In today’s industrial landscape, the art of injection molding plays a pivotal role in manufacturing processes across a myriad of industries. The unsung heroes behind this intricate process are injection mold manufacturers, who craft the essential molds that bring products to life. In this article, we delve into the fascinating world of injection mold manufacturers, uncovering the science, craftsmanship, and innovation that define their work.

The Backbone of Manufacturing

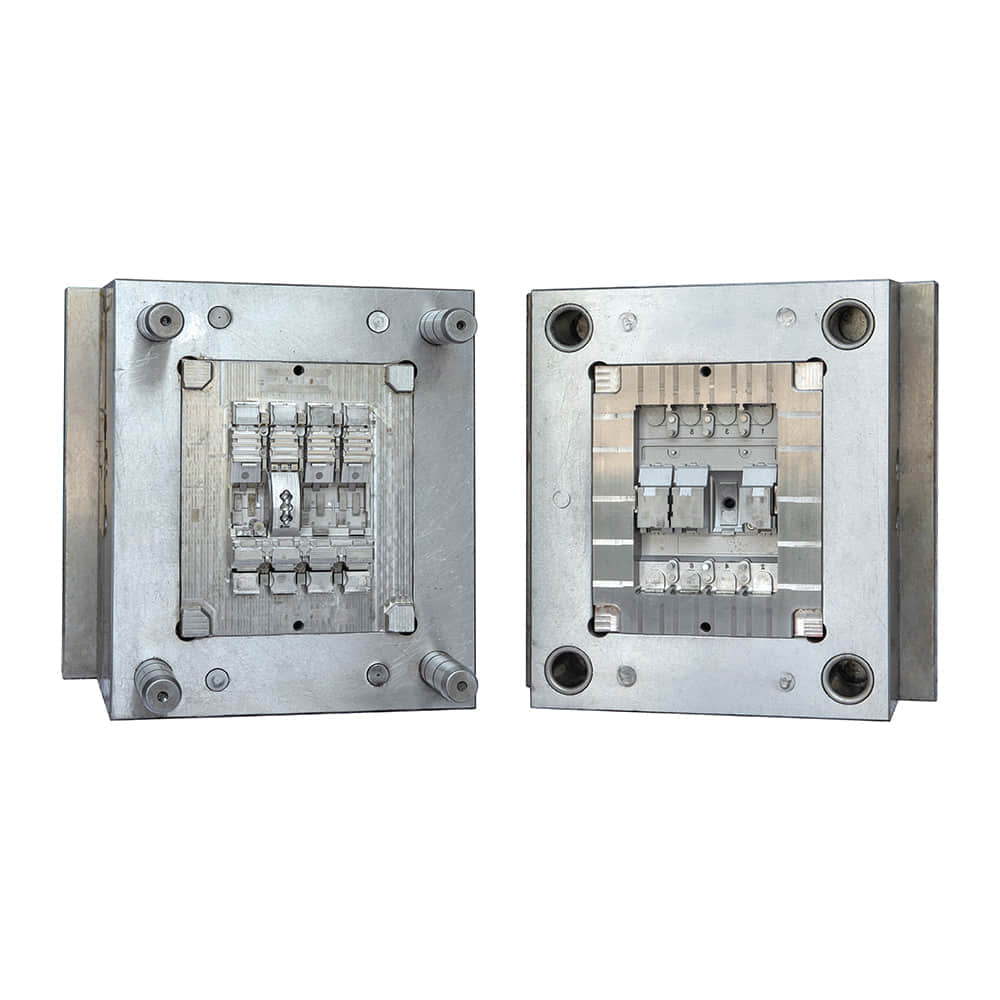

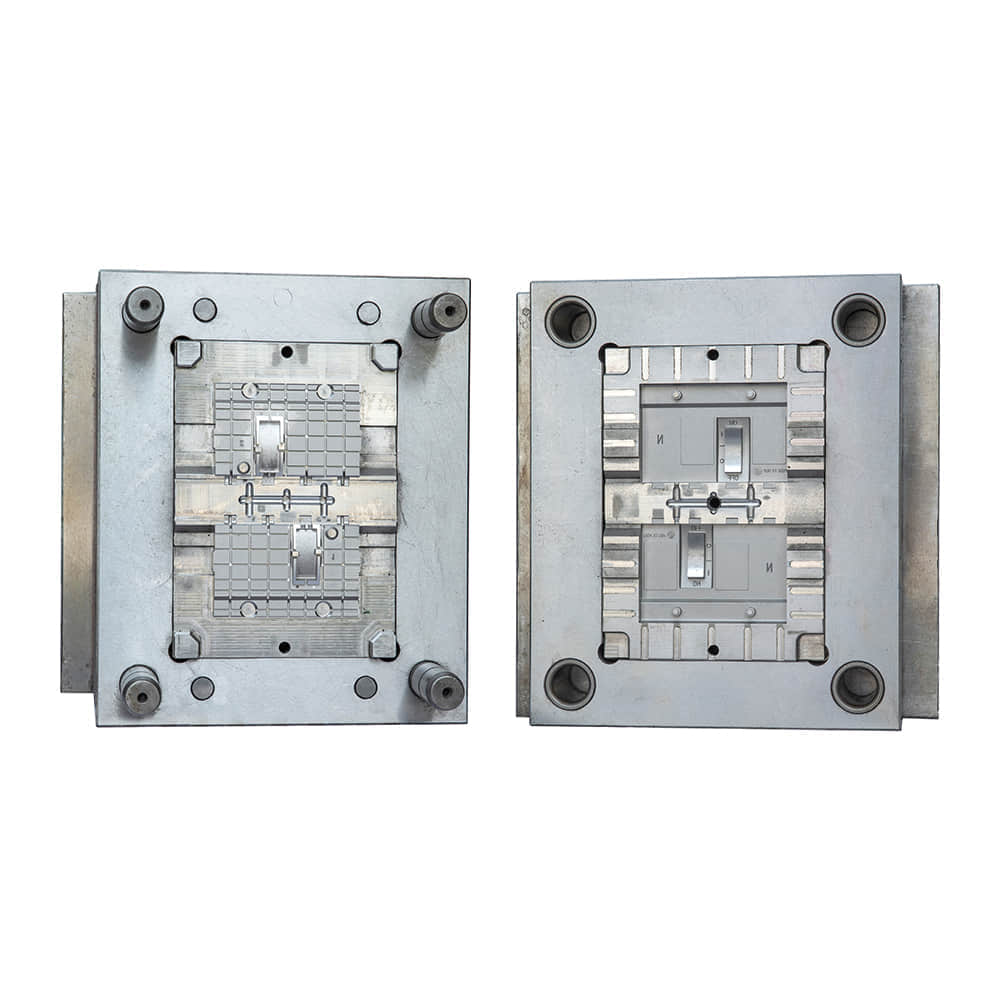

Injection molding is a manufacturing process that involves the injection of molten material into a carefully designed mold cavity. This process is used to produce a wide range of products, from intricate medical devices to everyday plastic items like bottle caps. The precision and quality of these molds are instrumental in determining the final product’s performance and appearance. The Art of Design One of the first steps in injection mold manufacturing is the design of the mold itself. Skilled engineers and designers meticulously craft these molds, taking into account factors such as material properties, product geometry, and production volume. Modern computer-aided design (CAD) software and cutting-edge simulation tools enable manufacturers to create highly precise molds that meet the most stringent requirements. Materials Matter Selecting the right material for an injection mold is crucial. Molds must withstand high temperatures and pressures while maintaining dimensional stability. Common materials include hardened steel, aluminum, and even reinforced plastics for less demanding applications. The choice of material depends on factors like production volume, material to be molded, and budget constraints. Craftsmanship and Precision Once the mold design is finalized, the real craftsmanship begins. Highly skilled toolmakers meticulously machine the mold components with precision and accuracy. This involves intricate milling, grinding, and EDM (Electrical Discharge Machining) processes. The result is a mold that can withstand the rigors of mass production while producing consistent, high-quality