These stations use punches and dies to bend the material into the desired angles and shapes. Drawing Stations:In cases where deep drawing is necessary, drawing stations use powerful forces to pull the material into a recessed die cavity, creating intricate shapes and forms. Coining Stations:Coining stations refine the surface finish and dimensions of the part by applying significant pressure. This ensures the final product meets tight tolerances. Progression Mechanism:The progression mechanism controls the movement of the material through the die, ensuring that each station operates in sequence. Advantages of Progressive Dies Progressive dies offer several significant advantages over traditional manufacturing methods: High Efficiency:Progressive dies perform multiple operations in a single pass, drastically reducing production time compared to sequential processing. Consistency:The automated nature of progressive dies ensures consistent quality and precision across all produced parts. Reduced Scrap:Minimal material wastage is achieved through precise cutting and forming operations, resulting in cost savings. Cost-Effective:While the initial setup of a progressive die can be costly, it offers significant long-term savings through increased production rates and reduced labor costs. Complex Parts:Progressive dies excel in producing complex parts with tight tolerances, which can be challenging to achieve with other methods. Applications of Progressive Dies Progressive dies find applications in a wide range of industries, including automotive, aerospace, electronics, and consumer goods. They are used to manufacture a variety of products such as: Automotive Components:Progressive dies are commonly used to produce intricate parts like brackets, clips, and connectors for the automotive industry. Electronics:In the electronics sector, progressive dies are employed to manufacture connectors, terminals, and shielding components. Home Appliances:Progressive dies play a pivotal role in creating components for appliances like refrigerators, washing machines, and air conditioners. Medical Devices:The medical device industry benefits from progressive dies for crafting precise components such as surgical instruments and implantable devices. Conclusion Progressive dies are an engineering marvel that has revolutionized the world of manufacturing. Their ability to streamline operations, maintain high precision, and reduce production costs makes them indispensable in today’s competitive market. As technology continues to advance, we can expect progressive dies to evolve further, pushing the boundaries of what is possible in modern manufacturing.