A damper actuator is an essential component in heating, ventilation, and air conditioning (HVAC) systems, playing a crucial role in regulating airflow and maintaining the desired environment within buildings. These devices control the opening and closing of dampers—mechanisms that control the flow of air or gas through ducts, vents, or chimneys. This article will delve into the functionality, types, and significance of damper actuators in modern HVAC systems.

What is a Damper Actuator?

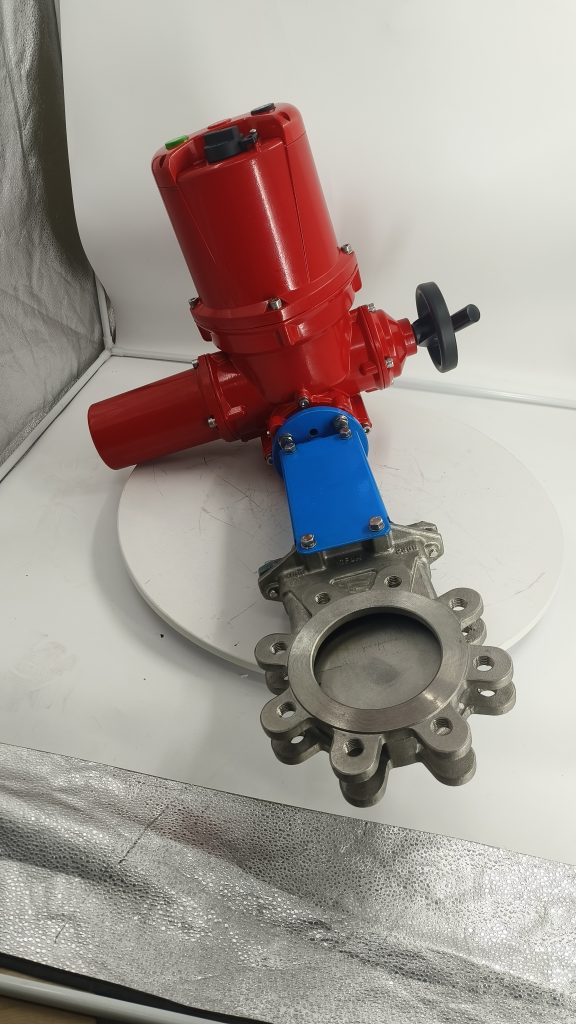

A damper actuator is a device responsible for operating dampers, which are commonly used to control airflow within air handling units, ventilation systems, and exhaust systems. It typically consists of an electric motor or pneumatic system that, when activated, moves the damper blades to either open or close based on input from a control system. These actuators are an integral part of the automated system, helping to ensure that airflow is balanced and adjusted according to heating or cooling needs. How Damper Actuators Work Damper actuators operate based on signals from a building’s central control system or thermostat. These signals indicate the necessary adjustments in air pressure, temperature, or humidity, prompting the actuator to adjust the damper position accordingly. The actuator itself contains a motor, gears, and a link mechanism that connects to the damper blades, enabling them to rotate. When a system detects that air distribution is out of balance or that a specific area requires more airflow, the damper actuator opens or closes the damper to optimize air circulation.