In the realm of modern manufacturing, precision and innovation are two pillars that uphold the industry’s progress. Among the unsung heroes of this sector are metal stamping parts manufacturers, whose expertise and craftsmanship play a pivotal role in shaping various products we encounter daily. This article delves into the world of metal stamping parts manufacturers, highlighting their significance, processes, and impact on diverse industries.

Defining Metal Stamping Parts Manufacturing

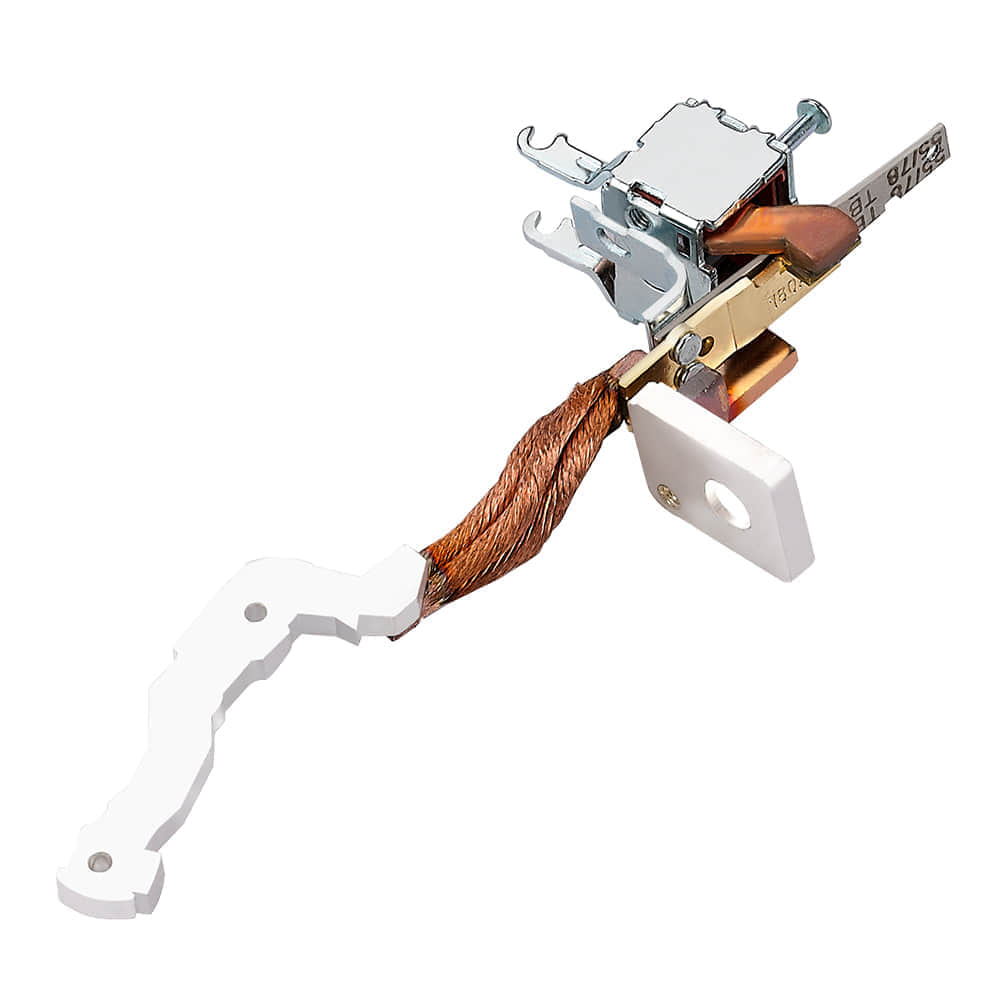

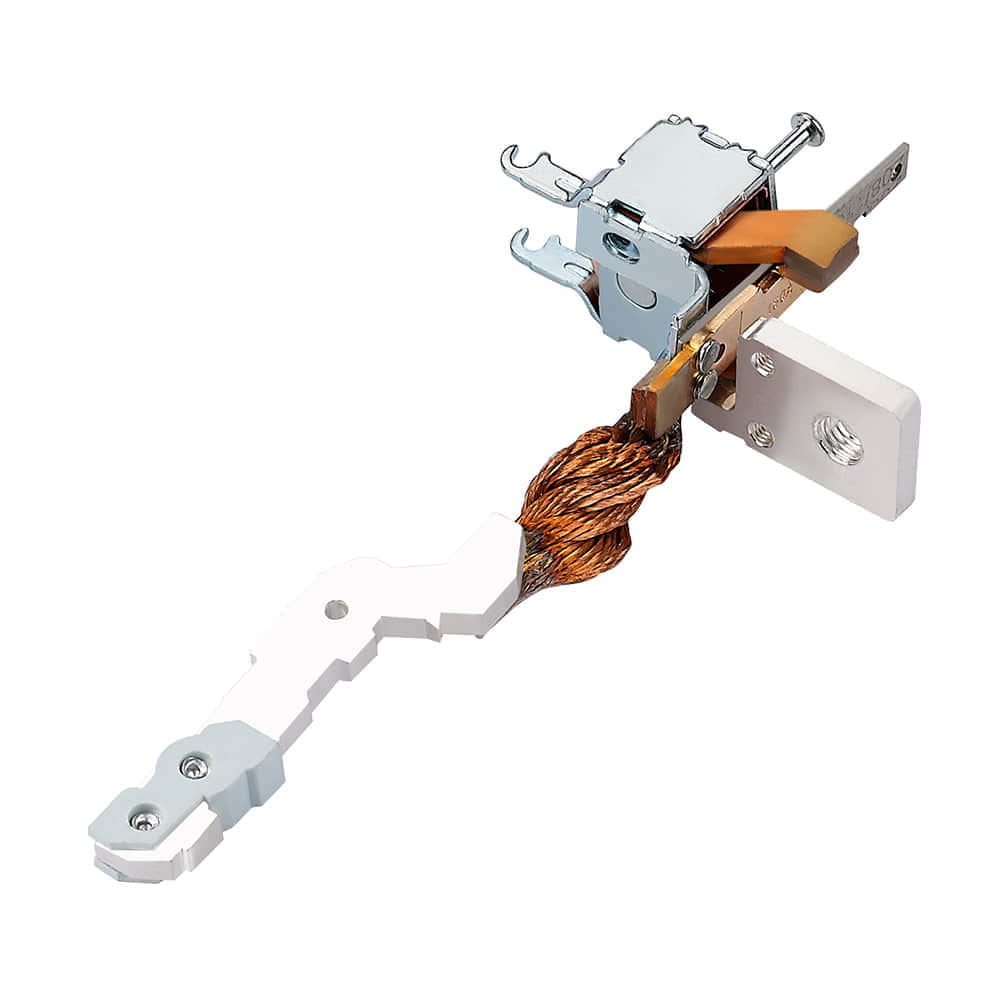

Metal stamping is a manufacturing process used to create intricate metal parts from sheet metal. It involves a series of precisely coordinated steps, where a metal sheet is fed into a stamping press that applies pressure to transform the material into the desired shape. This method is widely adopted due to its efficiency in producing high volumes of parts with consistent quality. From automotive components to household appliances, metal stamping parts are integral to a wide range of products. The Precision Paragon At the heart of metal stamping lies the pursuit of precision. Manufacturers employ advanced technologies such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems to meticulously plan each step of the process. These systems allow engineers to create detailed virtual prototypes and simulate the stamping process before actual production. This approach not only reduces the margin of error but also accelerates the development cycle of new parts. Materials and Machinery Metal stamping parts manufacturers work with an assortment of metals, including steel, aluminum, copper, and alloys. The choice of material depends on factors such as the intended application, durability requirements, and cost-effectiveness. Specialized machinery, including hydraulic presses, mechanical presses, and die sets, are utilized to execute the stamping process accurately. Dies, often customized for specific projects, shape the metal sheets