In today’s rapidly evolving industrial landscape, injection molded parts have emerged as essential components in a wide array of products, ranging from consumer electronics to medical devices. At the heart of this revolution lies the Injection Molded Parts Manufacturer, a key player in turning imaginative designs into tangible realities with precision, efficiency, and innovation.

Precision Engineering: Mastering the Art of Perfection

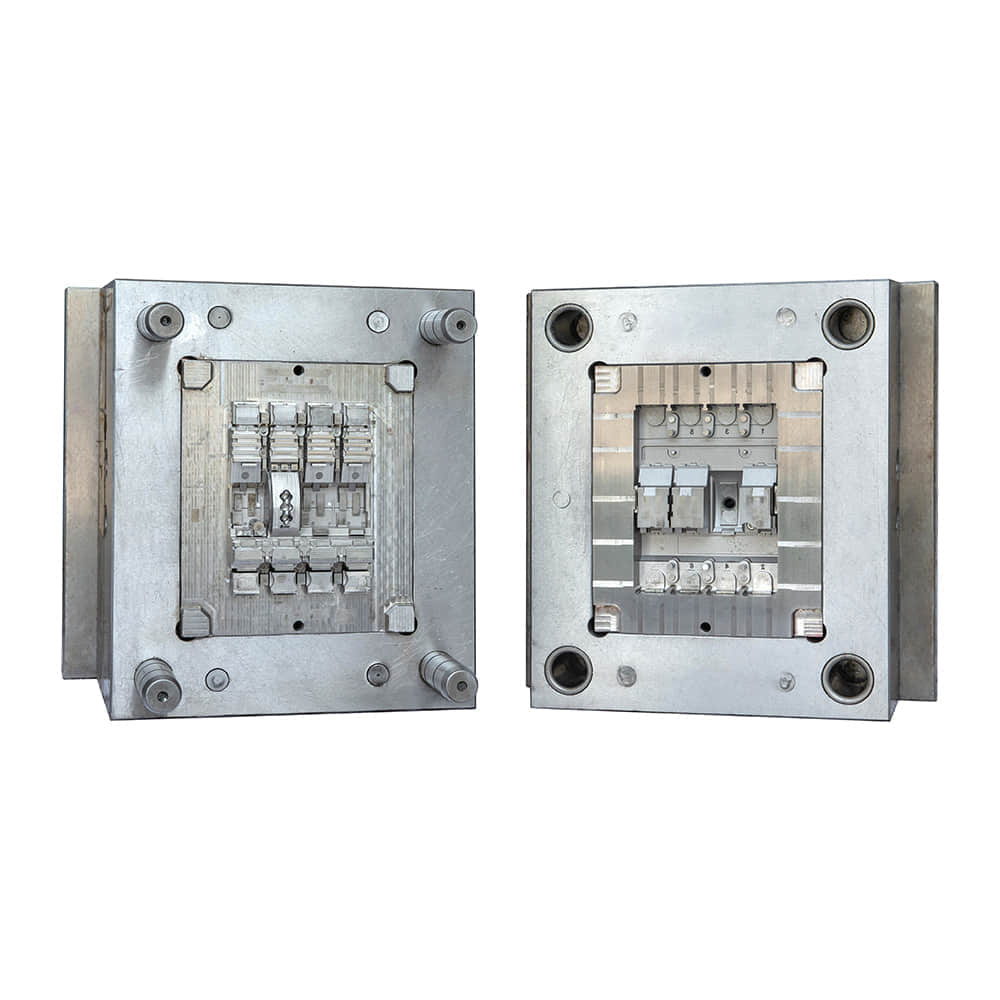

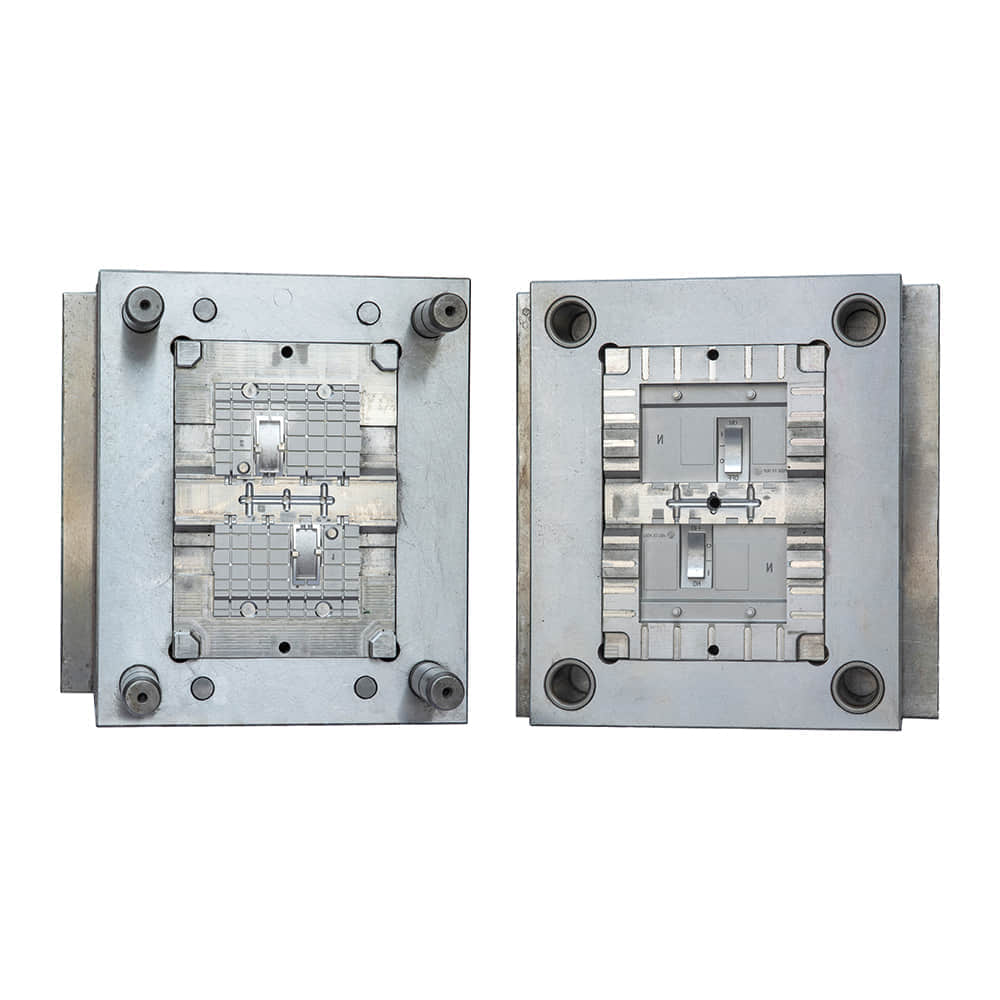

Injection molding is a manufacturing process that involves injecting molten material, usually plastic, into a mold cavity. This process requires a delicate balance of design expertise, engineering prowess, and cutting-edge technology. Injection molded parts manufacturers specialize in achieving precision in every step, from the initial design and mold creation to the final production. The journey begins with design. Manufacturers collaborate closely with clients to conceptualize and refine product designs. Computer-aided design (CAD) software helps in translating these ideas into digital models. These virtual representations allow for meticulous analysis and adjustments before physical production commences. Innovation at the Core In the world of injection molded parts, innovation is not just a buzzword – it’s a driving force. Manufacturers constantly push the boundaries of what’s possible. They experiment with new materials, advanced molding techniques, and sustainable practices. One area witnessing rapid innovation is material selection. Manufacturers are exploring biodegradable and recycled materials to create environmentally friendly products without compromising on quality. Moreover, they’re experimenting with composite materials to enhance the mechanical and thermal properties of the molded parts, opening doors to even wider applications. Efficiency: Optimizing Production Processes Efficiency is paramount in modern manufacturing, and injection molded parts manufacturers excel in optimizing their production processes. With automated systems and robotics, they ensure consistency, reduce human errors, and accelerate production rates. This not only streamlines