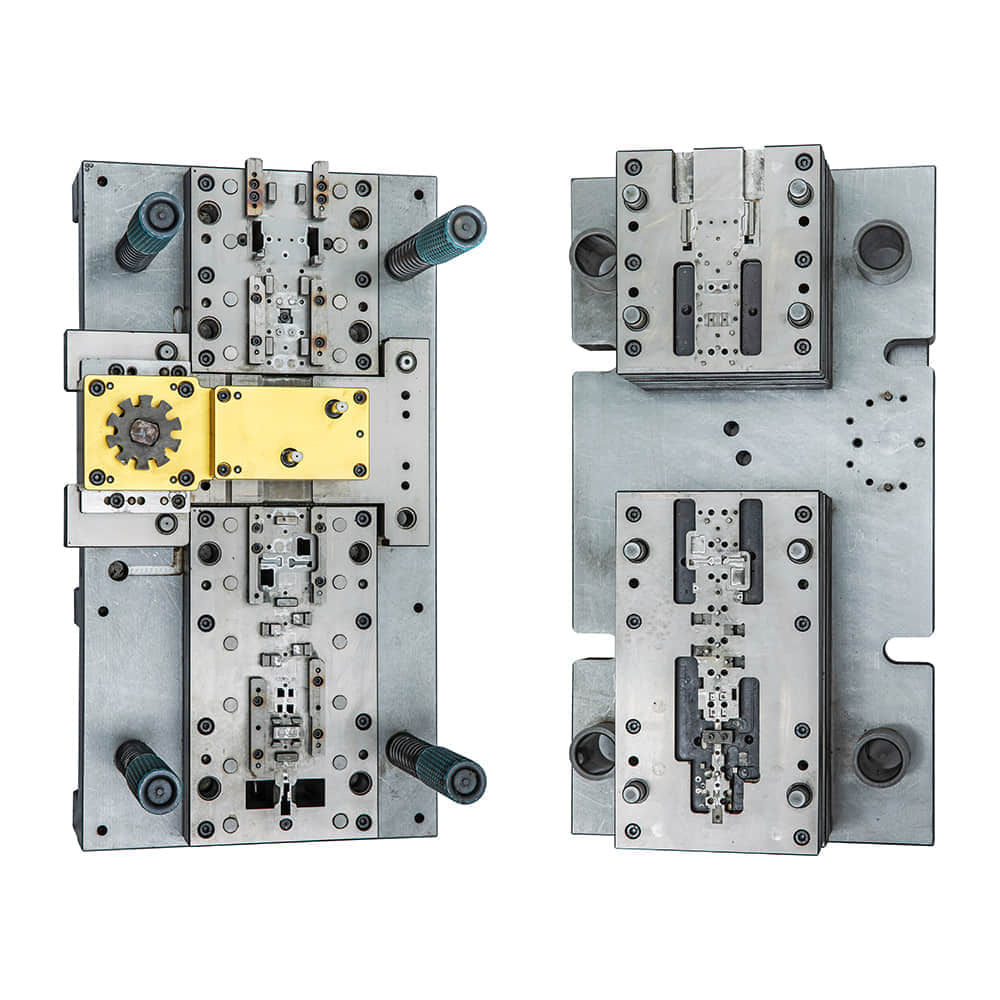

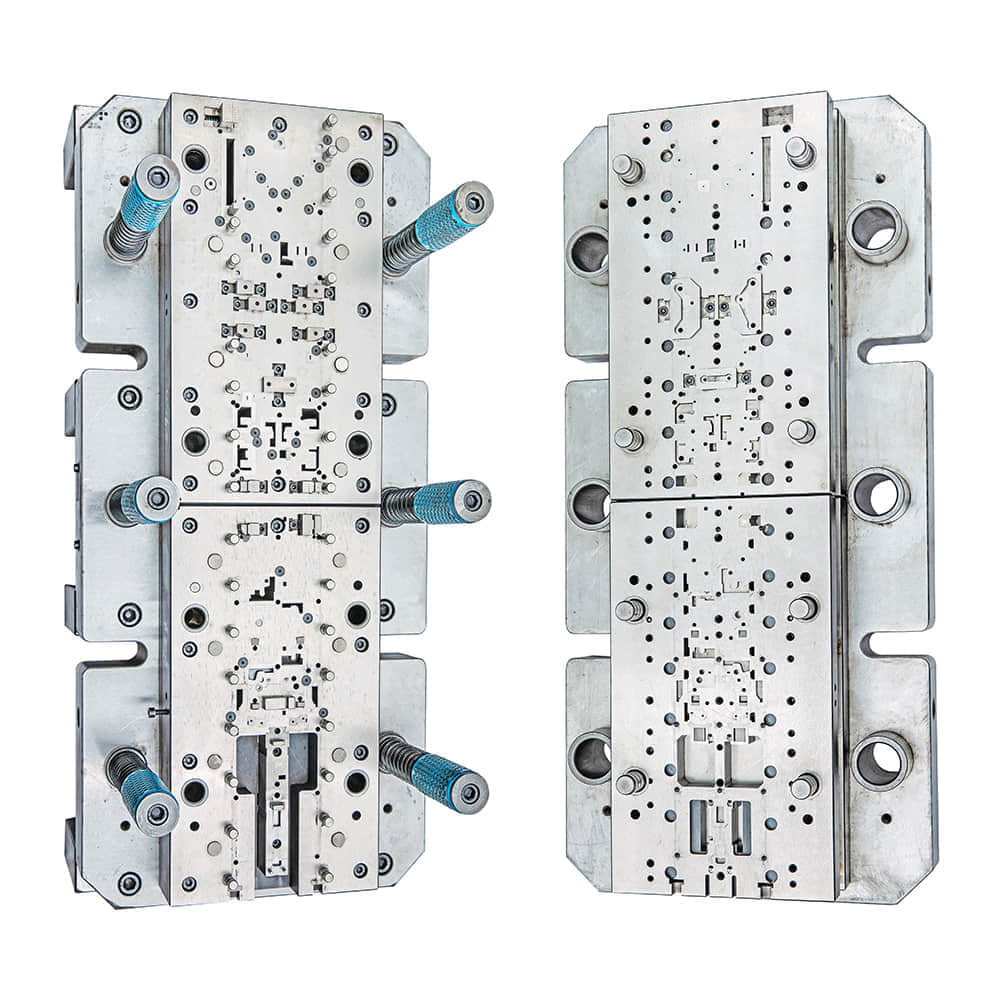

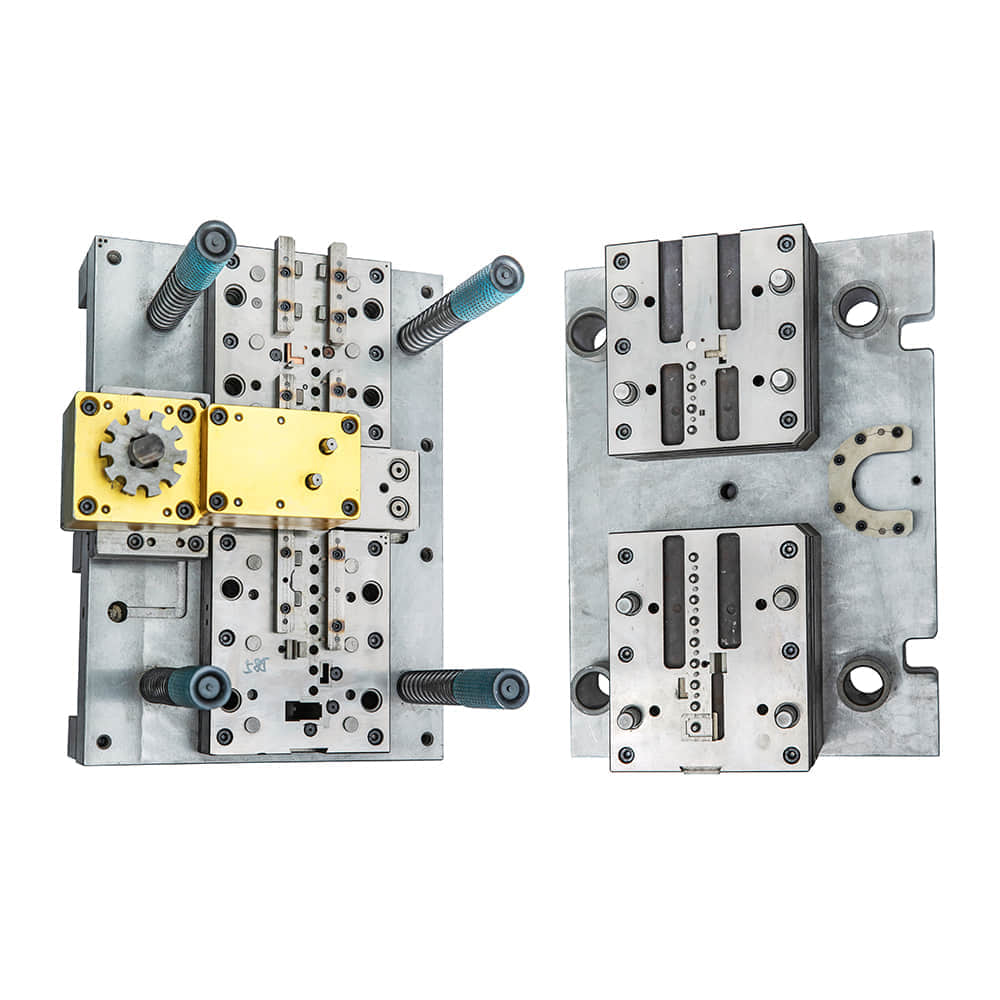

In the realm of modern manufacturing, metal stamping dies play an indispensable role in shaping metal components with accuracy and efficiency. A key player in this process is the metal stamping die manufacturer – a specialized craftsman of tools that define the intricate contours and designs of countless products we encounter in our daily lives.

Metal stamping die manufacturers are the unsung heroes behind the scenes, employing their expertise to produce dies that are essential in industries ranging from automotive and aerospace to electronics and consumer goods. These experts combine innovation, engineering, and skilled craftsmanship to create tools that form the foundation of mass production.

At the heart of metal stamping die manufacturing lies a blend of cutting-edge technology and time-honored craftsmanship. Computer-Aided Design (CAD) software is utilized to conceptualize intricate designs with precision measurements. These designs are then transformed into reality through a meticulous process that involves CNC machining, heat treatment, and meticulous assembly. The outcome is a