In the world of manufacturing and engineering, precision and efficiency are paramount. Among the myriad of techniques that have transformed the way we create products, metal stamping stands out as a cornerstone of modern industry. Metal stamping parts, born from innovative engineering and cutting-edge technology, play a pivotal role in various sectors, ranging from automotive to electronics and beyond.

A Glimpse into Metal Stamping:

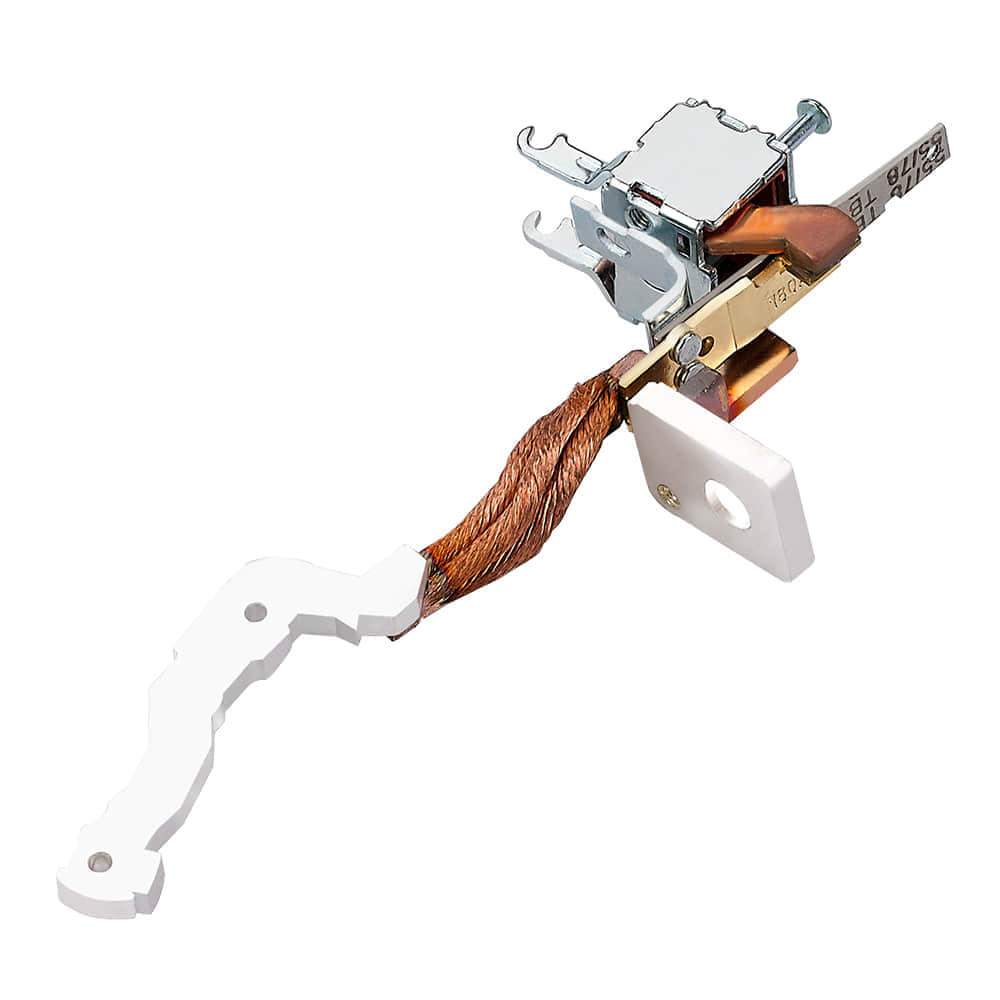

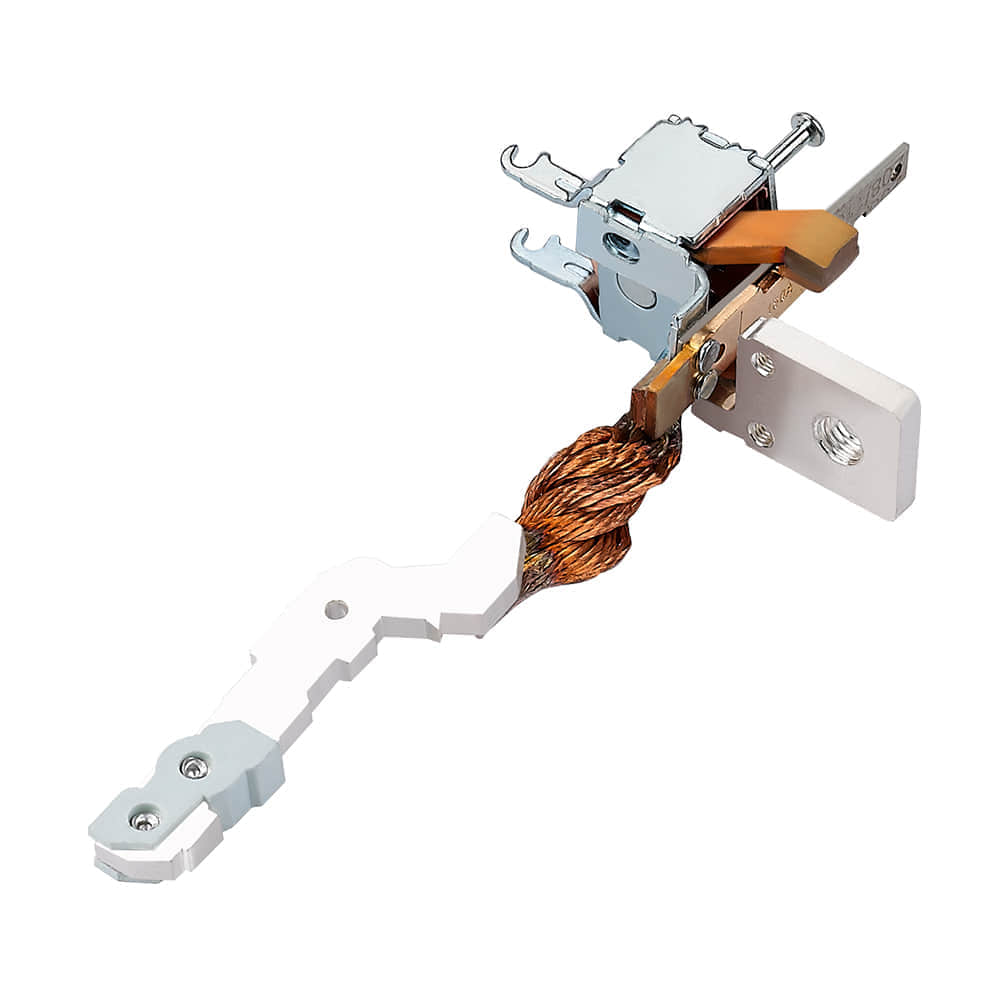

Metal stamping is a manufacturing process that involves shaping flat metal sheets into intricate designs using specialized machinery and tooling. The process encompasses various stages, including blanking, piercing, bending, and forming. The result is a range of components that are used in the assembly of products we encounter daily. The Precision Advantage: One of the key reasons metal stamping has become so indispensable is its precision. Computer-controlled systems guide the machinery, ensuring that each part is produced with utmost accuracy. This precision not only guarantees the quality of the parts but also allows for seamless integration into larger assemblies, reducing production delays and enhancing overall efficiency. Applications Across Industries: Automotive Industry:Metal stamping parts are the unsung heroes of the automotive world. From structural components that ensure safety to intricate parts that contribute to performance, metal stamping plays a vital role. Brackets, chassis elements, and even engine components owe their existence to this process. Electronics Sector:The electronics industry benefits from metal stamping’s ability to produce intricate parts at high volumes. Smartphone casings, connectors, and heat sinks are just a