Metal Stamping Die: Precision Crafting for Manufacturing Excellence

In the intricate world of metal manufacturing, the role of metal stamping dies is paramount. These unassuming tools play a crucial role in shaping and forming metal sheets into various products we use daily, from automotive components to household appliances. The art and science of metal stamping die design and fabrication are essential for achieving precision, consistency, and efficiency in modern manufacturing processes.

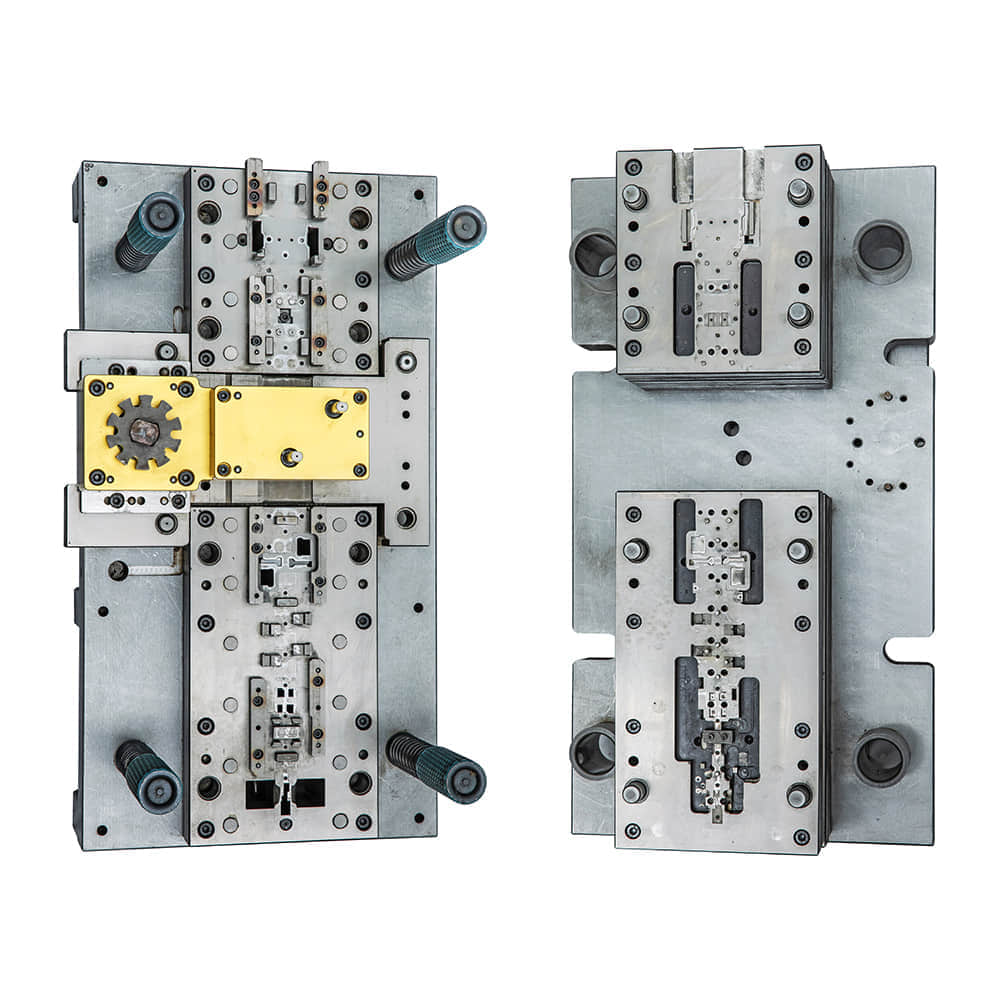

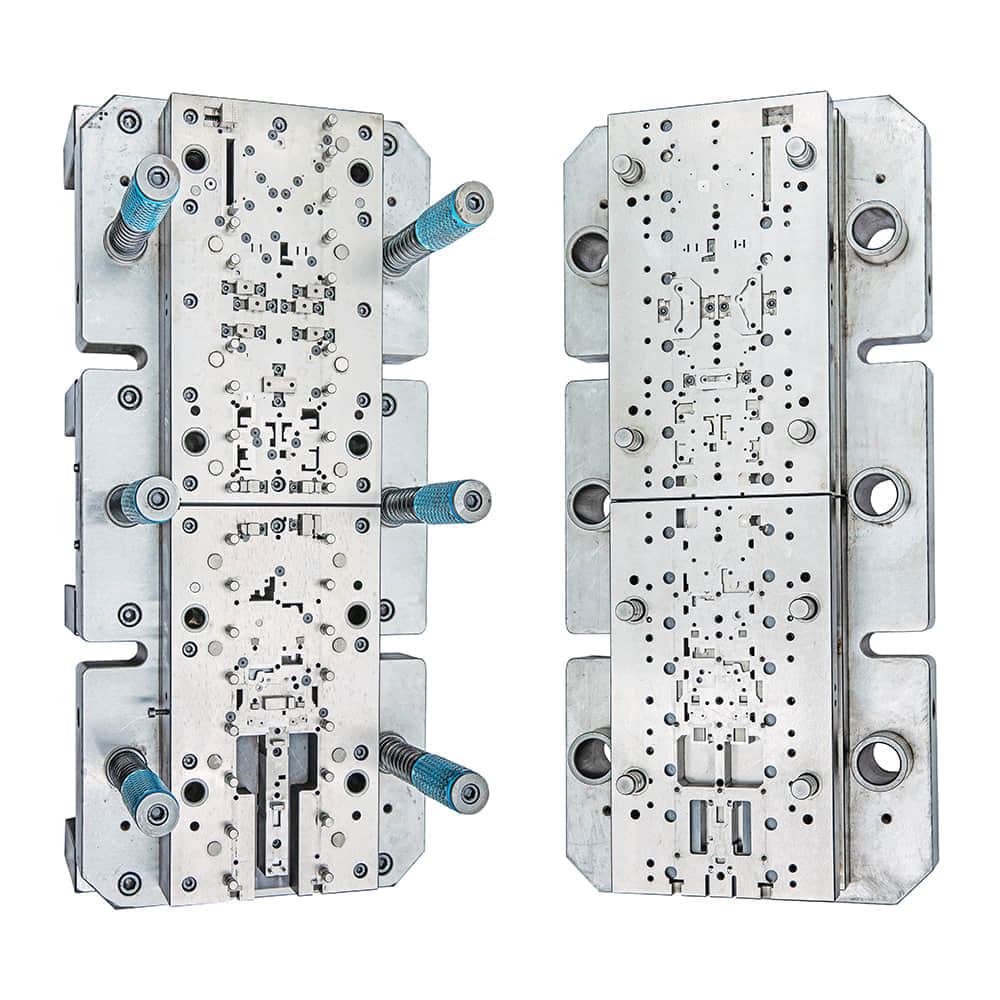

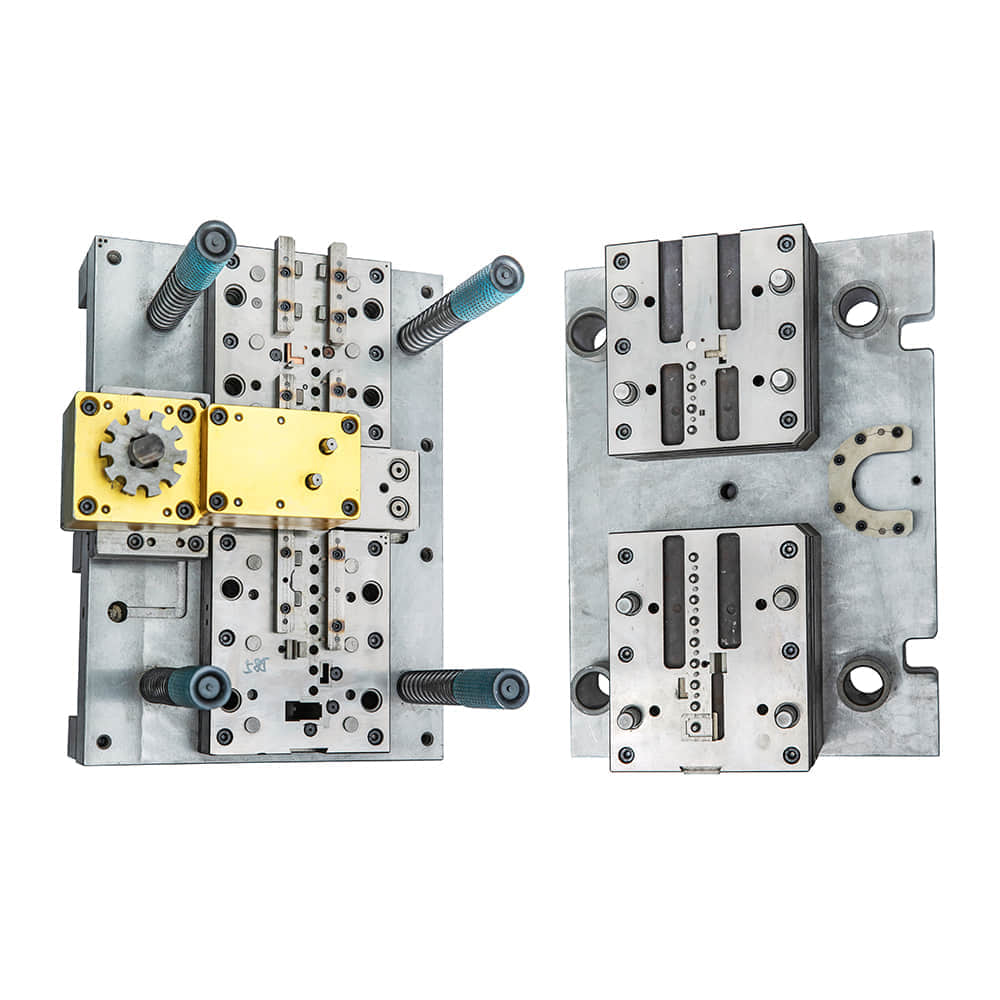

Understanding Metal Stamping Die: A metal stamping die is a specialized tool that is used to cut, shape, or mold metal sheets into desired forms. These dies come in various shapes and sizes, each designed for specific applications. The die itself is often made from hardened steel to withstand the repetitive forces and stresses involved in the stamping process. It consists of two main components: the punch and the die cavity. The punch applies force, while the die cavity provides the desired shape, allowing metal to be transformed with remarkable accuracy. The Process of Metal Stamping: The process begins with the design and engineering of the metal stamping die. Modern manufacturing relies heavily on computer-aided