In the world of manufacturing, precision and efficiency are paramount. Industries ranging from automotive to electronics rely on metal stamping to create intricate components with impeccable accuracy. Behind the scenes, Metal Stamping Die OEM Manufacturers play a pivotal role in enabling this precision. In this article, we will delve into the essential functions of these manufacturers and their impact on various industries.

I. The Foundation: Metal Stamping Die OEM Manufacturers

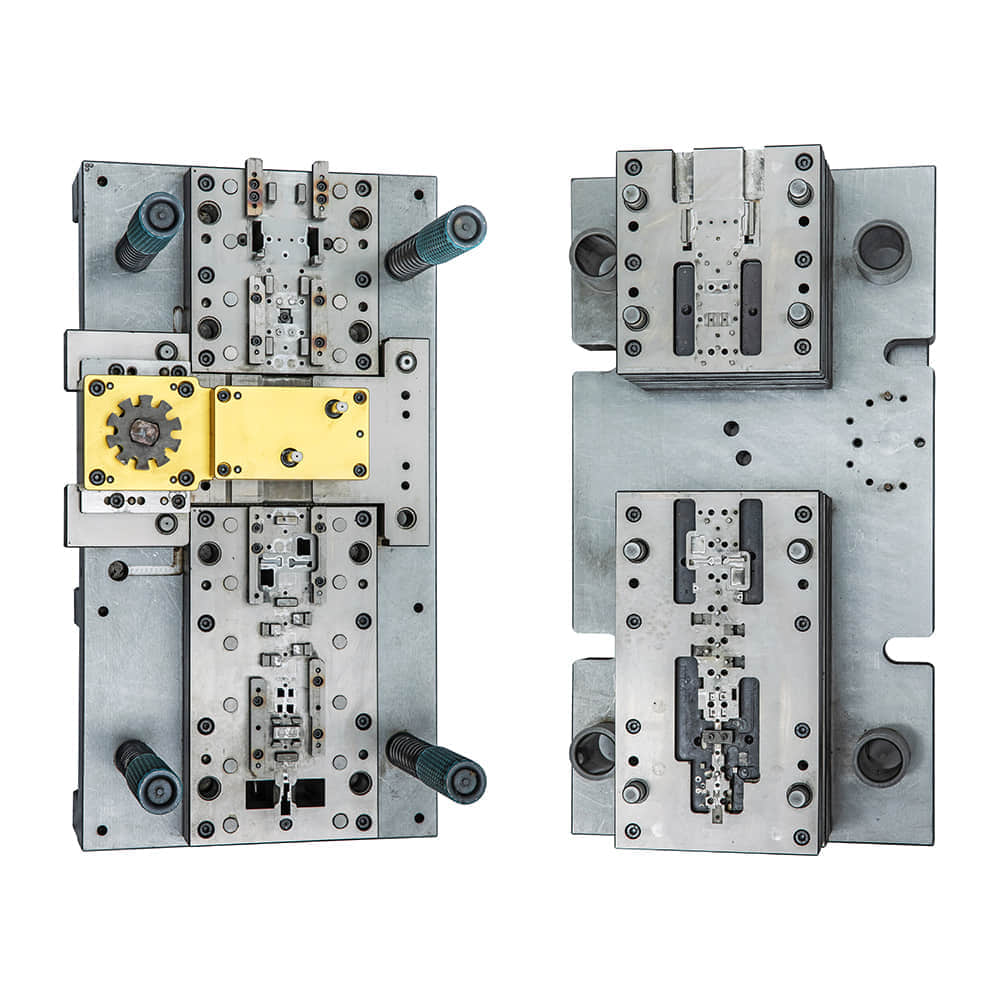

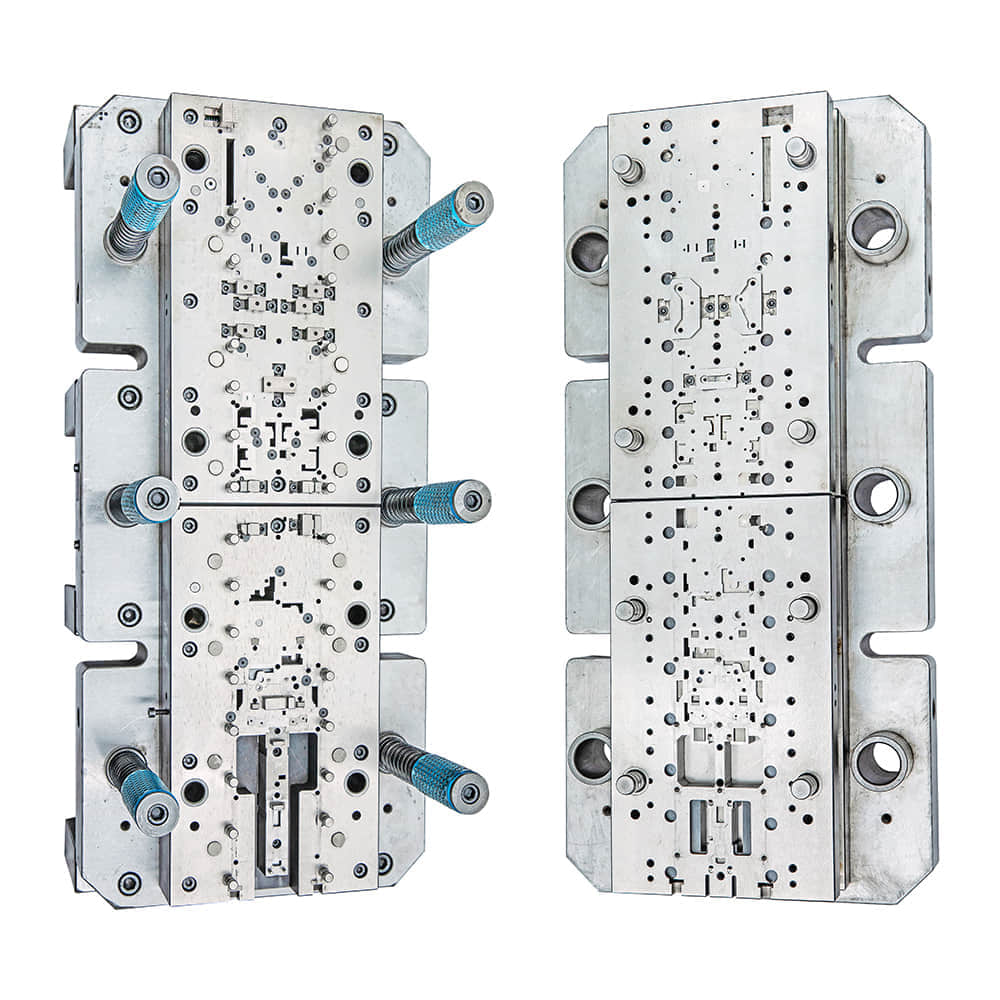

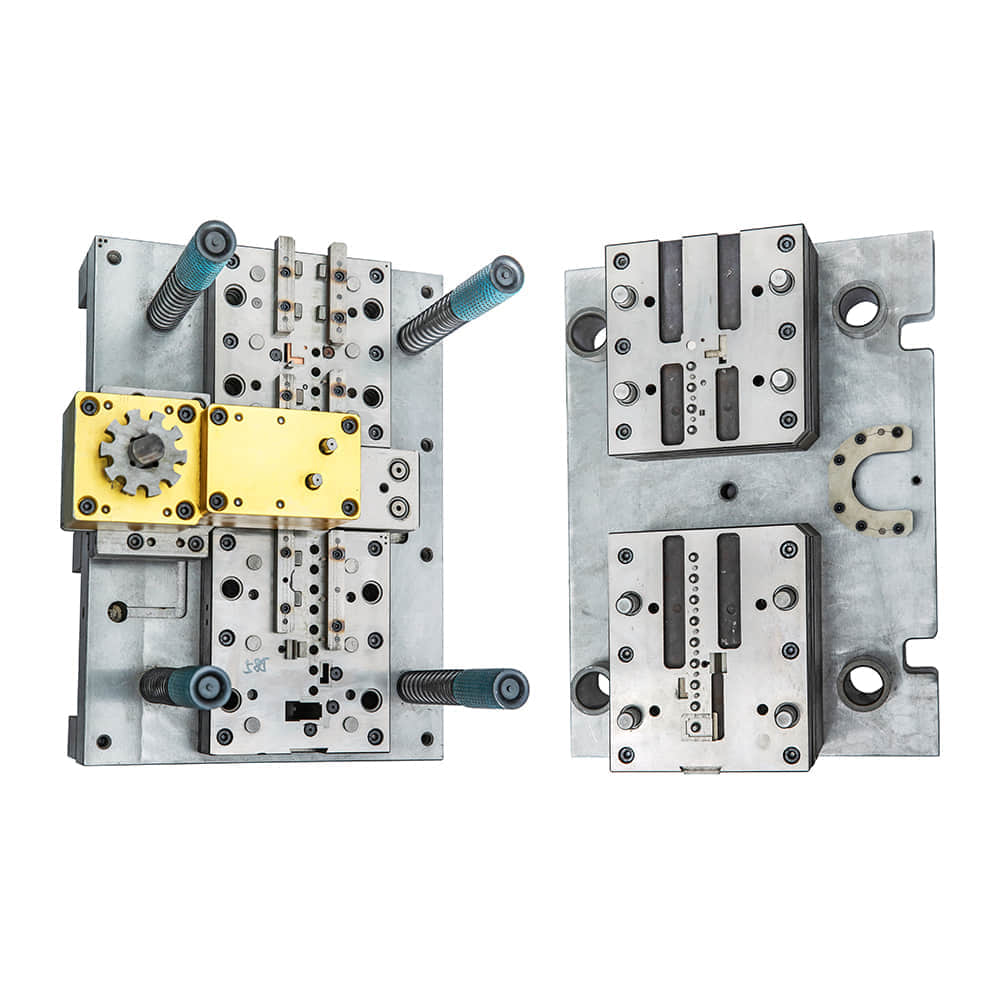

Metal Stamping Die OEM Manufacturers serve as the backbone of metal stamping processes. They are responsible for designing, fabricating, and maintaining the dies used in the stamping machines. These dies are intricate tools that determine the shape and size of the stamped metal parts. They are, in essence, the molds used in the metal stamping process. II. Design Expertise One of the primary responsibilities of Metal Stamping Die OEM Manufacturers is to create precise and intricate die designs. This demands a deep understanding of engineering principles, materials science, and metallurgy. The design process involves CAD (Computer-Aided Design) software and meticulous calculations to ensure that the dies will produce parts that meet strict quality standards. III. Material Selection Choosing the right materials for stamping dies is crucial. OEM manufacturers must consider