In the realm of modern industrial manufacturing, precision and efficiency are paramount. One crucial element that underpins the production of a myriad of metal products is metal stamping dies. These intricate tools are the unsung heroes behind the scenes, enabling the mass production of components that form the backbone of industries ranging from automotive to electronics. In this article, we delve into the world of Metal Stamping Die OEM Manufacturers, exploring their significance, capabilities, and contributions to industrial success.

The Crucial Role of Metal Stamping Die OEM Manufacturers

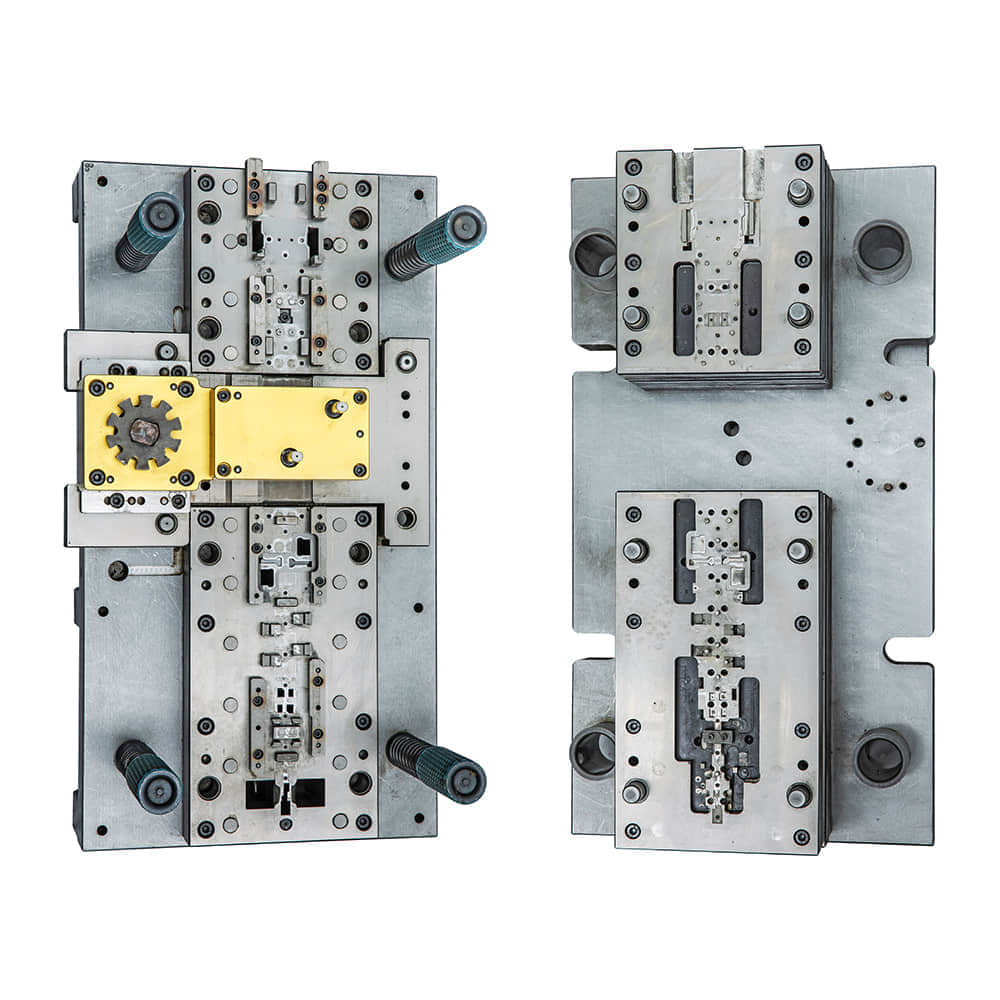

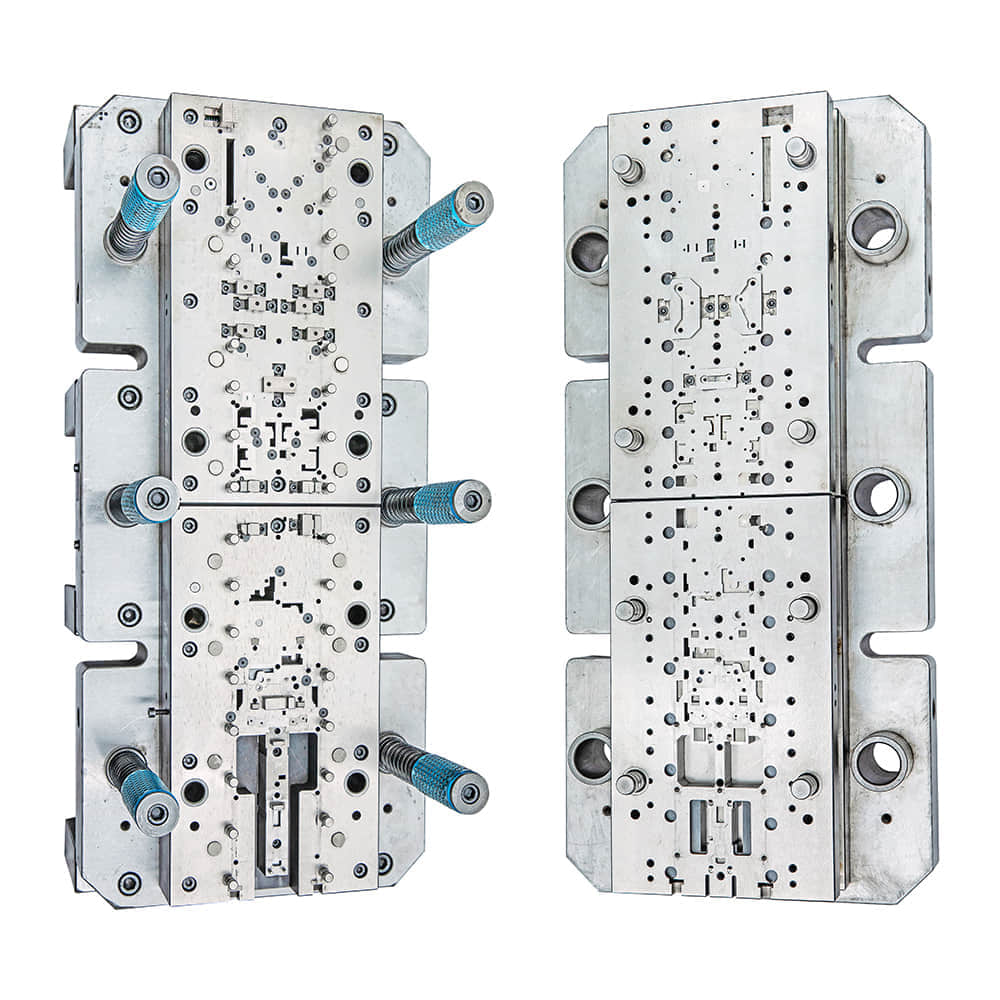

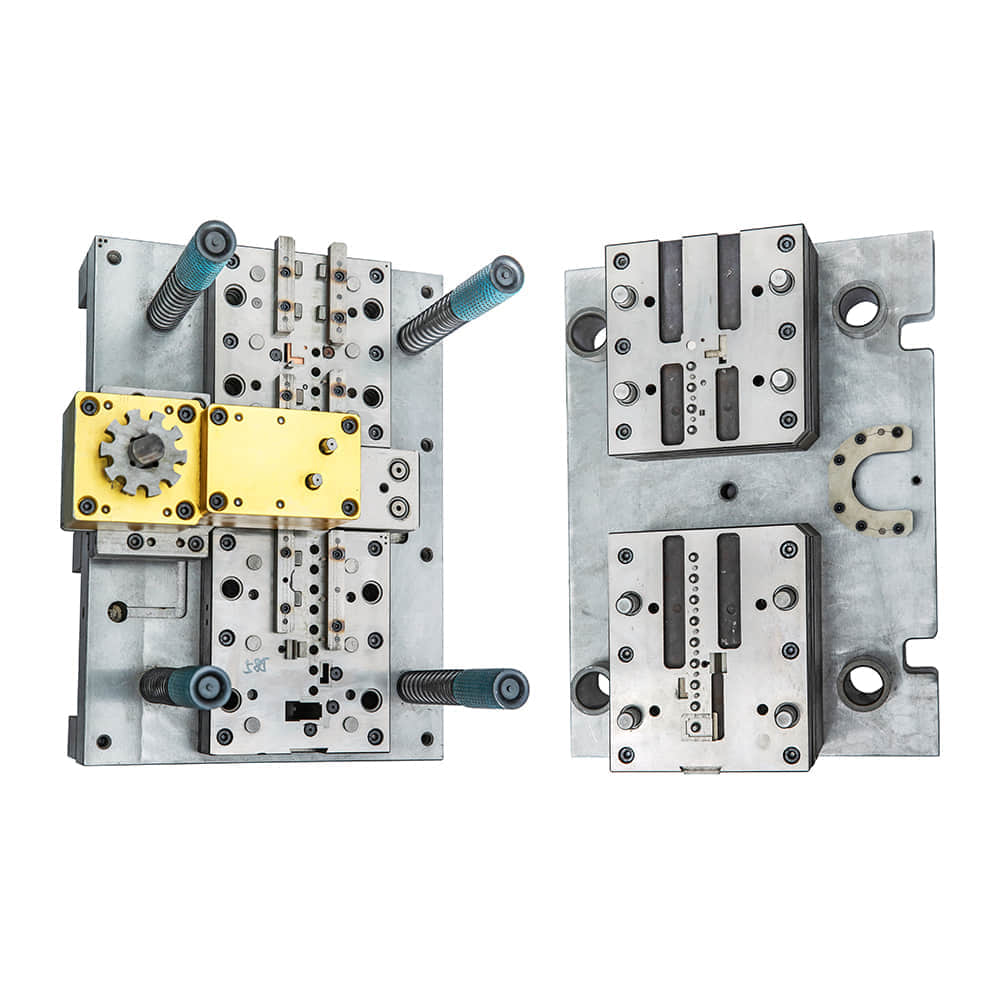

Metal stamping dies, often referred to as tooling dies, are specialized tools used to shape, cut, and manipulate sheet metal into specific forms. These forms can range from intricate designs in jewelry to intricate components in aerospace engineering. OEM (Original Equipment Manufacturer) manufacturers in the metal stamping die industry play a pivotal role in the creation of these essential tools. They collaborate with various industries to design, engineer, and manufacture custom-made stamping dies that align with the unique requirements of each client. Precision Engineering and Customization The hallmark of a reputable Metal Stamping Die OEM Manufacturer