design (CAD) software to create intricate and precise die designs. Once the design is complete, the actual fabrication of the stamping die takes place. This involves skilled toolmakers who meticulously craft the die to exact specifications, considering factors like material type, thickness, and required tolerances. Once the stamping die is ready, it’s integrated into a stamping press. A metal sheet is placed in the press, and as the press descends, the stamping die’s punch forces the metal into the die cavity. The metal takes on the shape of the die, and the final product is born. This process is not only fast and efficient but also highly repeatable, ensuring consistency in every piece produced. Applications and Advantages: Metal stamping dies find applications in various industries, including automotive, aerospace, electronics, and more. From intricate electronic components to large automotive panels, metal stamping dies enable the mass production of parts with tight tolerances and consistent quality. One of the significant advantages of metal stamping dies is their cost-effectiveness for mass production. Once the initial investment in die design and fabrication is made, the cost per part decreases significantly. The high-speed production capabilities of stamping presses further contribute to reducing manufacturing costs. Challenges in Metal Stamping Die Design: Designing metal stamping dies is a complex task that requires a deep understanding of material behavior, mechanical engineering principles, and manufacturing processes. Achieving the right balance between sharpness and durability of the die, as well as minimizing wear and tear over millions of cycles, is a constant challenge. Moreover, factors like material springback (the tendency of metal to return to its original shape after forming) and variations in material properties can affect the accuracy of the final product. The Future of Metal Stamping Die: As manufacturing technologies continue to evolve, so do metal stamping dies. Advanced simulations and modeling techniques allow engineers to predict and optimize the performance of stamping dies before they are even fabricated. Additionally, the integration of sensors and real-time monitoring systems enables manufacturers to detect issues early, reducing downtime and ensuring consistent product quality. In conclusion, metal stamping dies are the unsung heroes of modern manufacturing. Their precision, efficiency, and reliability are the backbone of various industries, driving innovation and economic growth. As technology progresses, these tools will continue to evolve, further enhancing their role in shaping the products that define our daily lives.