Metal stamping is a crucial process in the manufacturing industry, serving as the backbone for producing various metal components used in automobiles, electronics, appliances, and more. Behind the scenes of this intricate process lies the unsung hero, the Metal Stamping Die OEM Manufacturer. In this article, we will delve into the world of metal stamping dies, exploring their significance, the challenges faced, and the excellence that OEM manufacturers bring to this critical industry.

The Backbone of Metal Stamping

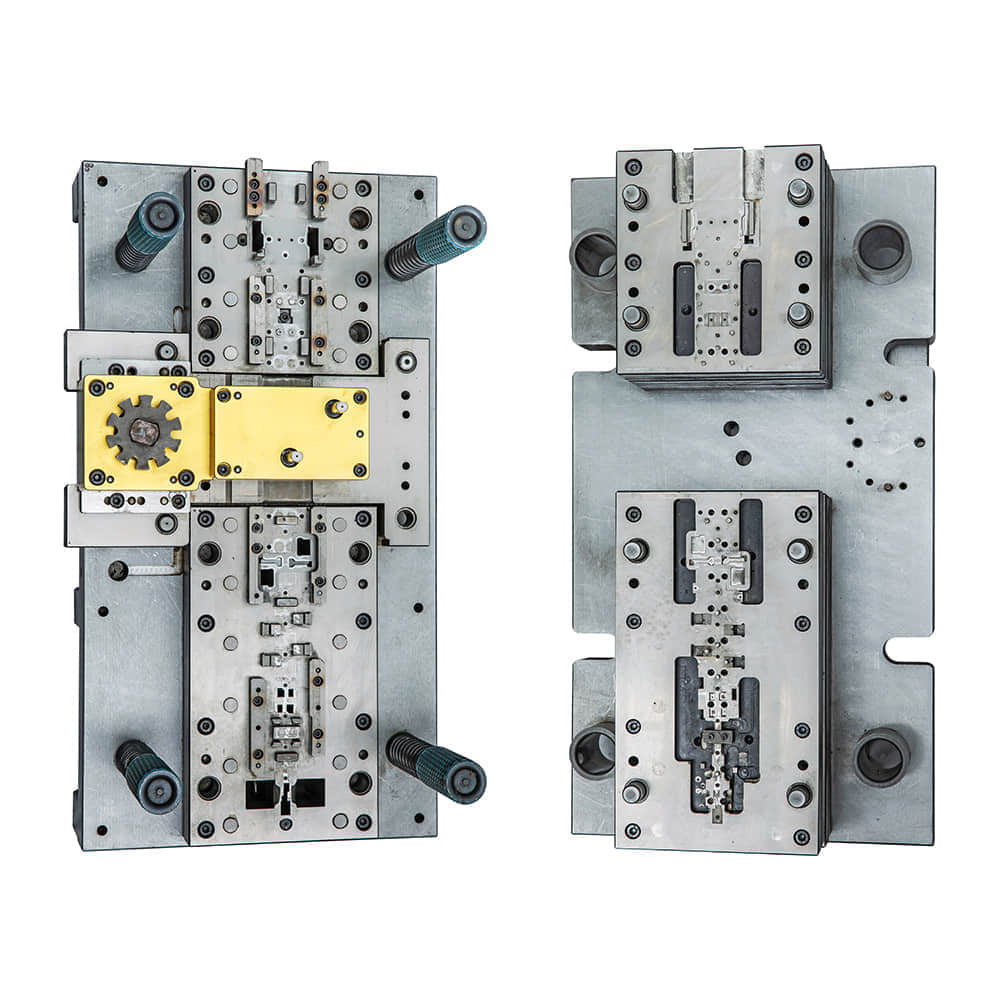

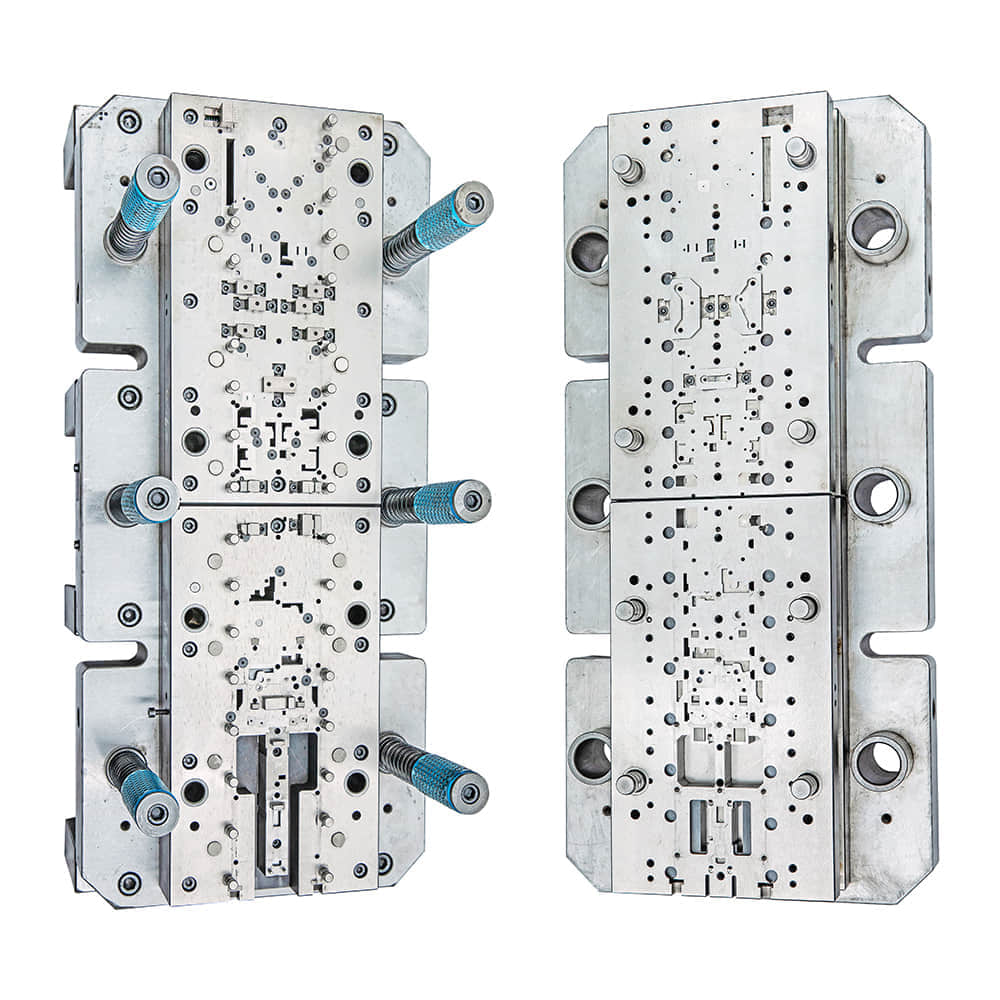

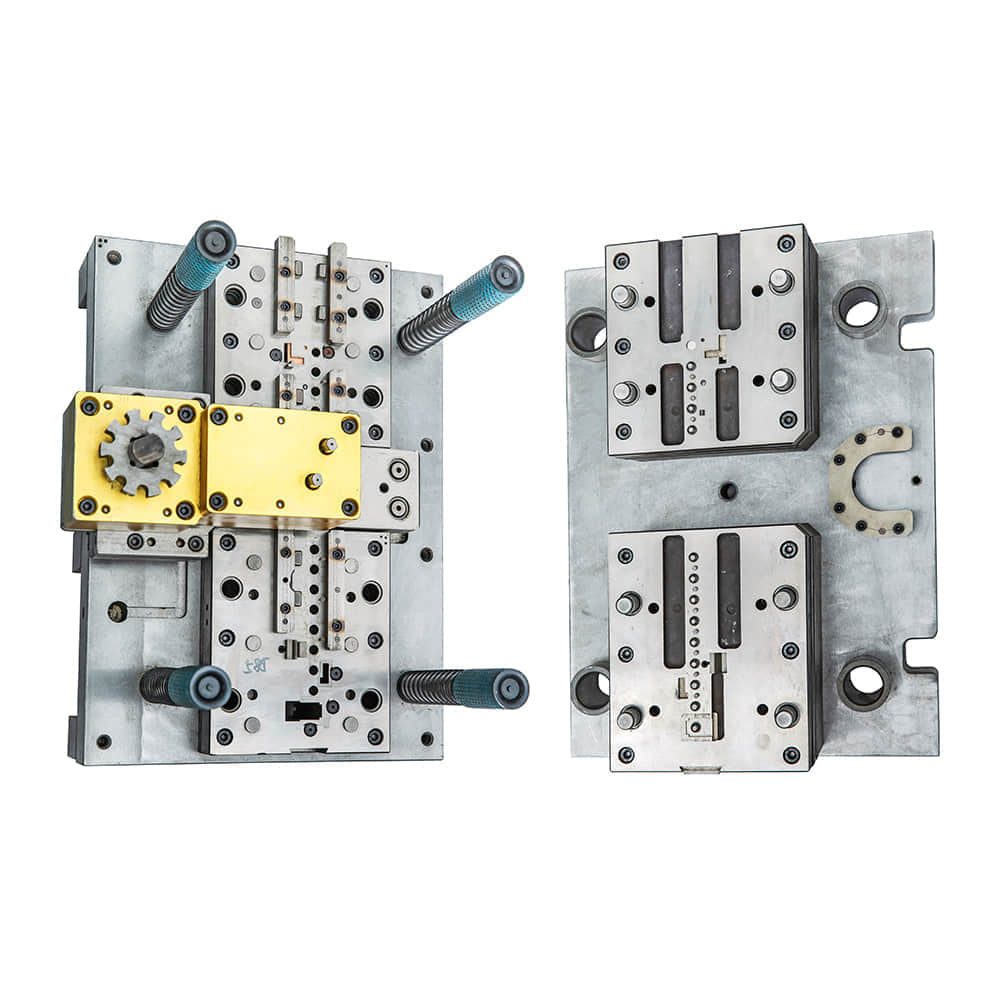

Metal stamping dies are specialized tools that shape and cut metal sheets into precise forms, catering to the exact requirements of diverse industries. These dies are the heart of metal stamping operations, responsible for creating intricate shapes with high precision and repeatability. Without the expertise of Metal Stamping Die OEM Manufacturers, many industries would struggle to meet their production needs. Precision Engineering Precision is paramount in the world of metal stamping. OEM manufacturers invest heavily in cutting-edge technology and employ skilled engineers to design and produce stamping dies that meet the tightest tolerances. The meticulous attention to detail ensures that