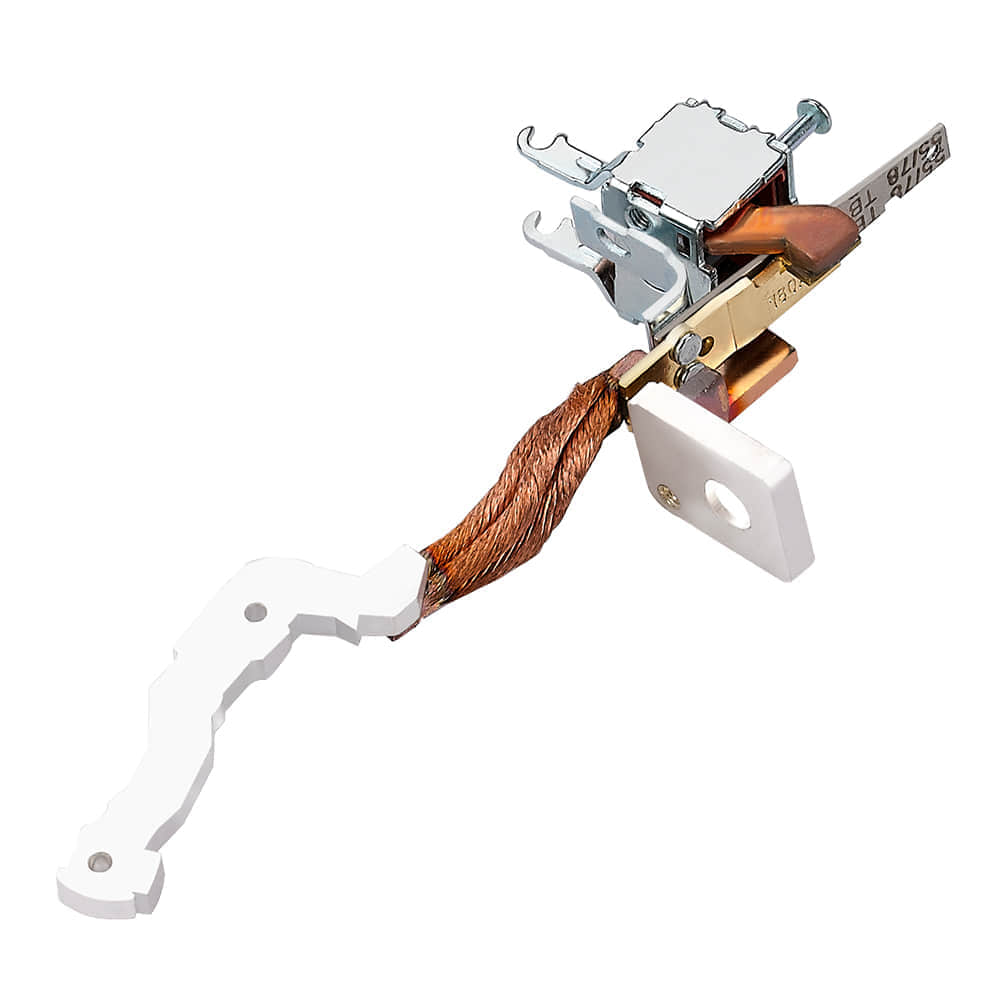

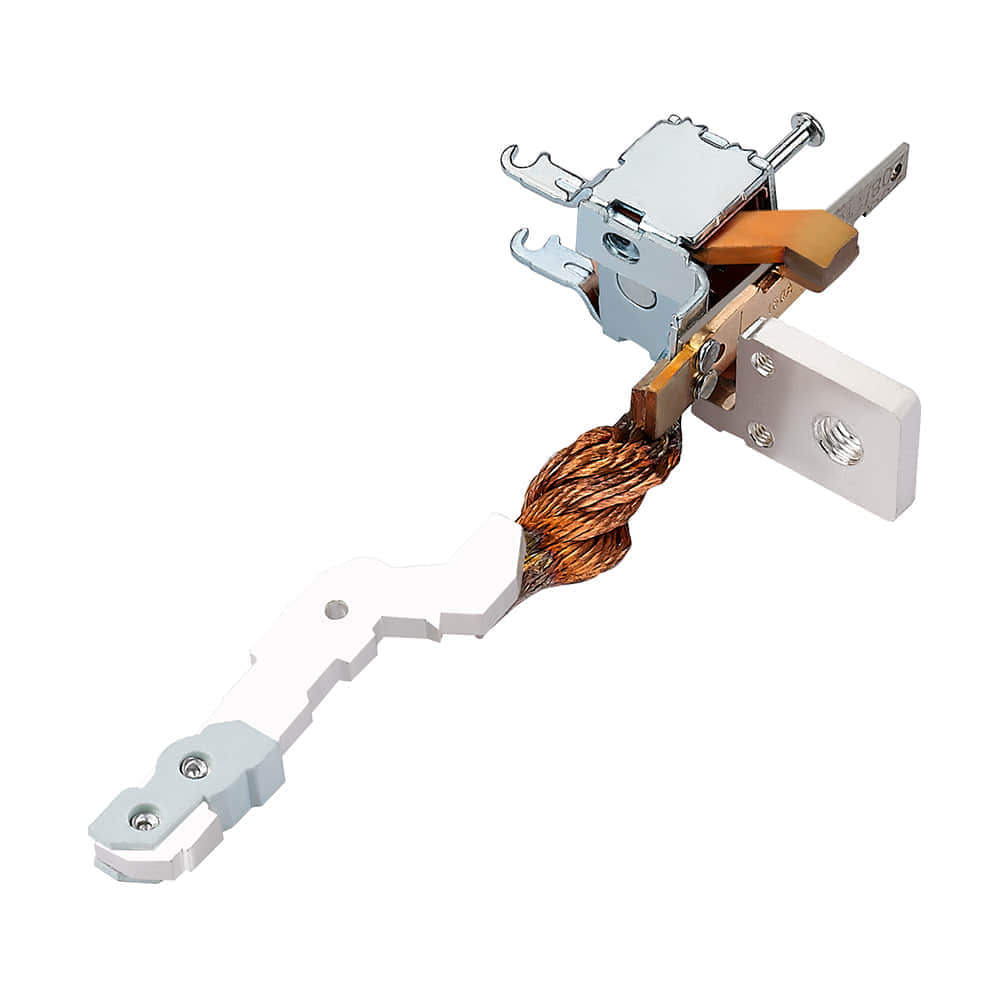

Metal stamping parts play a crucial role in a wide array of industries, from automotive manufacturing to electronics production. These precision-engineered components are manufactured through a process that combines artistry with technology, resulting in intricate pieces that drive innovation across sectors. In this article, we delve into the realm of metal stamping parts, uncovering their significance, manufacturing process, and diverse applications.

The Significance of Metal Stamping Parts

Metal stamping is a manufacturing technique that transforms flat metal sheets into various shapes, sizes, and configurations. The resulting metal stamping parts find applications in industries such as aerospace, telecommunications, medical equipment, and beyond. From tiny components like connectors to larger parts such as panels, the precision and consistency achieved in metal stamping are paramount. The Metal Stamping Process Metal stamping involves a series of steps, each executed with meticulous precision to ensure the final product’s quality and accuracy. The process typically includes: Design and Tooling:Engineers create detailed designs, which are then used to manufacture specialized tooling. These tools, including dies and punches, determine the shape and features of the stamped parts. Material Selection:The choice of metal is crucial, as it influences the part’s characteristics. Metals like steel, aluminum, and copper are commonly used due to their durability and malleability. Feeding:Metal sheets are fed into the stamping press. The press uses immense force to push the metal through the tooling, shaping it according to the design. Stamping:The metal is subjected to a combination of pressure, bending, and forming actions. These actions are precisely controlled by the tooling to create the desired shape. Trimming and Finishing:Excess metal, known as “flash,” is trimmed off, and additional finishing processes like deburring and coating may be applied to achieve the desired appearance and functionality. Quality