parts. Cutting-Edge Technology Injection mold manufacturers are continually embracing technological advancements. High-speed machining, 3D printing for rapid prototyping, and sophisticated mold cooling systems are just a few examples of how technology is transforming the industry. These innovations not only improve efficiency but also reduce lead times and costs. Quality Control and Testing Quality control is paramount in injection mold manufacturing. Rigorous testing ensures that molds meet specifications and can produce flawless parts. Advanced metrology tools, such as coordinate measuring machines (CMMs), laser scanners, and X-ray inspection systems, are employed to guarantee precision and reliability. Environmental Responsibility In today’s environmentally conscious world, injection mold manufacturers are increasingly adopting sustainable practices. They focus on reducing material waste, energy consumption, and emissions. Additionally, many manufacturers explore bio-based and recyclable materials for mold production to minimize their carbon footprint. Global Reach Injection mold manufacturers have a global presence, serving industries worldwide. Whether it’s automotive components in Germany, consumer electronics in Japan, or medical devices in the United States, these manufacturers are instrumental in shaping diverse sectors of the economy. The Future of Injection Molding The future holds exciting possibilities for injection mold manufacturers. Industry 4.0 concepts, including the Internet of Things (IoT) and artificial intelligence (AI), are being integrated to create smart and predictive manufacturing environments. This not only enhances efficiency but also reduces downtime and maintenance costs. In conclusion, injection mold manufacturers are the unsung heroes behind the scenes, shaping the world of manufacturing. Their dedication to precision, craftsmanship, and innovation ensures that the products we rely on daily are of the highest quality. As technology advances and sustainability becomes increasingly important, the role of injection mold manufacturers will continue to evolve, pushing the boundaries of what is possible in the manufacturing world.