factors such as the type of metal being stamped, production volume, and desired lifespan of the dies. Materials like tool steel, carbide, and high-speed steel are commonly used due to their durability and wear resistance. IV. Precision Machining Once the design and materials are chosen, Metal Stamping Die OEM Manufacturers employ precision machining techniques to create the dies. This step requires high-precision equipment, such as CNC (Computer Numerical Control) machines, to ensure that the dies are manufactured to exact specifications. V. Quality Control Quality control is a non-negotiable aspect of die manufacturing. OEM Manufacturers employ rigorous inspection processes to guarantee that the dies meet the required tolerances and specifications. This includes testing for dimensional accuracy, hardness, and durability. VI. Versatility Across Industries Metal Stamping Die OEM Manufacturers cater to a diverse range of industries. From automotive manufacturers producing intricate engine components to electronics companies crafting microchips, the versatility of these manufacturers is evident. Their ability to adapt and create specialized dies for various applications underscores their importance. VII. Collaborative Innovation Innovation is at the heart of Metal Stamping Die OEM Manufacturing. These manufacturers often collaborate closely with their clients to develop innovative solutions. Whether it’s finding ways to reduce production costs or enhancing the quality of stamped parts, OEM manufacturers are key partners in the pursuit of progress. VIII. Efficiency and Cost Reduction Efficiency is paramount in modern manufacturing. Metal Stamping Die OEM Manufacturers contribute to this by designing dies that optimize material usage and reduce waste. They also play a significant role in reducing overall production costs by extending the lifespan of dies through maintenance and refurbishment. IX. Environmental Responsibility Sustainability is a growing concern in manufacturing. Metal Stamping Die OEM Manufacturers are increasingly incorporating environmentally friendly practices into their operations. This includes the use of recycled materials for die manufacturing and implementing energy-efficient processes. X. Conclusion: The Unseen Heroes of Precision In the world of manufacturing, Metal Stamping Die OEM Manufacturers may operate behind the scenes, but their role is indispensable. They are the architects of precision, the guardians of quality, and the enablers of progress. Their commitment to innovation and efficiency ensures that industries around the world can continue to produce high-quality, precise components that power our modern lives. In conclusion, the work of Metal Stamping Die OEM Manufacturers is a testament to the fusion of craftsmanship and technology, where precision is the common language spoken across industries. Their silent dedication ensures that the products we use daily meet the highest standards of quality and reliability.