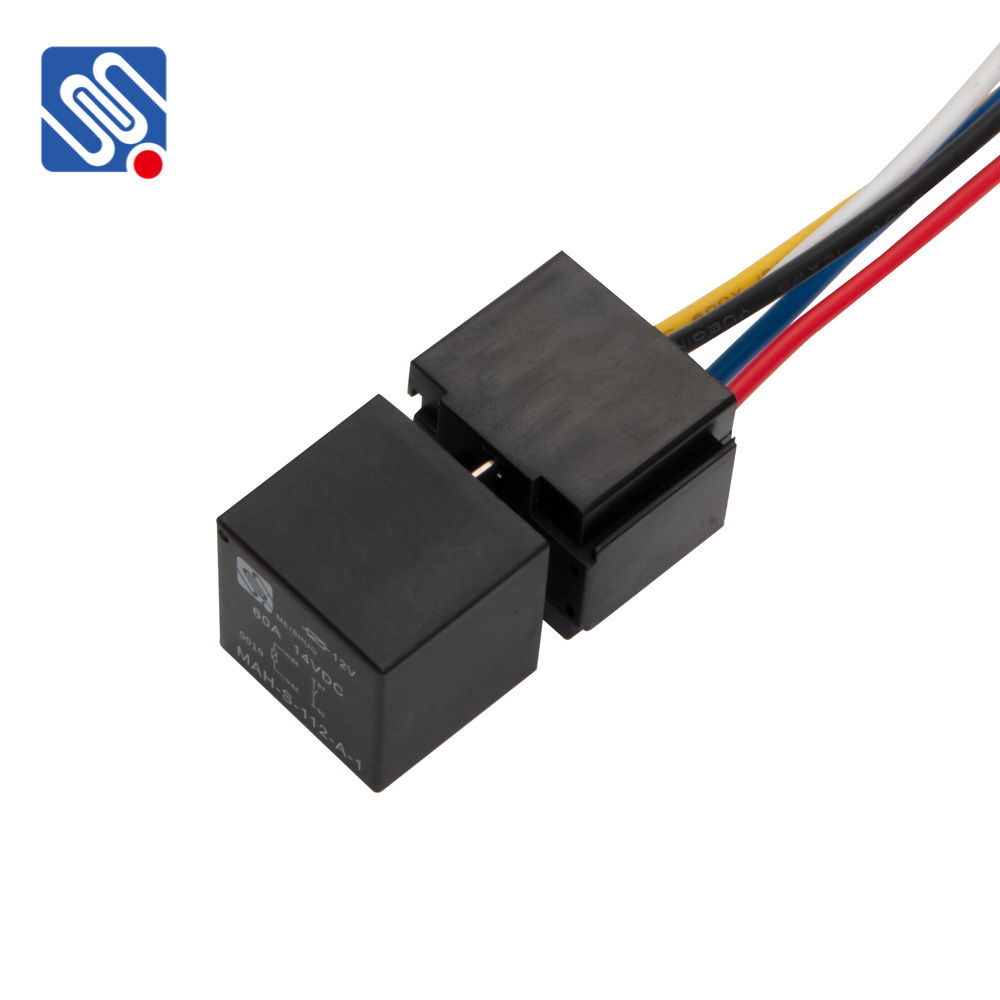

Relays are essential components in a variety of electrical systems, acting as switches that control the flow of electricity in circuits. With their ability to handle high voltages and currents while being controlled by a low voltage signal, relays play a crucial role in automation, industrial control, automotive, and many other applications. However, to ensure that a relay performs optimally and safely, it is important to understand its specifications. In this article, we will delve into the key parameters that define relay specifications and explain how to select the right relay for your needs.

1. Rated Voltage and Current One of the primary specifications of a relay is its rated voltage and current. These parameters define the maximum electrical load that the relay can handle both on the contact side (for switching) and on the coil side (for activation). The rated voltage specifies the voltage that the relay is designed to operate under, while the rated current indicates the maximum current the relay can safely carry through its contacts without damage. For instance, a common relay might have a 12V coil voltage and be able to handle 10A at 120V or 24V AC or DC on its contacts. It is essential to choose a relay with a voltage and current rating that matches or exceeds the requirements of the circuit it is controlling, ensuring that it can handle the electrical load without failure.