each stamped part is consistent in quality and meets the required specifications. This precision is vital in industries like aerospace and medical, where safety and reliability are non-negotiable. Customization to Perfection Every industry has its unique demands when it comes to metal components. OEM manufacturers of metal stamping dies understand this and offer customized solutions. They work closely with their clients to design dies that perfectly suit their specific needs. Whether it’s creating a die for a one-of-a-kind prototype or mass-producing components for a major automotive manufacturer, Metal Stamping Die OEM Manufacturers adapt to the challenge with finesse. Innovation in Material Selection The choice of materials for stamping dies is critical to their longevity and performance. OEM manufacturers continually explore advanced materials and coatings to enhance die life and reduce maintenance costs. This commitment to innovation not only benefits the manufacturer but also trickles down to the end-users through improved product quality and cost-efficiency. Challenges Faced by OEM Manufacturers While Metal Stamping Die OEM Manufacturers excel in their craft, they face several challenges in delivering excellence: High Competition: The industry is fiercely competitive, pushing manufacturers to continuously innovate and improve. Technological Advancements: Keeping up with the latest technology is essential to remain competitive, but it requires significant investments. Quality Control: Maintaining strict quality control standards is paramount. Any deviation can result in costly production errors. Global Supply Chains: Dealing with global supply chains can introduce logistical challenges, especially during times of disruption. Environmental Responsibility In an era of increasing environmental awareness, OEM manufacturers of metal stamping dies are also focusing on sustainability. They are adopting eco-friendly practices, using recyclable materials, and minimizing waste to reduce their carbon footprint. This commitment to sustainability aligns with the broader industry trend towards responsible manufacturing. Conclusion Metal Stamping Die OEM Manufacturers are the unsung heroes of the metal stamping industry. Their commitment to precision engineering, customization, innovation, and environmental responsibility ensures the seamless production of vital components across various industries. As technology advances and industries evolve, these manufacturers will continue to adapt, playing a crucial role in shaping the future of metal stamping. Their dedication to excellence ensures that metal stamping remains a cornerstone of modern manufacturing.