In the intricate world of manufacturing, where precision and efficiency are paramount, metal stamping parts manufacturers play a vital role. With their advanced techniques and cutting-edge technology, they contribute significantly to various industries by producing high-quality metal parts used in countless applications.

The Art of Metal Stamping

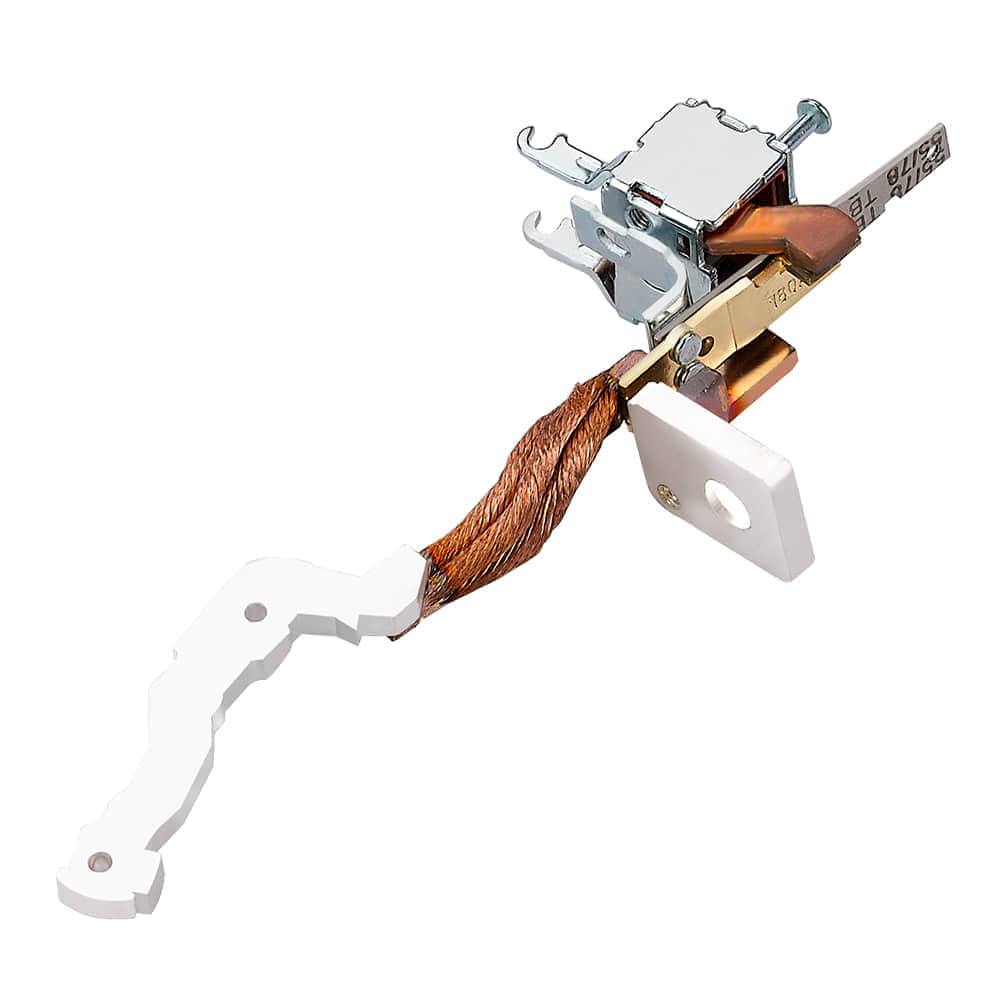

Metal stamping is a manufacturing process that involves shaping and forming metal sheets into desired parts and components. This process requires specialized equipment, such as stamping presses, dies, and tooling, to create parts with exceptional accuracy and consistency. From intricate designs to complex geometries, metal stamping manufacturers can produce a wide array of components used across industries like automotive, aerospace, electronics, and more. Technological Advancements In recent years, metal stamping parts manufacturing has witnessed remarkable technological advancements. Computer Numerical Control (CNC) systems have enhanced the precision of the stamping process, allowing manufacturers to achieve tolerances as low as a few micrometers. This level of accuracy ensures that the produced parts meet the strictest quality standards and fit seamlessly into the final product. Materials and Applications Metal stamping parts manufacturers work with various types of metals, including stainless steel, aluminum, copper, and special alloys. The choice of material depends on the intended application of the part. For instance, stainless steel might be preferred for its corrosion resistance in outdoor equipment, while copper’s excellent electrical conductivity might make it ideal for certain electronics components. The applications of metal stamped parts are virtually limitless. They can be found in everyday items like kitchen appliances and electronics, as well as in critical components for industries like telecommunications, medical devices, and automotive manufacturing. Quality Control and Efficiency Quality control is a cornerstone of metal stamping parts manufacturing. Manufacturers implement rigorous inspection processes to ensure that each part meets the required specifications. Advanced imaging systems and automated checks identify even the slightest deviations, minimizing the risk of defective parts reaching the market. Moreover, the efficiency of metal stamping processes significantly contributes to the overall production speed. High-speed stamping presses can rapidly produce large quantities of parts in a short time, making metal stamping a preferred choice for mass production while maintaining consistent quality. Customization and Innovation Metal stamping manufacturers also play a crucial role in bringing innovative designs to life. With computer-aided design (CAD) software and prototyping capabilities, they can collaborate with clients to develop custom parts tailored to specific needs. This flexibility allows for the creation of unique components that push the boundaries of what’s possible in various industries. Environmental Considerations In an era focused on sustainability, metal stamping parts manufacturers are adopting environmentally friendly practices. Efforts to reduce waste, recycle materials, and optimize energy usage are becoming integral to their operations. This not only minimizes the ecological footprint but also aligns with the values of clients who prioritize eco-conscious partnerships. The Road Ahead As technology continues to advance and industries evolve, metal stamping parts manufacturers will remain at the forefront of innovation. Their ability to adapt to changing demands, deliver impeccable quality, and contribute to a greener planet underscores their significance in the manufacturing landscape. From microscopic components to substantial parts, the art of metal stamping continues to shape the modern world.