Metal Stamping Die: Precision Tools Shaping the Future of Manufacturing

In the realm of modern manufacturing, precision and efficiency are paramount. One of the key technologies driving these aspects is the metal stamping die, a tool that has revolutionized the way metal components are fabricated. With its intricate design, advanced materials, and diverse applications, the metal stamping die has emerged as an indispensable asset in various industries.

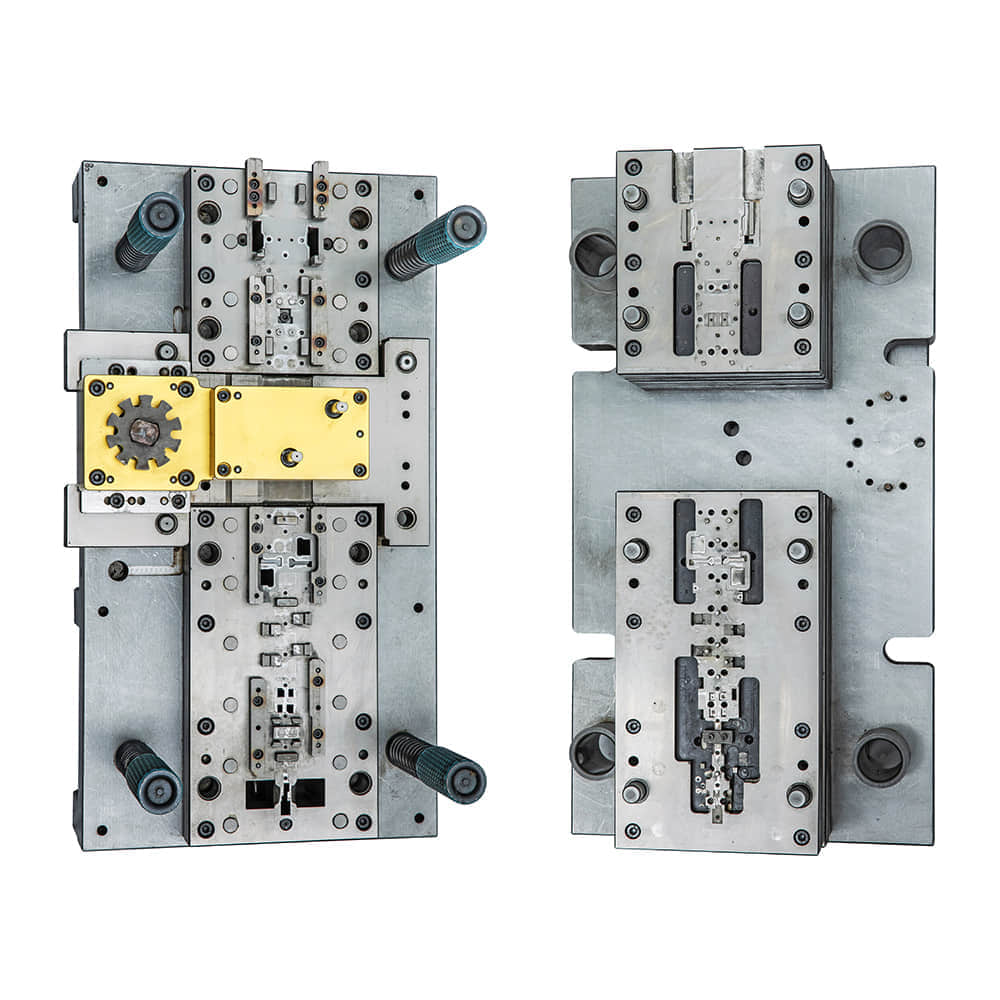

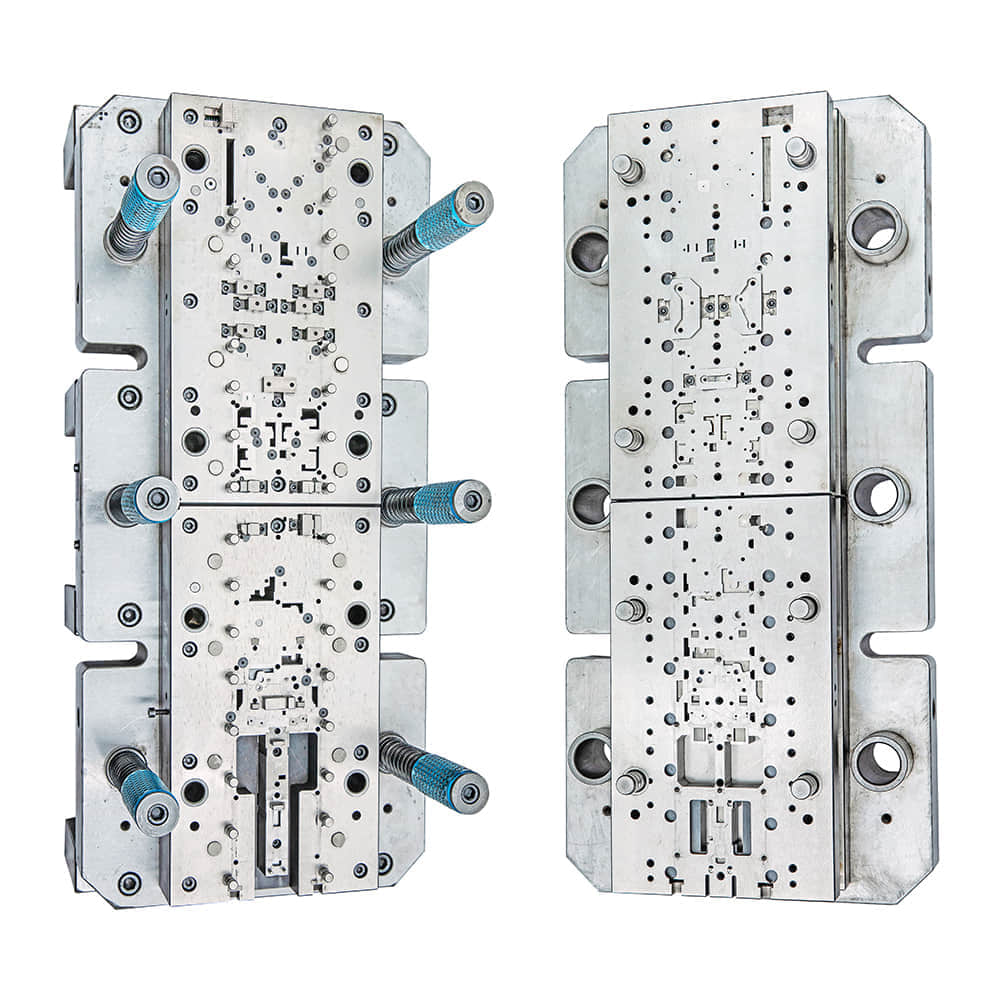

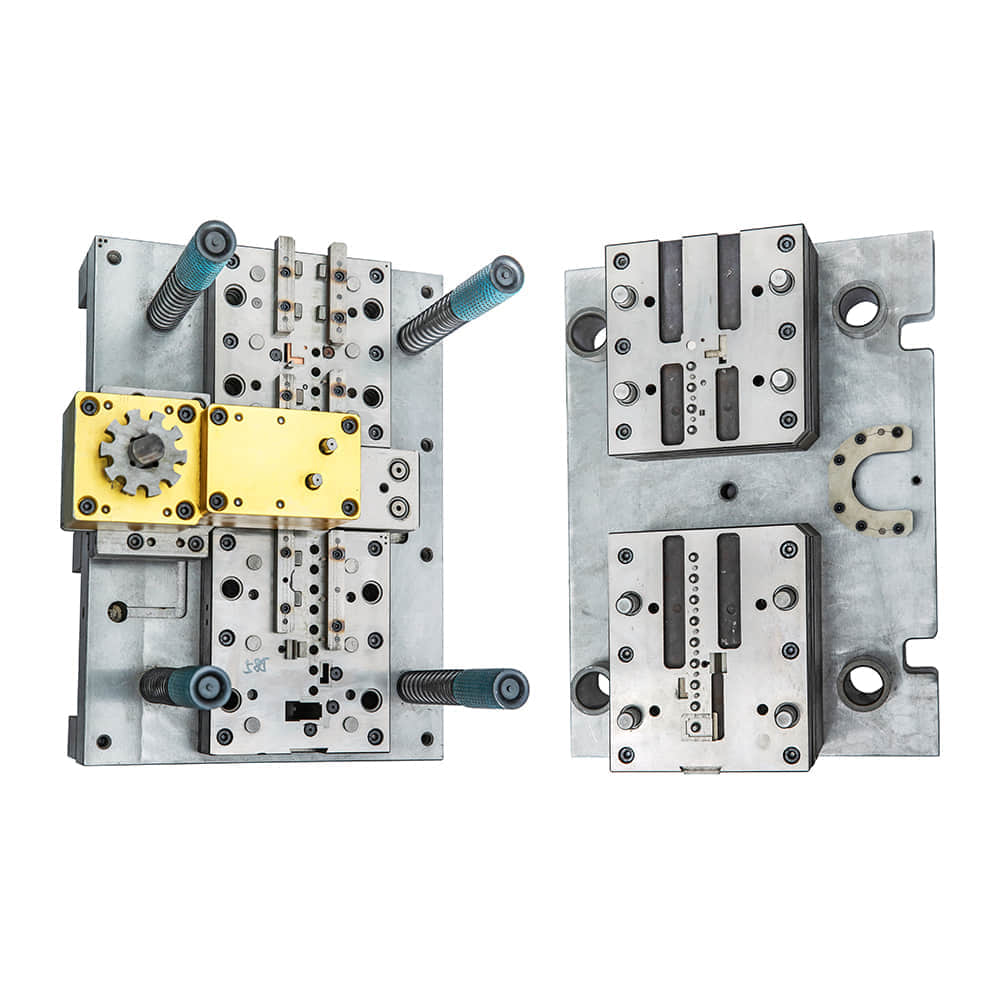

Metal stamping dies are specialized tools used to shape and cut metal sheets into desired forms and sizes with remarkable accuracy. These dies consist of two main parts: the punch and the die. The punch delivers force, while the die provides the desired shape or cut. The metal is placed between these two components, and upon applying pressure, the desired shape is obtained. This process is extensively used in industries such as automotive, aerospace, electronics, and appliances. The evolution of metal stamping dies has been extraordinary. Traditional dies were made from simple materials and were limited in their capabilities. However, advancements in metallurgy and machining techniques have led to the development of high-strength, wear-resistant materials such as carbide and tool steel. These materials enable the creation