In the world of manufacturing, precision and quality are paramount. Metal stamping parts manufacturers play a pivotal role in various industries by producing intricate components that are essential for countless products. In this article, we will delve into the fascinating realm of metal stamping, uncovering the processes, technologies, and innovations that drive this industry.

The Art of Metal Stamping

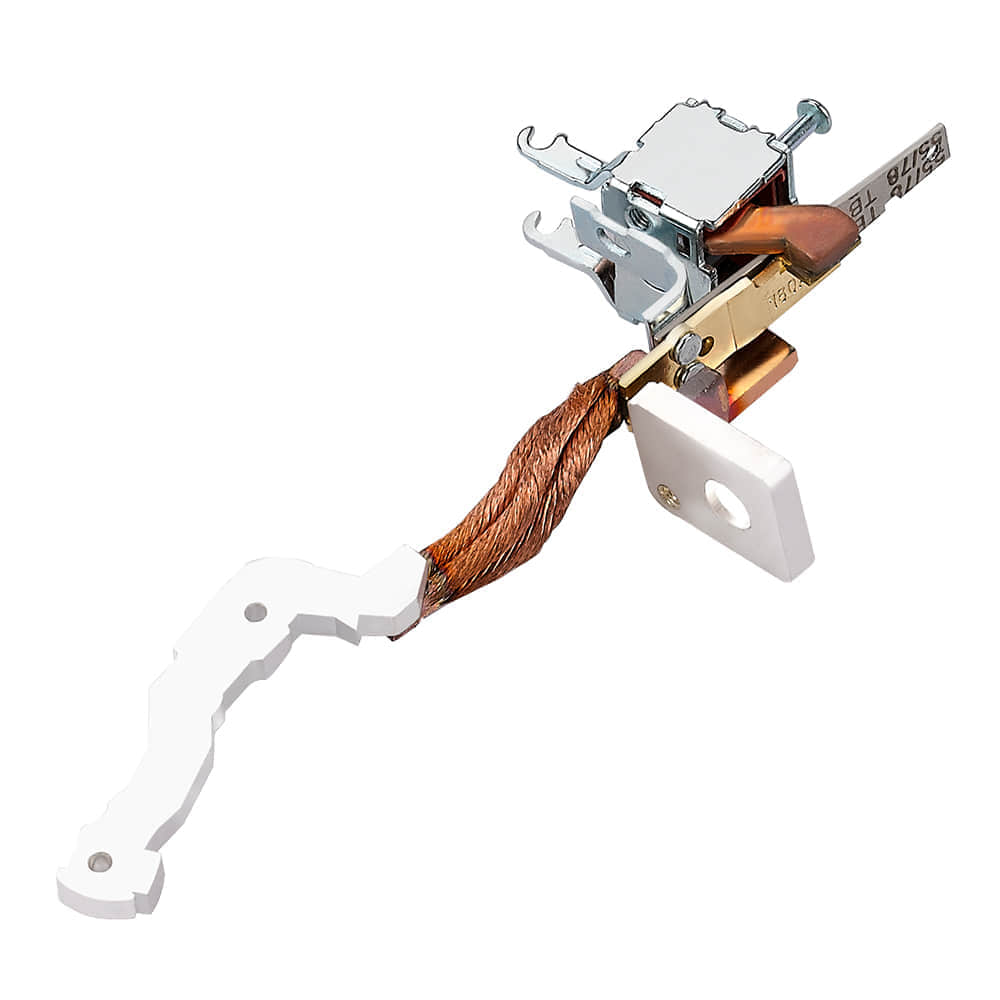

Metal stamping is a manufacturing process that involves shaping metal sheets into desired forms and sizes. This method is widely employed to create components used in automotive, aerospace, electronics, and appliance industries, among others. The key to metal stamping’s success lies in its ability to produce high-precision parts with efficiency and cost-effectiveness. Materials Matter The quality of metal stamping parts hinges on the materials used. Manufacturers work with various metals, including steel, aluminum, copper, and alloys, selecting the most appropriate material for the specific application. This careful material selection ensures that the end product meets the required strength, durability, and corrosion resistance criteria. The Stamping Process Metal stamping is a multi-step process that demands precision at every stage: Design and Tooling: It all begins with a well-thought-out design and the creation of specialized stamping tools, such as dies and molds. These tools are essential for shaping the metal accurately. Material Preparation: The selected metal is cut into sheets of the appropriate size and thickness, ready for the stamping process. Stamping: The metal sheet is placed into a stamping press, where it is subjected to immense pressure. The dies and molds shape the metal into the desired form, with computer-controlled precision. Trimming and Secondary Operations: After stamping, the parts may undergo trimming, deburring, welding, or other secondary operations to refine their finish. Quality Control: Stringent quality control measures are implemented to ensure that every part meets the specified standards. Technological Advancements Advancements in technology have revolutionized the metal stamping industry. Computer Numerical Control (CNC) machines and robotics have improved precision and efficiency. 3D printing is also finding its place in metal stamping, allowing for rapid prototyping and customization. Environmental Responsibility Metal stamping manufacturers are increasingly conscious of their environmental footprint. Sustainable practices, such as recycling scrap metal and reducing energy consumption, are becoming standard. By adopting greener initiatives, these manufacturers contribute to a more eco-friendly manufacturing landscape. Customization and Innovation As industries evolve, so do their demands for metal stamping parts. Manufacturers have responded by offering customization options and innovative solutions. From intricate electrical connectors to complex automotive components, metal stamping manufacturers are continuously pushing the boundaries of what is possible. Global Reach Metal stamping parts manufacturers operate on a global scale. They serve industries worldwide, offering their expertise and products to companies seeking reliable and high-quality components. This global presence ensures that industries across borders can access the parts they need to thrive. Conclusion Metal stamping parts manufacturers are the unsung heroes of modern manufacturing. Their precision, dedication to quality, and commitment to innovation drive progress across a multitude of industries. As technology continues to advance and environmental awareness grows, we can expect even more exciting developments in the world of metal stamping. These manufacturers are poised to play a pivotal role in shaping the future of manufacturing, one stamped part at a time.