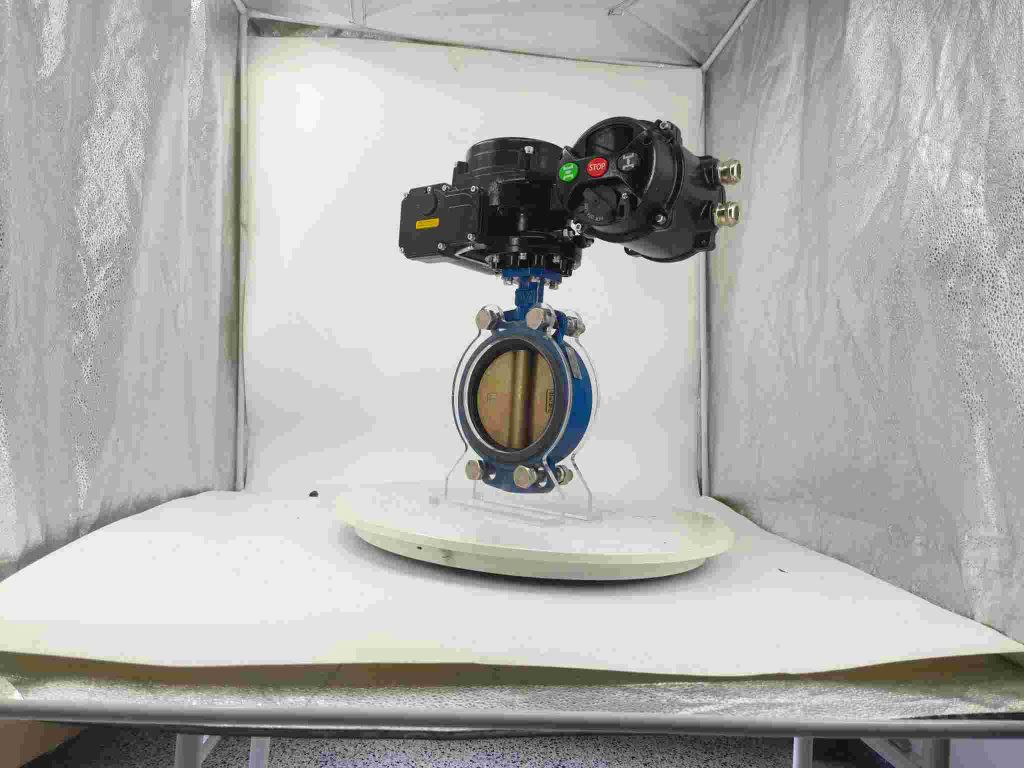

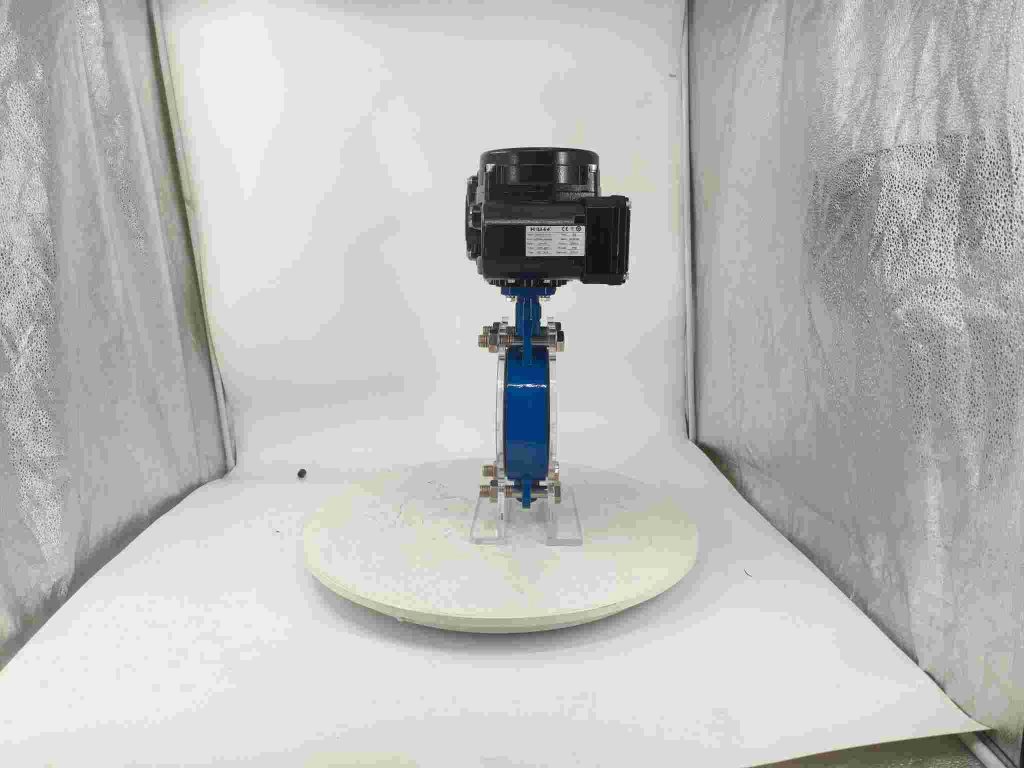

The WCB Marine Electric Ball Valve is an essential component for ensuring efficient, reliable, and safe fluid control in marine systems. With its precise control, durability, and resistance to the harsh conditions of the maritime environment, it has become a popular choice for various applications in shipbuilding and offshore industries. This article explores the significance of the WCB Marine Electric Ball Valve, its features, and its applications in marine systems.

What is a WCB Marine Electric Ball Valve?

The WCB Marine Electric Ball Valve combines the mechanical advantages of a traditional ball valve with the power and precision of an electric actuator. WCB refers to a specific material, Wrought Carbon Steel, which is known for its high strength, toughness, and resistance to wear and corrosion. In the marine context, the valve is specially designed to endure the demanding conditions of sea-based environments, where exposure to saltwater and extreme temperatures is common. Ball valves are widely recognized for their ability to offer quick shut-off and minimal flow resistance when fully open. In combination with an electric actuator, the WCB Marine Electric Ball Valve can be operated remotely, allowing for precise and automated control of the fluid flow. This feature is particularly beneficial in industries where safety, accuracy, and automation are crucial.