In the realm of modern manufacturing, metal stamping parts manufacturers play a pivotal yet often understated role. These specialized craftsmen and industries are the unsung heroes behind many of the everyday items we use, from automotive components to household appliances. In this article, we will delve into the fascinating world of metal stamping parts manufacturing, exploring its processes, significance, and innovations.

The Art of Metal Stamping

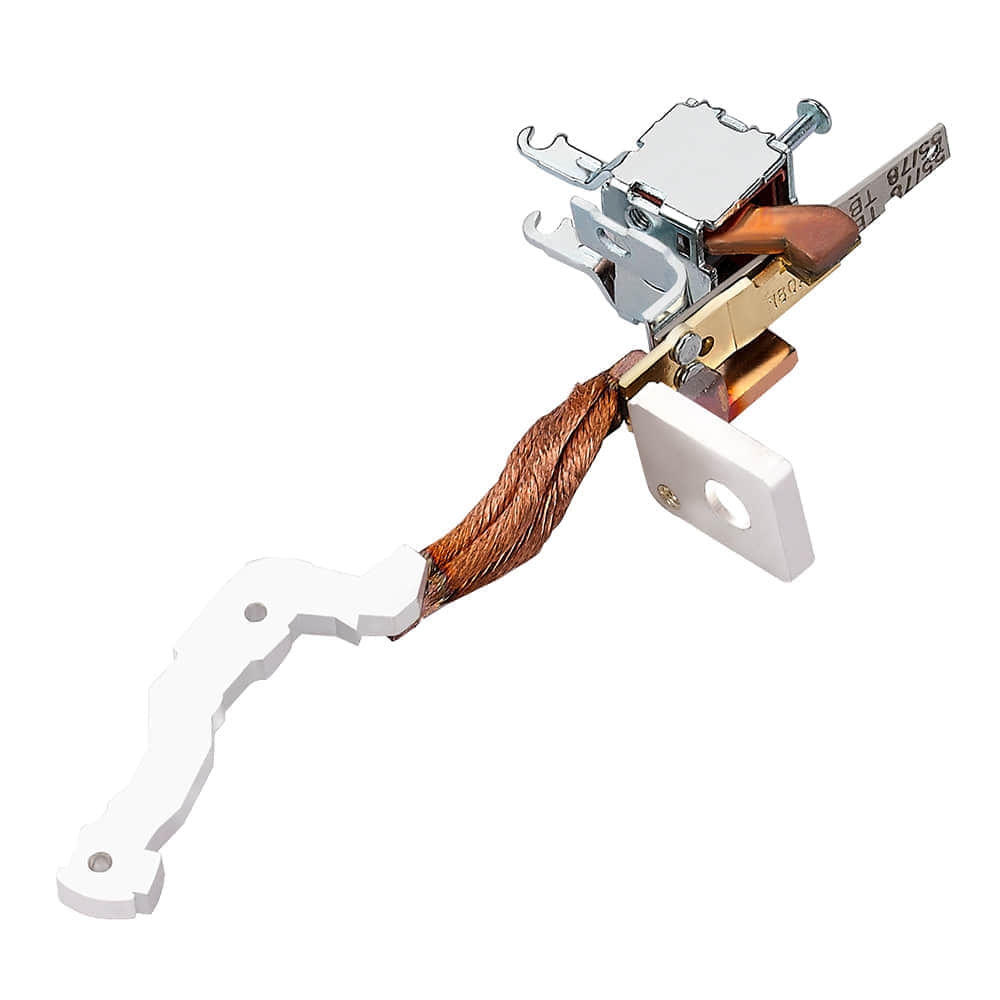

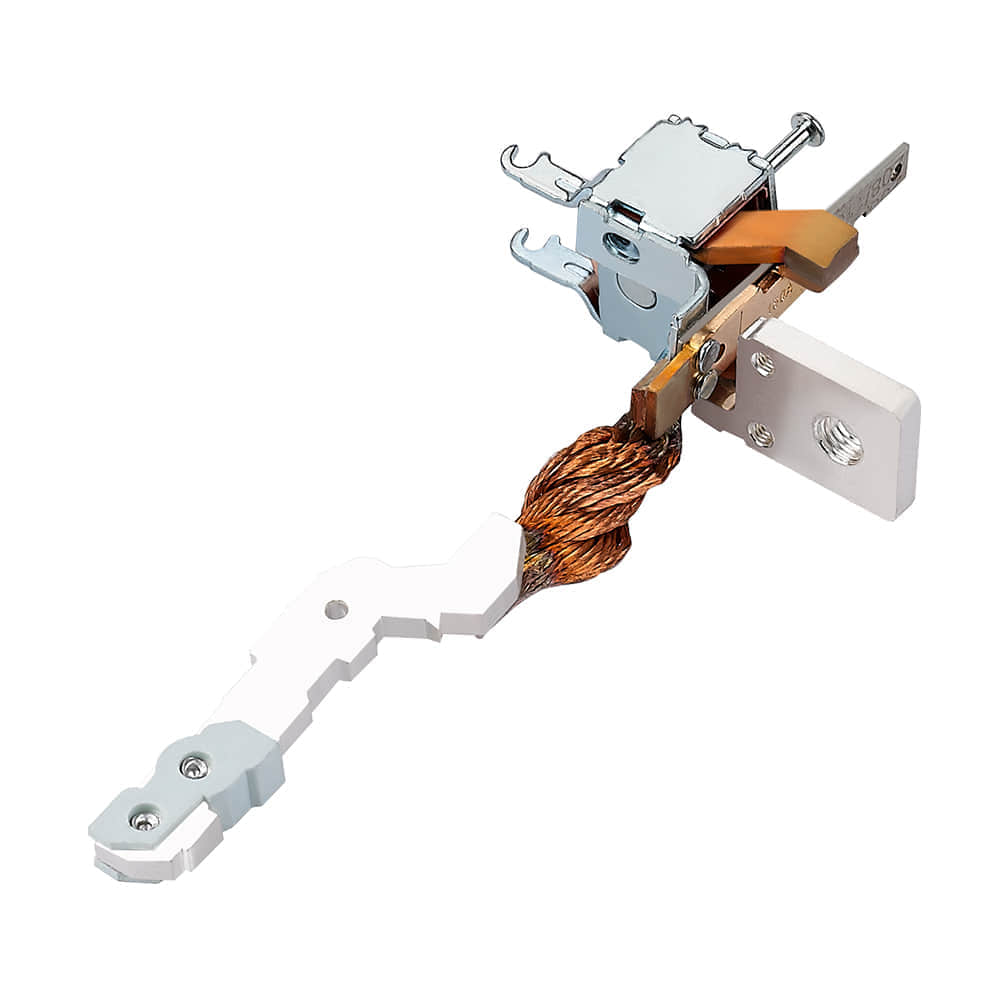

Metal stamping is a versatile and precise manufacturing process that involves shaping, cutting, and forming metal sheets or coils into desired components. These components can range from intricate electrical connectors to structural elements in aircraft. The process is known for its high precision, making it a preferred choice for industries that demand accuracy and consistency. Materials Matter Metal stamping manufacturers work with a variety of materials, including steel, aluminum, copper, and even exotic alloys. The choice of material depends on the specific requirements of the component. For instance, steel is favored for its strength and durability, while aluminum’s lightweight properties make it ideal for aerospace applications. The ability to adapt to diverse materials is a testament to the expertise of metal stamping manufacturers. Precision at its Core Precision is the cornerstone of metal stamping. Manufacturers employ computer-aided design (CAD) software and computer numerical control (CNC) machines to create intricate tooling and dies. These tools are custom-made for each component, ensuring that every piece produced is consistent and accurate to the micrometer. Applications Across Industries The versatility of metal stamping parts manufacturing is evident in its applications across various industries: Automotive Industry:Metal stamping is a linchpin