A One Way Solenoid Valve is a critical component in modern automation systems that controls the direction of fluid flow, ensuring that it only moves in a designated direction. These valves are widely used in industrial, commercial, and residential applications where fluid or gas needs to be directed efficiently and safely. In this article, we will explore the working principle, types, advantages, and applications of one-way solenoid valves, highlighting their importance in various systems.

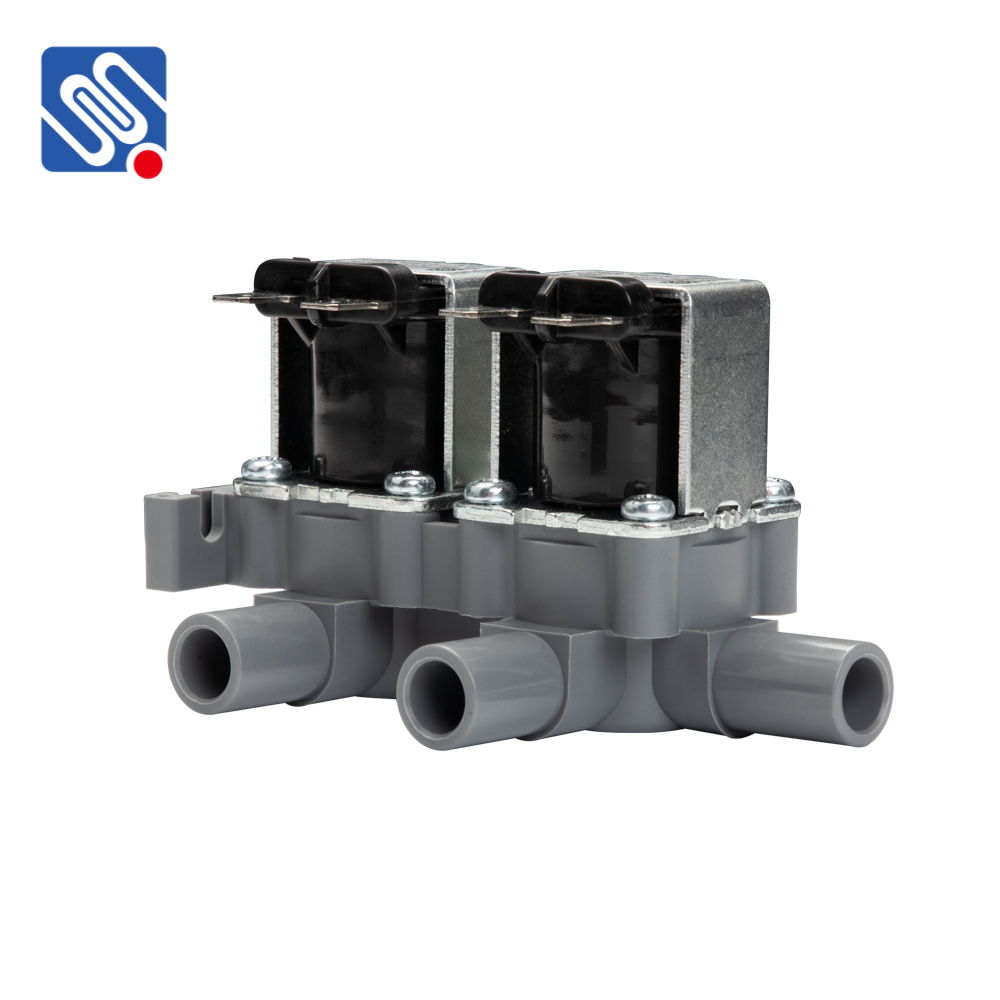

What is a One Way Solenoid Valve? A one-way solenoid valve is an electromechanical device that controls the flow of fluids (liquids, gases, or vapors) through a pipe or system by either allowing or blocking the flow in one direction. The solenoid, which is an electromagnet, is used to actuate the valve’s opening or closing mechanism. This type of valve is often used in applications where it is crucial to prevent backflow or reverse the direction of the fluid. Solenoid valves are typically installed in piping systems to regulate, control, or isolate the flow of substances. When an electrical current is supplied to the solenoid coil, it generates a magnetic field that moves a plunger or diaphragm to open or close the valve. The valve can be either normally open (NO) or normally closed (NC), depending on the specific requirements of the application.