Control:Stringent quality checks are performed to ensure that each part meets the required specifications. Any deviations or defects are addressed promptly. Diverse Applications The versatility of metal stamping parts is showcased by their applications in various industries: Automotive:Metal stamping produces intricate components used in engines, transmissions, and chassis, contributing to the overall performance and safety of vehicles. Electronics:In the electronics industry, metal stamping parts are used in connectors, casings, and heat sinks, ensuring proper functioning and heat dissipation. Aerospace:Precision is paramount in aerospace, where metal stamping contributes to manufacturing aircraft components that are lightweight yet structurally sound. Medical:Medical devices rely on metal stamping for components that require high precision, biocompatibility, and reliability. Renewable Energy:The solar and wind energy sectors utilize metal stamping in the production of parts for panels, turbines, and energy storage systems. Advantages of Metal Stamping Metal stamping offers several advantages that contribute to its widespread use: Cost-Efficiency:Mass production capabilities and minimal material wastage make metal stamping a cost-effective option for large-scale manufacturing. Precision and Consistency:The use of precision tooling ensures uniformity and accuracy across a production run. Speed:Metal stamping processes are relatively quick, enabling efficient production rates to meet demand. Complexity:Intricate designs can be achieved through multiple stamping actions, allowing for complex shapes and features. Conclusion The world of metal stamping parts is a testament to human ingenuity and engineering prowess. From the design phase to the final quality checks, every step in the process contributes to the creation of components that are the backbone of modern industries. As technology continues to advance, metal stamping is poised to further revolutionize manufacturing, enabling the production of increasingly intricate and efficient parts that drive innovation forward.