In the realm of modern manufacturing, injection molding has emerged as a cornerstone technology, enabling the creation of intricate and high-quality parts for a myriad of industries. Injection molded parts manufacturers play a pivotal role in shaping the products that surround us, from everyday consumer goods to cutting-edge industrial components. This article delves into the world of injection molded parts manufacturing, exploring its processes, applications, and significance in today’s fast-paced market.

The Art of Injection Molding

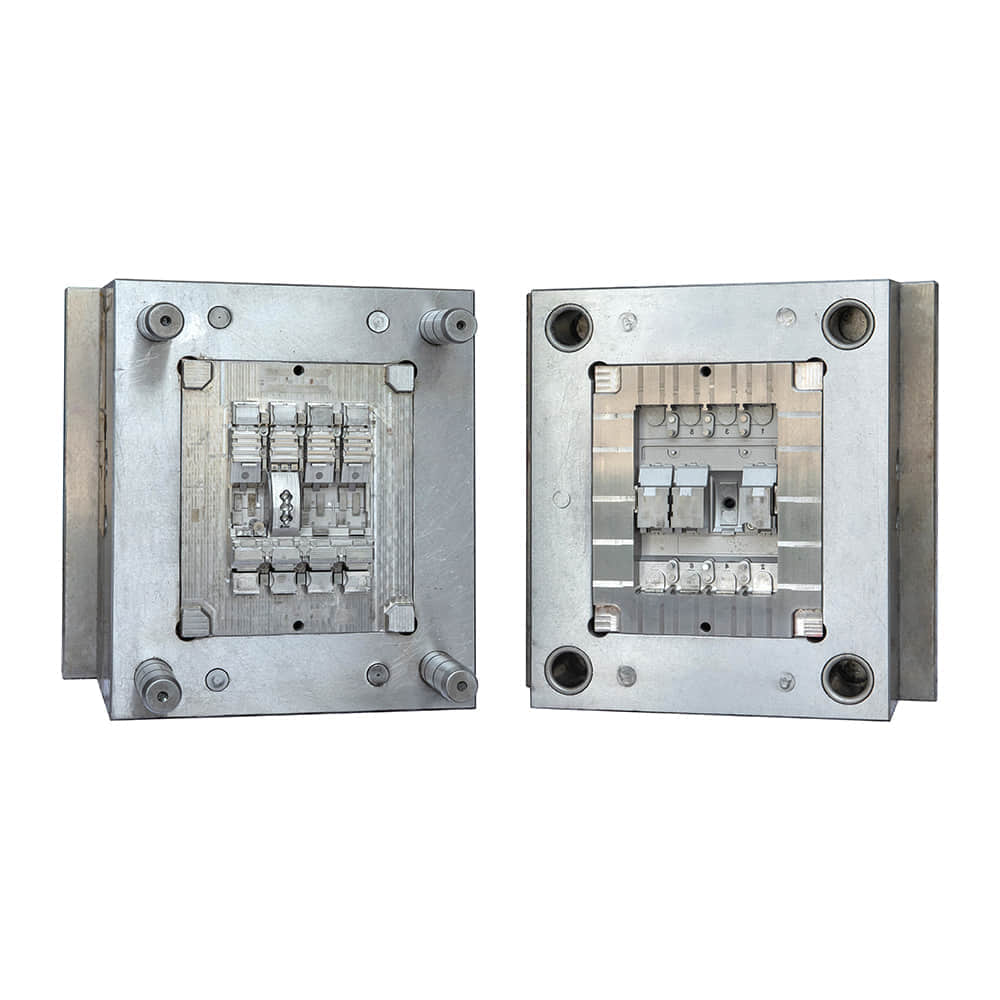

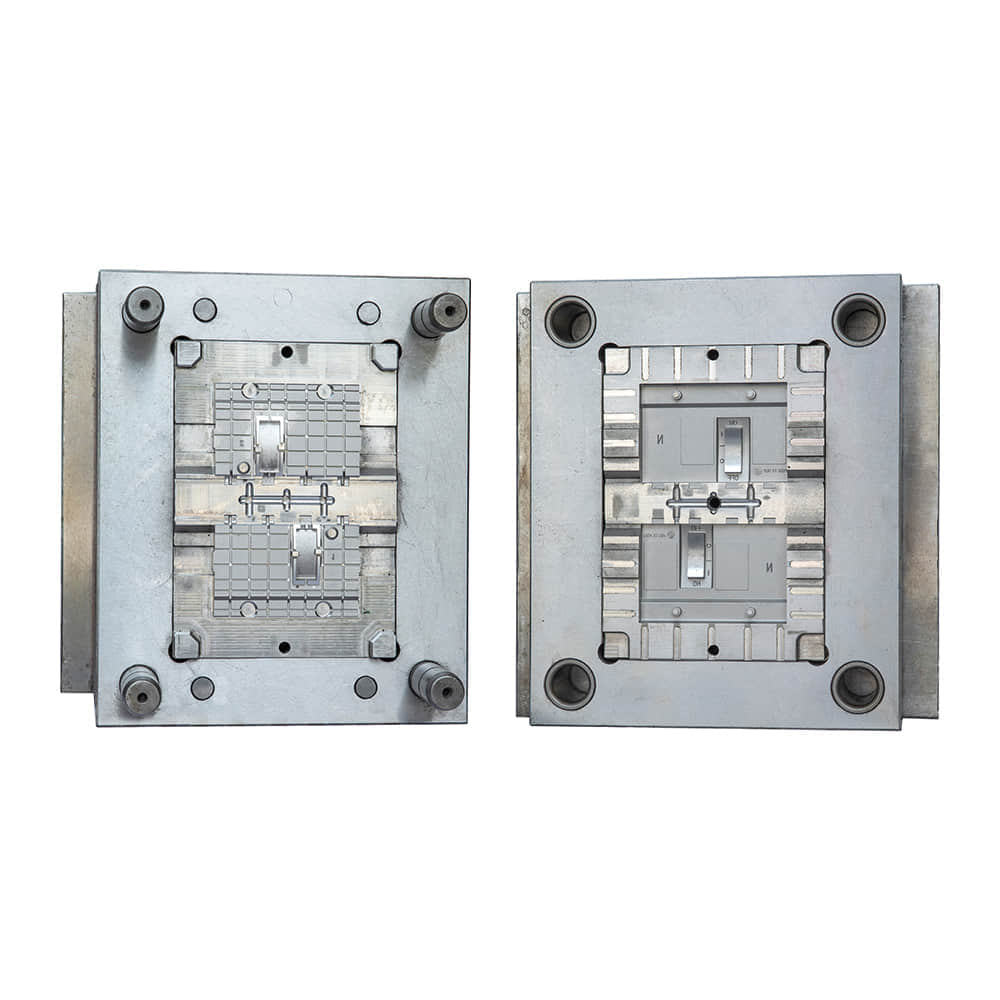

Injection molding is a manufacturing process that involves injecting molten material, usually plastic, into a mold cavity. This mold is meticulously crafted to mirror the desired shape and specifications of the final product. Once the material cools and solidifies, the mold is opened, and the newly formed part is ejected. This method excels in producing parts with exceptional precision, consistency, and complexity. The Manufacturing Process The journey of an injection molded part begins with meticulous design and engineering. Manufacturers collaborate closely with clients to understand their needs and craft detailed designs. Computer-aided design (CAD) software plays a crucial role in translating these concepts into precise digital models that guide the molding process. Next, the chosen polymer material, often in pellet form, is fed into the injection molding machine. Inside the machine, the pellets are melted and forced into the mold under high pressure. Cooling systems aid in solidifying the material swiftly, ensuring minimal cycle times. The mold then opens, revealing the freshly minted part. Stringent quality control measures are implemented at every stage to guarantee the part meets the desired specifications. Applications Across Industries Injection molded parts find their utility across a vast spectrum of industries. In the automotive sector, these parts contribute to the creation of durable and lightweight components such as bumpers, interior panels, and intricate engine