In the realm of modern manufacturing, precision and efficiency are paramount. Among the many techniques and technologies that drive industries forward, metal stamping stands out as a cornerstone of mass production. At the heart of this process lies the metal stamping die – a crucial tool that shapes raw materials into intricate components with accuracy and repeatability. Let’s delve into the world of metal stamping die manufacturers, where innovation and expertise converge to shape the future of manufacturing.

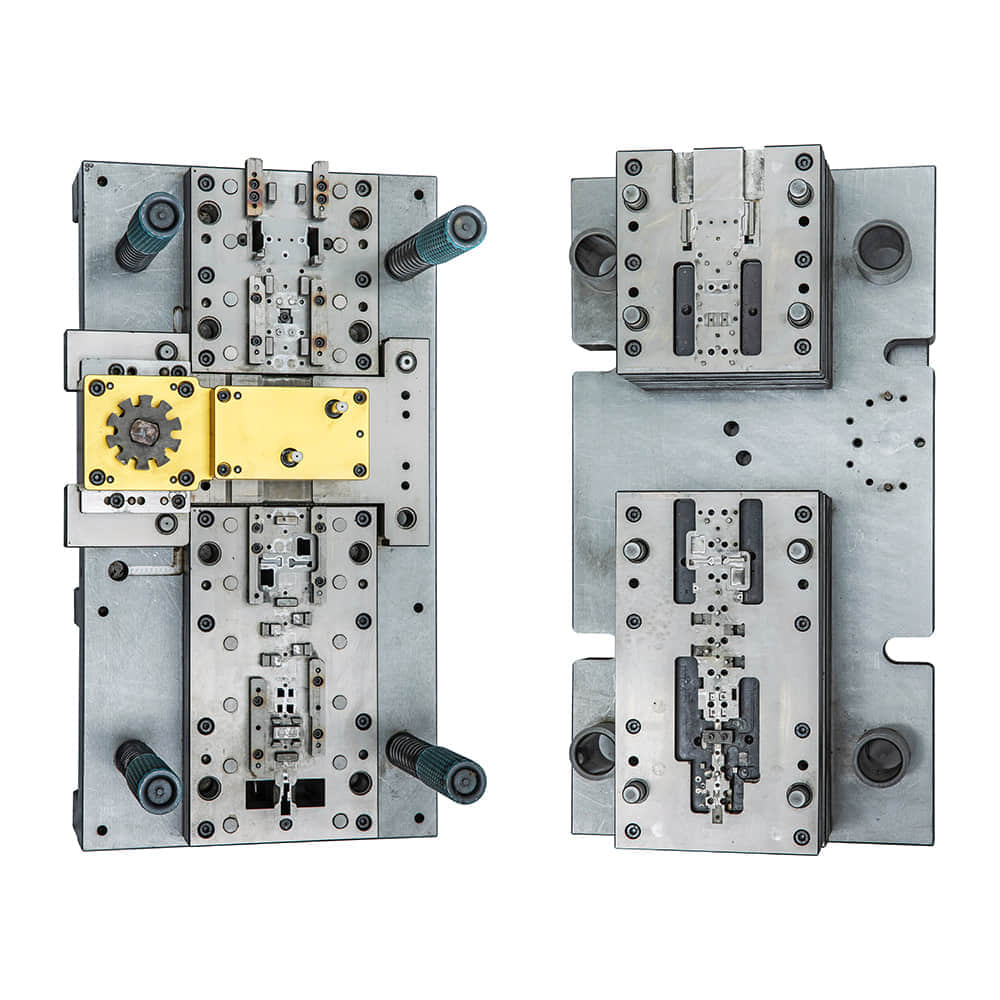

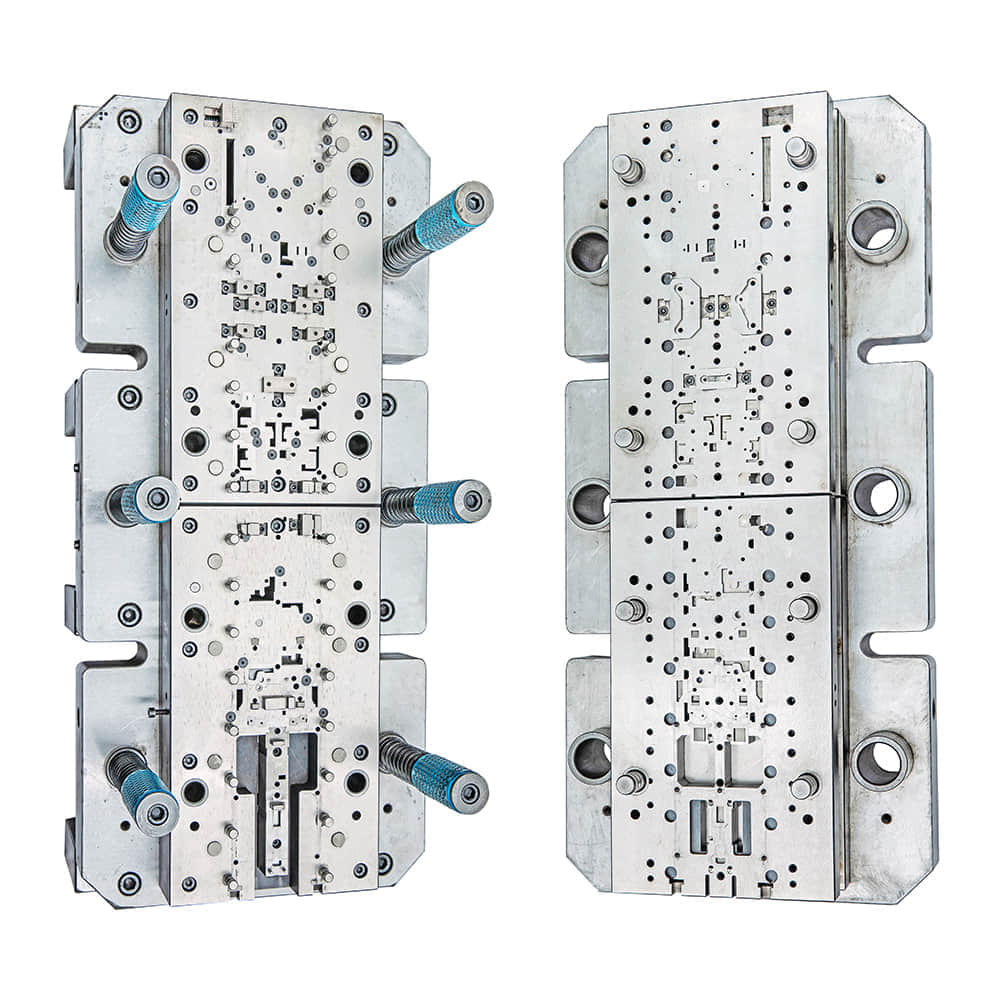

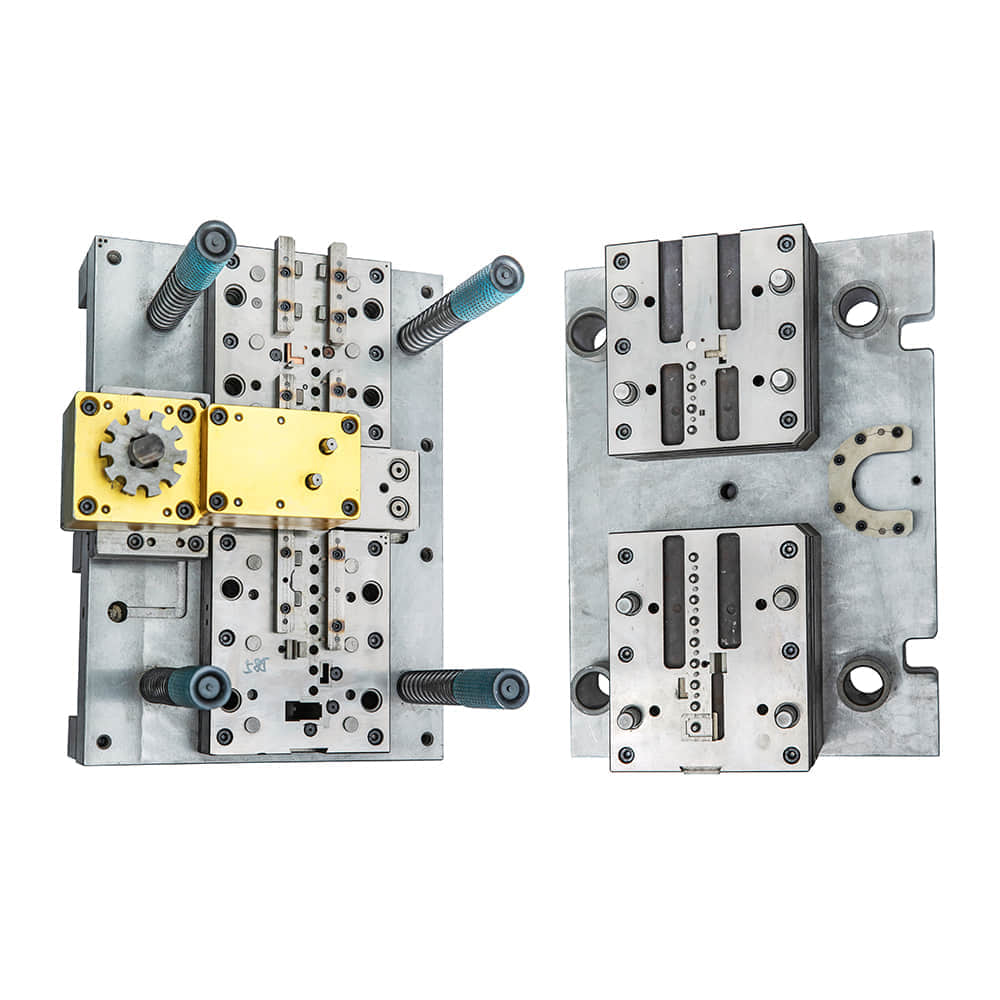

A metal stamping die is more than just a tool; it’s a product of meticulous engineering and craftsmanship. These dies are used to shape, cut, or form metal sheets into desired shapes with incredible consistency. From the automotive sector to electronics, metal stamped parts are integral to various industries. Behind the scenes, skilled manufacturers play a pivotal role in designing and producing these essential tools.

The process of manufacturing metal stamping dies begins with meticulous planning and design. Experienced engineers collaborate with clients to understand their specific needs, considering factors like material