In modern technology, controlling temperature is essential for maintaining the stability and longevity of various devices and systems. A Temperature Control Relay plays a crucial role in regulating and managing the temperature of these systems. This article will delve into the functionality, applications, and benefits of Temperature Control Relays, explaining their significance in industries such as HVAC, automotive, and manufacturing.

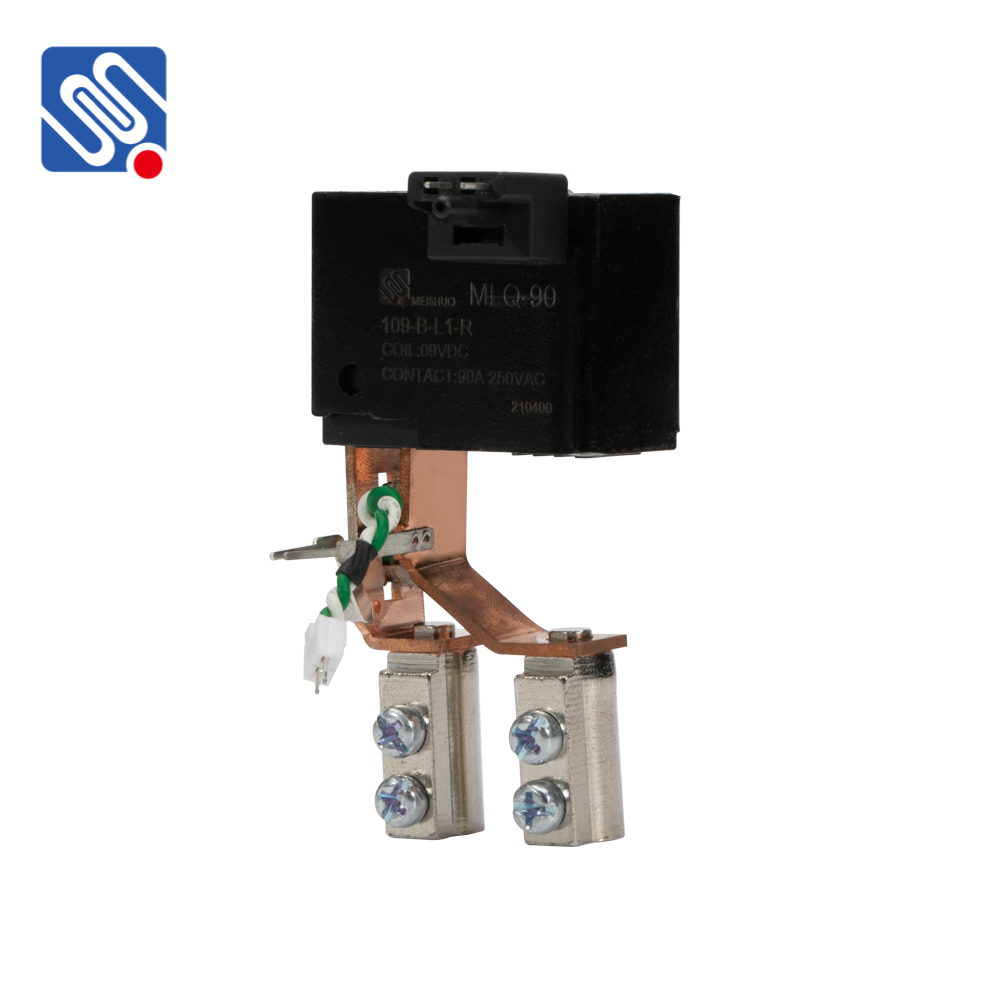

What is a Temperature Control Relay? A Temperature Control Relay is an electrical component designed to manage and regulate the temperature in a system. Essentially, it acts as an intermediary between a temperature sensor and a heating or cooling device, enabling the control system to maintain a desired temperature range. These relays work by receiving input from temperature sensors (like thermocouples or thermistors) and controlling an output signal to a heating or cooling device, such as a fan, heater, or compressor. The relay can be designed to either open or close the circuit based on the temperature readings, ensuring that the temperature stays within a predefined range. For instance, when the temperature exceeds the set threshold, the relay may switch off a heating system to prevent overheating. Conversely, when the temperature falls below the set point, the relay can activate a heater to bring the temperature back up.