parts. The electronics industry relies on injection molding for producing casings, connectors, and even micro parts within devices. Medical equipment, consumer goods, and packaging are additional domains benefiting from the precision and efficiency of injection molding. Significance in Modern Manufacturing The injection molding process offers numerous advantages that contribute to its prominence in modern manufacturing: Precision:The ability to replicate intricate details with minimal variation ensures the consistent production of high-quality parts. Cost-Efficiency:Once the mold is created, producing large quantities of parts becomes highly economical, making it a preferred choice for mass production. Material Variety:Injection molding supports an array of materials beyond plastics, including metals and ceramics, widening its scope of application. Reduced Waste:With minimal material wastage and the potential for recycling, injection molding aligns with sustainable manufacturing practices. Short Lead Times:The swift cycle of production from mold design to finished part facilitates rapid product development and market entry. Challenges and Innovations While injection molding offers numerous advantages, it also presents challenges such as initial mold creation costs and limitations in material choices for certain applications. However, ongoing advancements in materials science, mold-making technologies, and process optimization are steadily overcoming these limitations. Additionally, the integration of technologies like computer simulation and automation is enhancing efficiency, reducing errors, and expediting production. Conclusion Injection molded parts manufacturers are the unsung heroes behind the scenes, shaping the modern world with precision and innovation. Their expertise in transforming raw materials into intricate, functional parts serves as the foundation for various industries. As technology continues to evolve, injection molding is poised to push boundaries, enabling manufacturers to create even more complex, durable, and sustainable products that improve our lives in ways both big and small.