of complex, intricate dies that can withstand high pressures and repetitive operations without compromising quality. The automotive industry, for instance, heavily relies on metal stamping dies to create components that are essential for vehicle assembly. From body panels to engine parts, metal stamping plays a crucial role in shaping the vehicles we drive. The precision of these dies ensures that each part fits perfectly, contributing to the overall safety and performance of the automobile. Furthermore, the aerospace industry benefits from metal stamping dies by producing intricate parts used in aircraft construction. The ability to mass-produce complex components with minimal variations ensures consistency and reliability in aviation technology. This, in turn, enhances passenger safety and reduces maintenance requirements. The electronics sector also embraces metal stamping dies for manufacturing circuitry components, connectors, and housings. The precision of these dies is instrumental in maintaining the functionality of electronic devices, while their high-speed production capabilities cater to the demands of the consumer electronics market. In the household appliance industry, metal stamping dies are responsible for shaping various parts of appliances like refrigerators, washing machines, and ovens. The efficiency of the stamping process contributes to cost-effective production, making quality appliances accessible to a broader range of consumers. While metal stamping dies have already revolutionized manufacturing, ongoing advancements continue to refine and expand their applications. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies have streamlined the die design process, allowing for even greater precision and customization. Simulation software enables engineers to anticipate potential challenges and optimize the die’s performance before it’s physically created, reducing development time and costs. Moreover, the integration of robotics and automation has further elevated the efficiency of metal stamping processes. Robotic systems can swiftly load and unload materials, execute intricate stamping procedures with consistent force, and perform quality control inspections, all while minimizing the risk of human error and ensuring a safe working environment. In conclusion, metal stamping dies represent a pinnacle of precision and efficiency in modern manufacturing. Their evolution from simple tools to complex, highly specialized components has catalyzed progress across various industries. The automobile, aerospace, electronics, and household appliance sectors all benefit from the accuracy and speed that metal stamping dies offer. As technology continues to advance, these dies will undoubtedly play an increasingly pivotal role in shaping the future of manufacturing.