Injection molded parts have revolutionized the manufacturing industry, offering unparalleled precision, efficiency, and versatility in producing a wide range of products. This manufacturing process involves injecting molten material into a mold cavity, allowing it to cool and solidify, ultimately resulting in a meticulously crafted component. From everyday items to complex engineering solutions, injection molded parts play a pivotal role in shaping our modern world.

Precision Engineering: Crafting Perfection

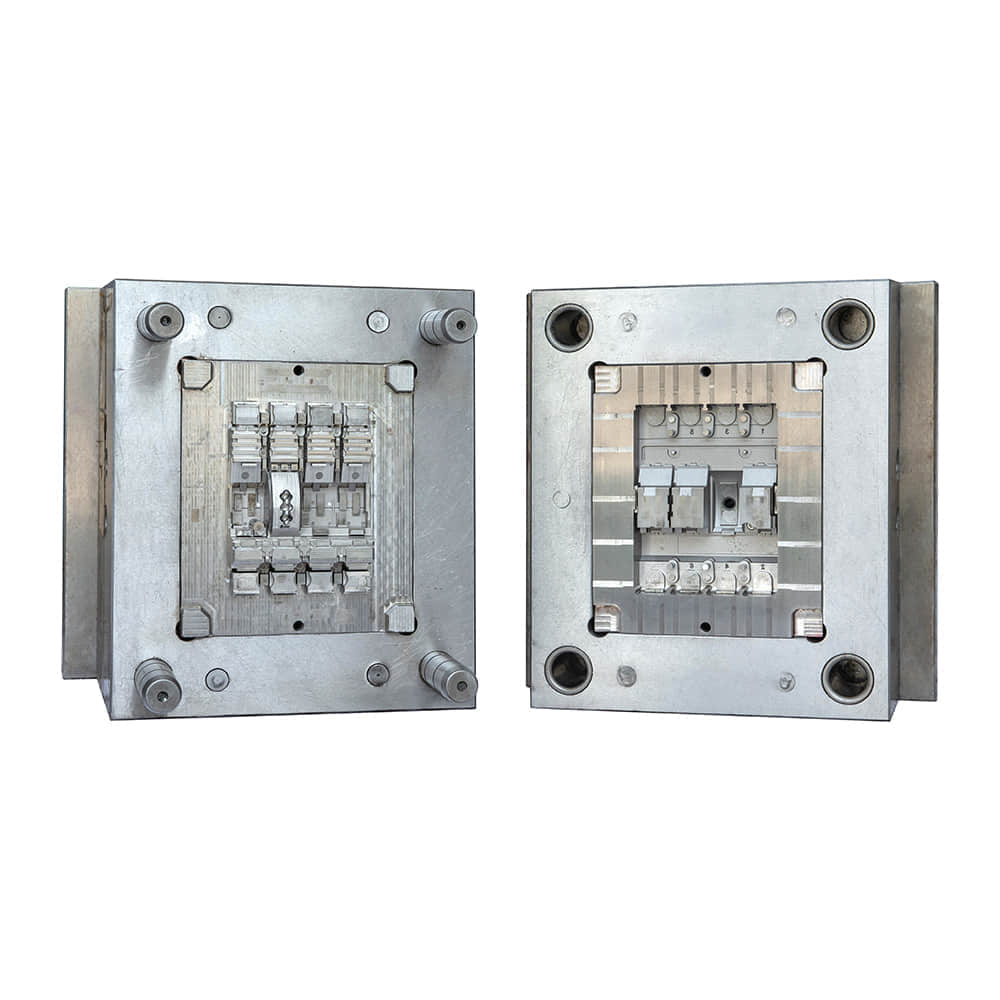

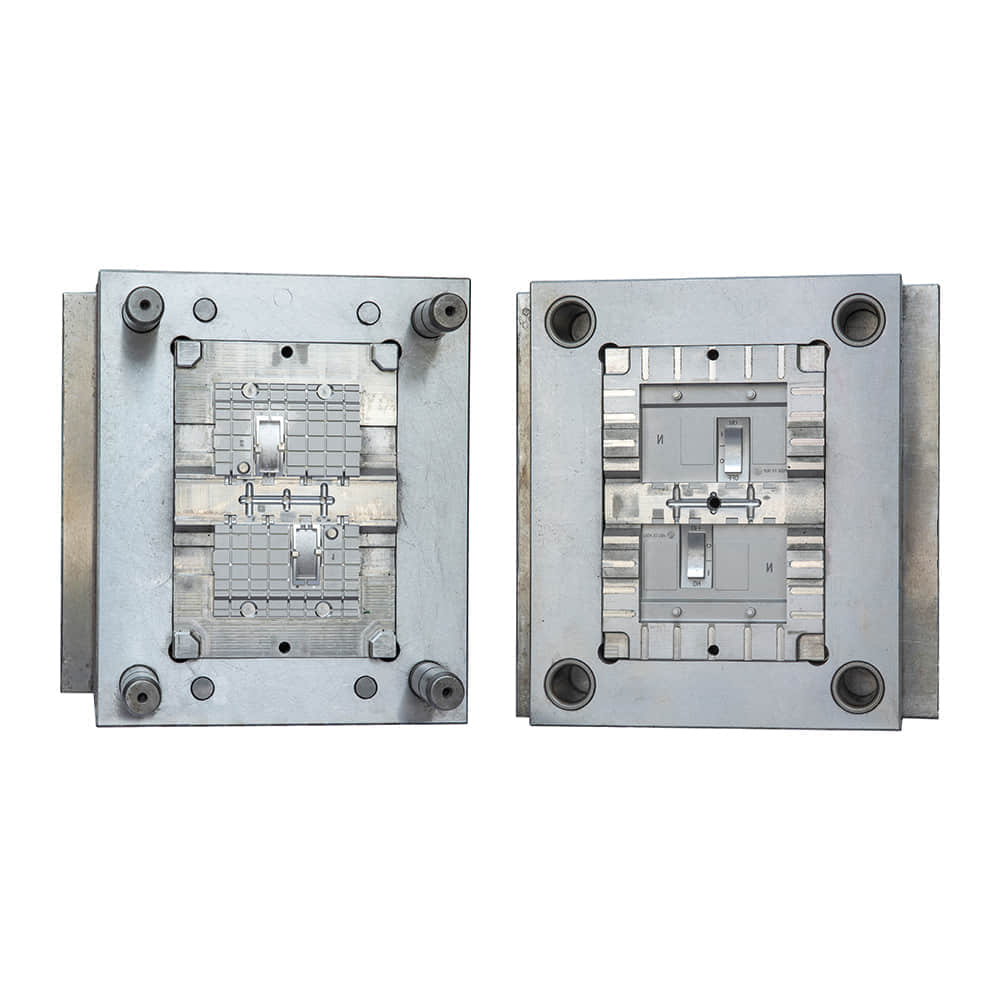

One of the most remarkable aspects of injection molded parts is the level of precision they offer. The molds used in this process are created with meticulous attention to detail, ensuring that each product meets exact specifications. The ability to reproduce intricate features consistently is a hallmark of injection molding, making it a preferred choice for industries where precision is paramount, such as aerospace, medical devices, and electronics. Efficiency Unleashed: Rapid Production Injection molding enables rapid and efficient production of parts on a large scale. The automation inherent in the process, coupled with the swift cooling and solidification of the molten material, allows for quick turnaround times. This efficiency not only reduces manufacturing costs but also caters to consumer demands for products to be available in a timely manner. The automotive industry, for example, benefits from injection molded parts for interior components, exterior panels, and even intricate engine parts. Material Variety: From Plastics to Metals The versatility of injection molded parts extends to the wide array of materials that can be utilized. While plastics remain the most commonly used material due to their cost-effectiveness and malleability, advancements in technology have also facilitated the injection molding of metals and ceramics. This versatility enables manufacturers to choose the material best suited for their specific application, ensuring the final product’s durability and functionality. Design Flexibility: Bringing Concepts to Life The injection molding process provides designers and engineers with unparalleled freedom in translating their concepts into