robust stamping die capable of withstanding immense pressures while consistently producing uniform parts. Innovation is a hallmark of the metal stamping die manufacturing industry. Manufacturers are continually pushing the boundaries of what is possible, developing new techniques and materials to enhance the durability and performance of their dies. Advanced coatings and surface treatments are applied to prevent wear and prolong the lifespan of the dies, resulting in a lower production cost per part over time. Beyond the technological advancements, the role of craftsmanship in this field remains pivotal. Experienced engineers and toolmakers bring their skill and insight to every step of the process. Their keen attention to detail ensures that the dies produced are not only technically sound but also finely tuned to achieve the desired outcome. This level of expertise is particularly critical when creating dies for complex shapes and intricate patterns, where even the slightest deviation can lead to defective parts. Collaboration is another key aspect of the metal stamping die manufacturing process. Manufacturers work closely with clients to understand their specific needs and requirements. Whether it’s a delicate medical device component or a robust automotive part, the manufacturer’s ability to translate these demands into a functional die speaks to their adaptability and problem-solving skills. This collaborative approach often results in custom-designed dies that maximize efficiency and minimize waste during production. Quality control is paramount in metal stamping die manufacturing. Rigorous testing and validation processes ensure that the dies meet the highest standards before they’re put into production. This commitment to quality not only reflects the manufacturer’s dedication to their craft but also safeguards the reputation of the industries relying on these dies to create reliable end products. In conclusion, metal stamping die manufacturers are the backbone of modern manufacturing, enabling the mass production of intricate metal components that populate our world. Their blend of innovative technologies, traditional craftsmanship, and dedication to quality underscores their crucial role in various industries. As technology continues to evolve, one thing remains certain: the expertise and precision of metal stamping die manufacturers will continue to shape the way we produce and interact with the products around us.