properties, part dimensions, and production volume. Advanced computer-aided design (CAD) software is employed to create intricate die designs with precision down to micrometers. Once the design is finalized, the manufacturing process kicks off. High-quality tool and die steels are chosen for their durability and heat resistance. Manufacturers employ cutting-edge machining techniques, such as computer numerical control (CNC) milling, electrical discharge machining (EDM), and wire EDM, to shape the steel into the die’s components. These methods ensure that even the tiniest details are accurately replicated on the die. The expertise of metal stamping die manufacturers shines through during the assembly and finishing stages. Every component must fit seamlessly to ensure optimal performance. The assembly process demands a blend of technical proficiency and a keen eye for detail. Manufacturers meticulously examine the die’s components, making any necessary adjustments to guarantee flawless operation. Surface finishing is another critical step. Techniques like grinding, polishing, and heat treatment are applied to enhance the die’s durability and precision. The end result is a meticulously crafted tool that’s ready to perform its magic in the metal stamping process. Innovation is a driving force in the metal stamping die manufacturing industry. As new materials and technologies emerge, manufacturers strive to push the boundaries of what’s possible. Advanced simulation software allows engineers to predict how dies will perform before they’re even produced, reducing lead times and minimizing errors. Additionally, the integration of Internet of Things (IoT) devices and sensors into dies enables real-time monitoring of performance, leading to predictive maintenance and improved efficiency. Quality control remains a cornerstone of metal stamping die manufacturing. Rigorous testing procedures are in place to ensure that each die meets exacting standards. Dimensional accuracy, surface finish, and durability are scrutinized to guarantee that the end product aligns with the client’s requirements. In conclusion, the world of metal stamping die manufacturers is one of precision craftsmanship and innovative technologies. These manufacturers play an indispensable role in shaping industries by providing the tools that facilitate mass production with unparalleled accuracy. From initial design to final assembly, their expertise ensures that the heart of metal stamping – the die – performs seamlessly, ultimately driving progress across various sectors.