into the desired forms. Diverse Applications The products of metal stamping find their way into countless industries. In the automotive sector, metal stamped parts are essential components of engines, transmissions, and chassis. The electronics industry relies on them for manufacturing connectors, terminals, and shielding components. Furthermore, metal stamped parts play a crucial role in aerospace, healthcare equipment, and even renewable energy systems. Their adaptability and precision make them indispensable in achieving desired functionality across sectors. Innovation and Sustainability Metal stamping parts manufacturers are not only adept at precision but are also driving innovation in sustainable manufacturing. As the world emphasizes environmental consciousness, these manufacturers are exploring ways to reduce waste, minimize energy consumption, and optimize material usage. Techniques such as “blank nesting” are employed to maximize the utilization of metal sheets, reducing scrap and conserving resources. The Human Touch While technology and machinery have revolutionized the industry, the human element remains irreplaceable. Skilled technicians and engineers monitor the entire process, ensuring quality control at every stage. Their expertise is especially critical in addressing unforeseen challenges and making real-time adjustments. The synergy between technological advancements and human proficiency is what enables metal stamping parts manufacturers to deliver top-notch products. Conclusion Metal stamping parts manufacturers are the unsung champions of precision manufacturing. Their expertise, combined with technological innovation, fuels industries across the spectrum. From automotive giants to intricate electronics, the influence of metal stamped parts is undeniable. As these manufacturers continue to refine their processes and embrace sustainability, we can expect an even more efficient and environmentally friendly production of the integral components that shape our modern world.