The marine industry, particularly offshore applications, demands robust and reliable equipment that can withstand the harshest conditions. One such critical component in this industry is the electric ball valve, which plays a vital role in regulating the flow of fluids and gases. China, being a global leader in manufacturing, has emerged as a significant producer of marine electric ball valves. These valves are designed to offer high performance, durability, and precision in a variety of offshore environments. In this article, we explore the role of China marine electric ball valve manufacturers, their innovations, and the importance of these products in the marine sector.

What is a Marine Electric Ball Valve?

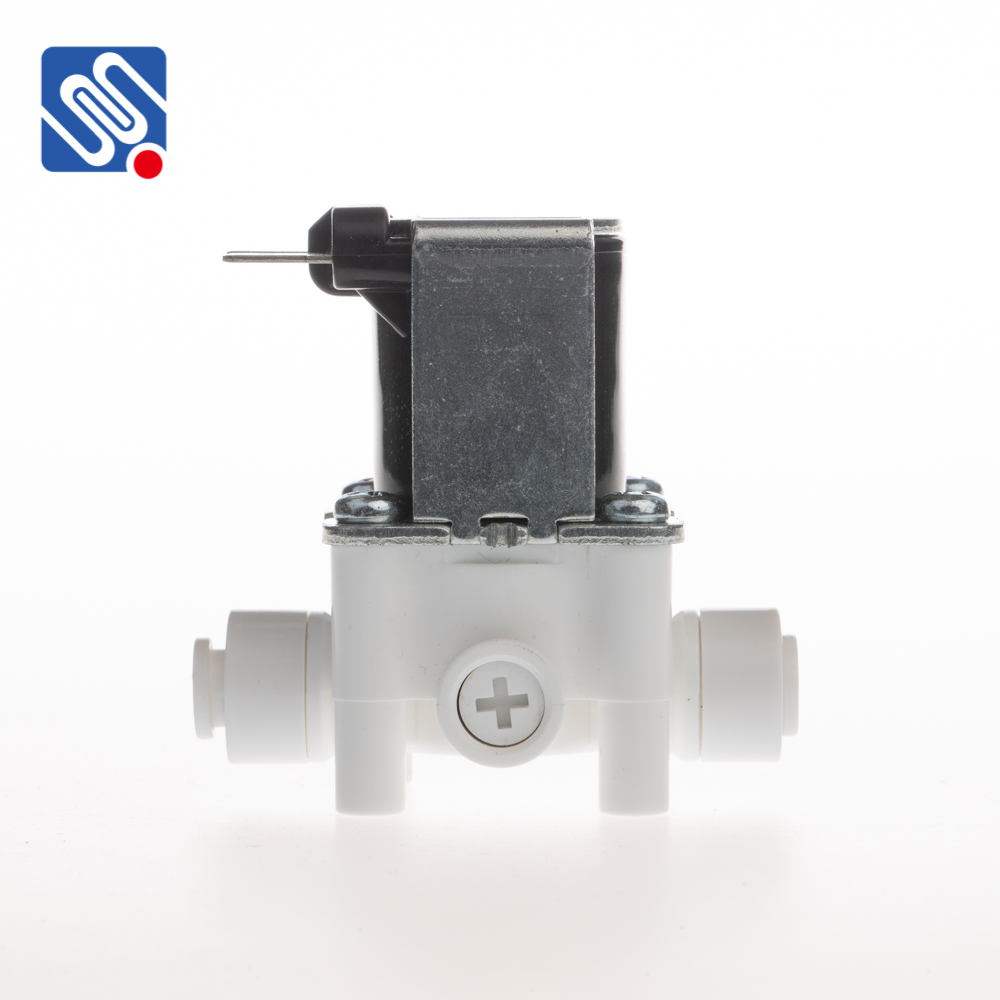

A marine electric ball valve is an automated valve designed to control the flow of liquids or gases in pipelines. It uses an electric actuator to open, close, or regulate the valve’s position, providing precise control over the flow. This feature makes electric ball valves ideal for use in complex systems where automation and remote control are necessary, such as offshore oil rigs, ships, and other maritime applications. Unlike traditional manual valves, electric ball valves are more efficient because they can be controlled remotely, reducing the need for manual intervention in hazardous or hard-to-reach environments. They are especially effective in marine applications, where the valves must be able to operate in extreme conditions like high pressures, fluctuating temperatures, and exposure to corrosive seawater.