lies in their precision engineering capabilities. Each stamping die is meticulously designed using advanced computer-aided design (CAD) software, which allows for intricate details to be incorporated into the die’s design. These manufacturers possess the expertise to consider factors such as material properties, dimensional tolerances, and production volume, ensuring that the resulting stamping dies meet exact specifications and deliver consistent results throughout their lifespan. Customization is another key aspect that sets Metal Stamping Die OEM Manufacturers apart. Industries rarely have a one-size-fits-all approach to their products, and stamping dies must align with the specific requirements of each application. OEM manufacturers work closely with their clients to understand their needs, offering tailor-made solutions that optimize the manufacturing process and enhance efficiency. Technological Advancements and Innovation The landscape of metal stamping die manufacturing is continually evolving, thanks to technological advancements and innovation. Modern Metal Stamping Die OEM Manufacturers stay at the forefront of these changes by embracing new techniques, materials, and technologies. Computer numerical control (CNC) machining, additive manufacturing, and advanced heat treatment methods are just a few examples of how these manufacturers enhance the quality and longevity of their stamping dies. Furthermore, simulation tools are now integral to the design and validation process. Through simulations, manufacturers can predict how a stamping die will behave under different conditions, enabling them to make informed design decisions that result in optimal performance and longevity. This level of technological integration ensures that clients receive stamping dies that are not only precise but also built to withstand the rigors of high-volume production. Driving Industrial Success Metal Stamping Die OEM Manufacturers are unsung heroes in the manufacturing world. Their precision engineering, customization expertise, and commitment to innovation are pivotal in driving industrial success. Without their contributions, industries would struggle to produce the high-quality, intricately designed components that have become ubiquitous in our daily lives. In conclusion, the world of Metal Stamping Die OEM Manufacturing is a testament to the marriage of precision craftsmanship and cutting-edge technology. These manufacturers play an indispensable role in various industries by providing customized solutions that empower mass production without compromising on quality. As technology continues to advance, we can only anticipate that Metal Stamping Die OEM Manufacturers will continue to redefine what’s achievable in the realm of industrial manufacturing.