the manufacturing process but also enhances the overall quality of the parts produced. Furthermore, manufacturers implement lean manufacturing principles to minimize waste and improve resource utilization. This approach benefits both the company’s bottom line and the environment. Quality Control: Ensuring Excellence Maintaining high-quality standards is non-negotiable in injection molded parts manufacturing. Manufacturers employ a range of quality control measures to ensure that each piece meets specifications. Advanced imaging technologies, such as X-ray and laser scanning, are used to identify even the slightest defects that might not be visible to the naked eye. The Human Factor: Skilled Craftsmanship in a High-Tech World While technology plays a pivotal role, skilled human intervention remains irreplaceable. Engineers, designers, and technicians bring their expertise to the table, fine-tuning processes, troubleshooting issues, and making critical decisions that machines cannot replicate. It’s the synergy between human craftsmanship and technological innovation that yields exceptional results. Applications Across Industries The influence of injection molded parts manufacturers extends across industries. In the automotive sector, they contribute to lightweight yet durable components that enhance fuel efficiency. Medical devices owe their precision and reliability to meticulously manufactured injection molded parts. Consumer electronics benefit from intricate designs that accommodate advanced functionalities. A Sustainable Future As the world embraces sustainability, injection molded parts manufacturers are actively contributing to eco-friendly practices. By embracing bioplastics, recycling programs, and energy-efficient processes, they’re minimizing their carbon footprint and setting an example for other industries. Conclusion The realm of injection molded parts manufacturing is one of precision, innovation, and collaboration. Manufacturers play a vital role in shaping the products that define modern life. With an unwavering commitment to excellence and a forward-looking approach, they continue to drive progress, redefine possibilities, and transform ideas into reality.