few examples of components that rely on the precision and consistency that metal stamping provides. Medical Equipment:In the realm of medical devices, precision is non-negotiable. Metal stamping answers this demand by producing parts used in devices like pacemakers, surgical instruments, and diagnostic equipment. The use of stamped parts not only ensures accuracy but also adheres to the strictest safety standards. Material Diversity and Sustainability: Metal stamping isn’t limited to a single type of metal. Depending on the application, various materials such as stainless steel, aluminum, copper, and alloys can be used. This flexibility allows manufacturers to tailor components to their exact needs, optimizing performance and durability. Moreover, advancements in sustainable manufacturing have extended to metal stamping, with the recycling of scrap metal and the reduction of waste becoming integral to the process. Challenges and Future Innovations: While metal stamping has revolutionized manufacturing, challenges remain. The complexity of certain designs and the need to maintain high tolerances can be demanding. However, ongoing technological advancements are addressing these challenges. Additive manufacturing, for instance, is beginning to complement traditional metal stamping, enabling the production of even more intricate parts with enhanced efficiency. Conclusion: Metal stamping parts are the building blocks of modern industry, shaping everything from the vehicles we drive to the devices we rely on. Their precision, versatility, and sustainable nature make them an invaluable asset in the manufacturing landscape. As technology continues to evolve, metal stamping is poised to embrace new innovations, further solidifying its role in shaping the world around us.