The demand for relays, especially the 12V 30A variants, is growing globally due to their wide range of applications in automotive, industrial, and electrical sectors. These relays are essential components that control the flow of electrical current, helping to protect circuits, ensure safety, and automate various processes. As one of the world’s leading manufacturing hubs, China plays a crucial role in supplying these highly reliable and cost-effective relays. In this article, we will explore the significance of China 12V 30A Relay Manufacturers, their contributions to the global market, and what to look for when sourcing these products.

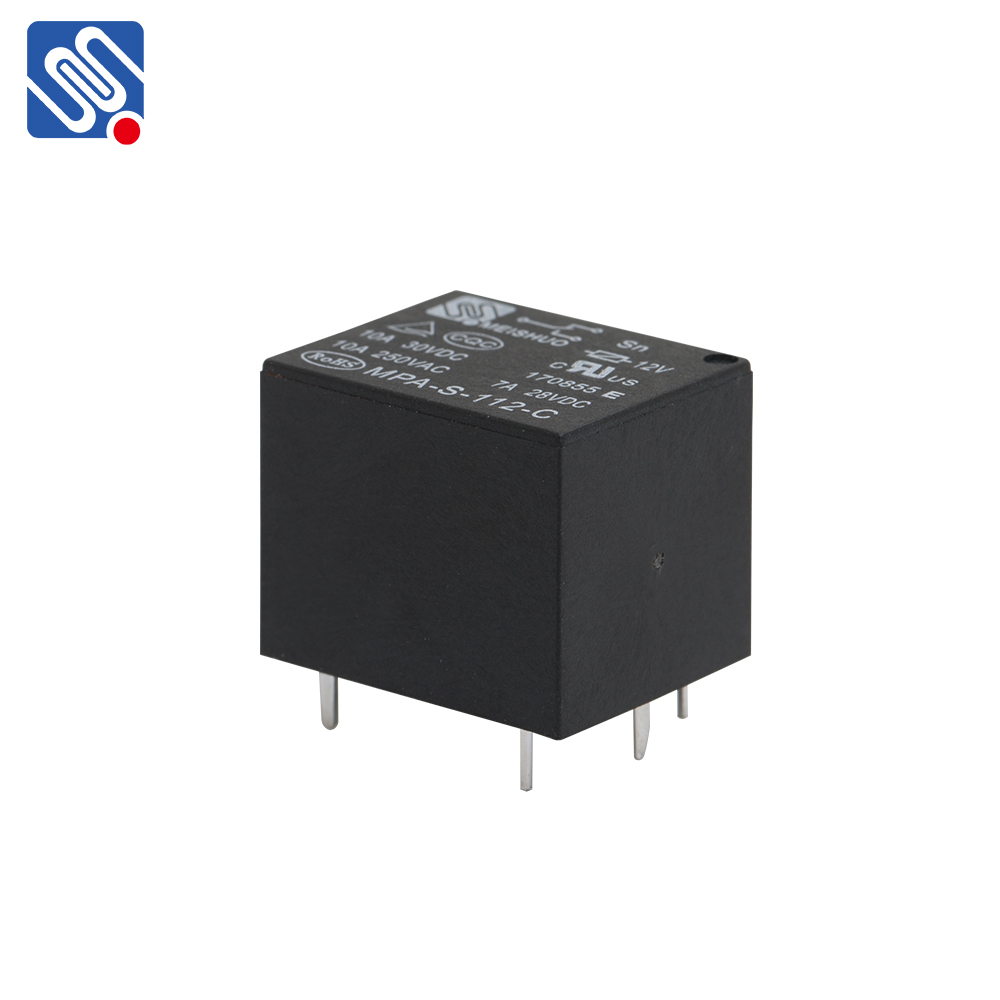

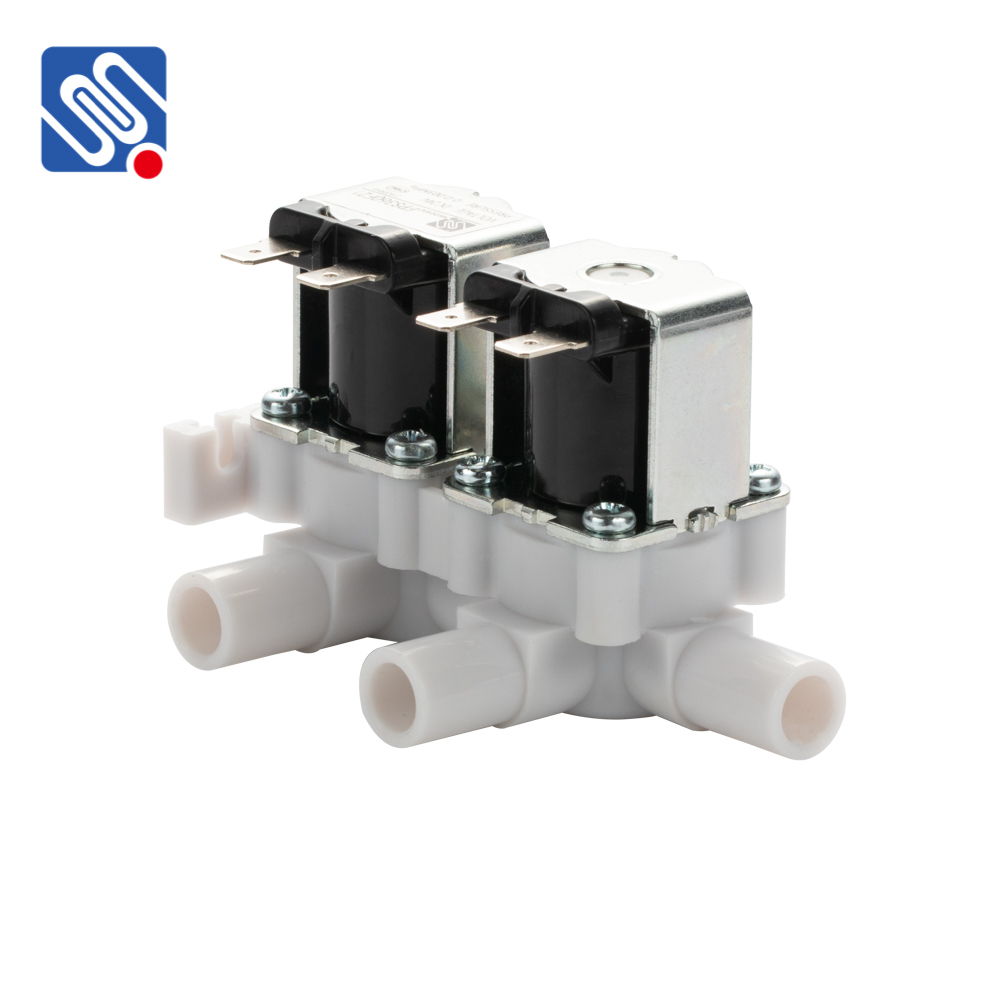

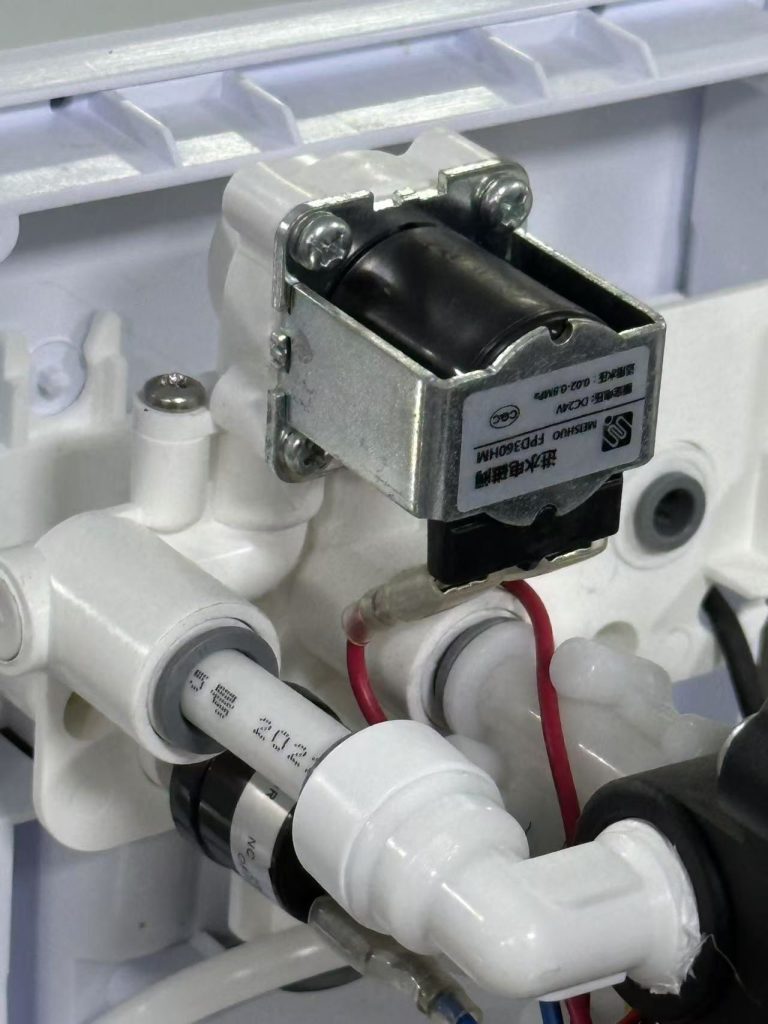

The Importance of 12V 30A Relays Relays are electrically operated switches that allow low-power circuits to control high-power devices. The 12V 30A relay is designed to handle a maximum current of 30 amps at 12 volts, making it suitable for a wide variety of applications. These include automotive electrical systems, industrial machinery, power distribution systems, and home automation systems. Automotive relays are perhaps the most common use case for 12V 30A relays. They are used to control components such as headlights, air conditioning systems, motors, and even alarm systems. Industrial applications benefit from these relays in the automation of machines and equipment, while in power distribution systems, they act as protective devices, disconnecting power in case of overload or malfunction.