reality. Complex shapes, undercuts, and varying wall thicknesses can all be achieved with this method. The ability to integrate multiple features into a single component reduces the need for assembly, enhancing both structural integrity and aesthetics. Whether it’s the sleek casing of a smartphone or the intricately designed housing of a medical device, injection molded parts enable designers to push the boundaries of innovation. Eco-Friendly Manufacturing: Minimizing Waste In recent years, the injection molding industry has taken significant strides towards sustainability. The process inherently generates less waste compared to traditional manufacturing methods, as excess material can often be reground and reused. Additionally, advancements in material science have led to the development of biodegradable and recycled materials suitable for injection molding. These eco-friendly initiatives reflect the industry’s commitment to reducing its environmental footprint. Challenges and Future Outlook While injection molded parts offer numerous benefits, challenges do exist. Designing intricate molds can be time-consuming and costly. Moreover, the initial investment in molds and machinery might deter small-scale manufacturers. However, with the advent of 3D printing for rapid prototyping and mold creation, these barriers are gradually diminishing. Looking ahead, the injection molding industry is poised for continuous growth. Advancements in automation, materials, and design software are driving the development of even more efficient and precise processes. As sustainability remains a global priority, injection molding’s capacity for eco-friendly production positions it as a key player in shaping a greener manufacturing landscape. Conclusion Injection molded parts have reshaped modern manufacturing, blending precision, efficiency, and versatility in a remarkable way. From aerospace components that require utmost precision to everyday products that demand rapid production, this process continues to drive innovation across industries. With a commitment to precision engineering, design flexibility, and sustainable practices, injection molding remains at the forefront of the manufacturing revolution, offering a world of possibilities for products that touch every aspect of our lives.