Relay materials play a critical role in modern electronics and electrical engineering, acting as essential components in various applications ranging from telecommunications to industrial automation. They facilitate the transmission, amplification, and control of signals, thereby ensuring efficient operation and effective communication in numerous systems. This article aims to explore the significance, types, applications, and future trends of relay materials.

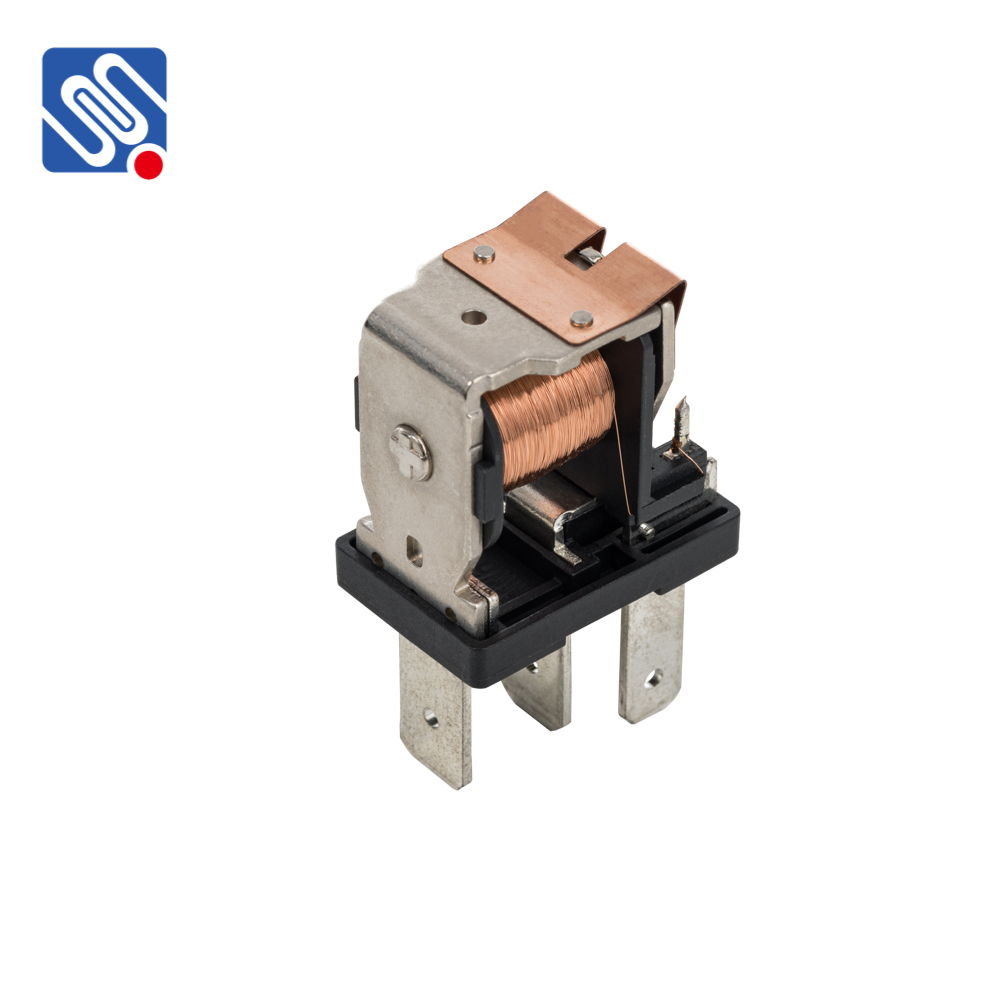

At the core of relay materials is their ability to handle electrical signals with precision and reliability. Most commonly, relay materials include conductive materials such as copper, silver, and gold, which are chosen for their excellent electrical conductivity. These metals form the backbone of relay operations, enabling the swift and efficient transfer of electrical signals. For instance, in a typical relay switch, these conductive elements allow for rapid opening and closing cycles, which is crucial in applications where timing is key. The choice of material depends on factors like cost, availability, and specific application requirements, leading to a diverse range of conductive materials used in various relay designs.