of automobile manufacturing, producing components like body panels, brackets, and engine parts. These parts need to be both strong and lightweight, making metal stamping an ideal choice. Electronics:The miniaturization of electronic devices demands precision components. Metal stamping manufacturers supply connectors, heat sinks, and shielding components that are crucial for the functionality of smartphones, laptops, and other gadgets. Aerospace:Aerospace companies rely on metal stamping to create lightweight but robust components for aircraft and spacecraft, contributing to fuel efficiency and safety. Medical Devices:In the medical field, precision is a matter of life and death. Metal stamping manufacturers produce critical components for medical devices, such as surgical instruments and implantable devices. Innovation in Metal Stamping Metal stamping has evolved significantly over the years. Advancements in technology have led to faster production rates, reduced waste, and improved quality control. Additionally, the integration of automation and robotics has made the process more efficient, reducing labor costs and increasing output. Sustainability Matters In the era of environmental consciousness, metal stamping manufacturers are also making strides towards sustainability. Efforts are being made to reduce material waste, energy consumption, and harmful emissions. The use of recycled materials and lean manufacturing principles further demonstrates the commitment of the industry to sustainable practices. Conclusion Metal stamping parts manufacturers are the unsung heroes of modern manufacturing. Their precision craftsmanship underpins numerous industries, from automotive to aerospace and electronics. With a commitment to innovation and sustainability, they continue to shape the world around us, ensuring that the products we rely on every day are safe, reliable, and of the highest quality.