Metal stamping is a fundamental process in the manufacturing industry, producing a wide range of components used in everything from automobiles to consumer electronics. At the heart of this process are metal stamping die manufacturers, the unsung heroes behind the scenes, whose precision and expertise ensure that the products we rely on daily meet the highest standards. In this article, we will delve into the world of metal stamping die manufacturers, exploring their role, the technologies they employ, and their contributions to various industries.

The Role of Metal Stamping Die Manufacturers

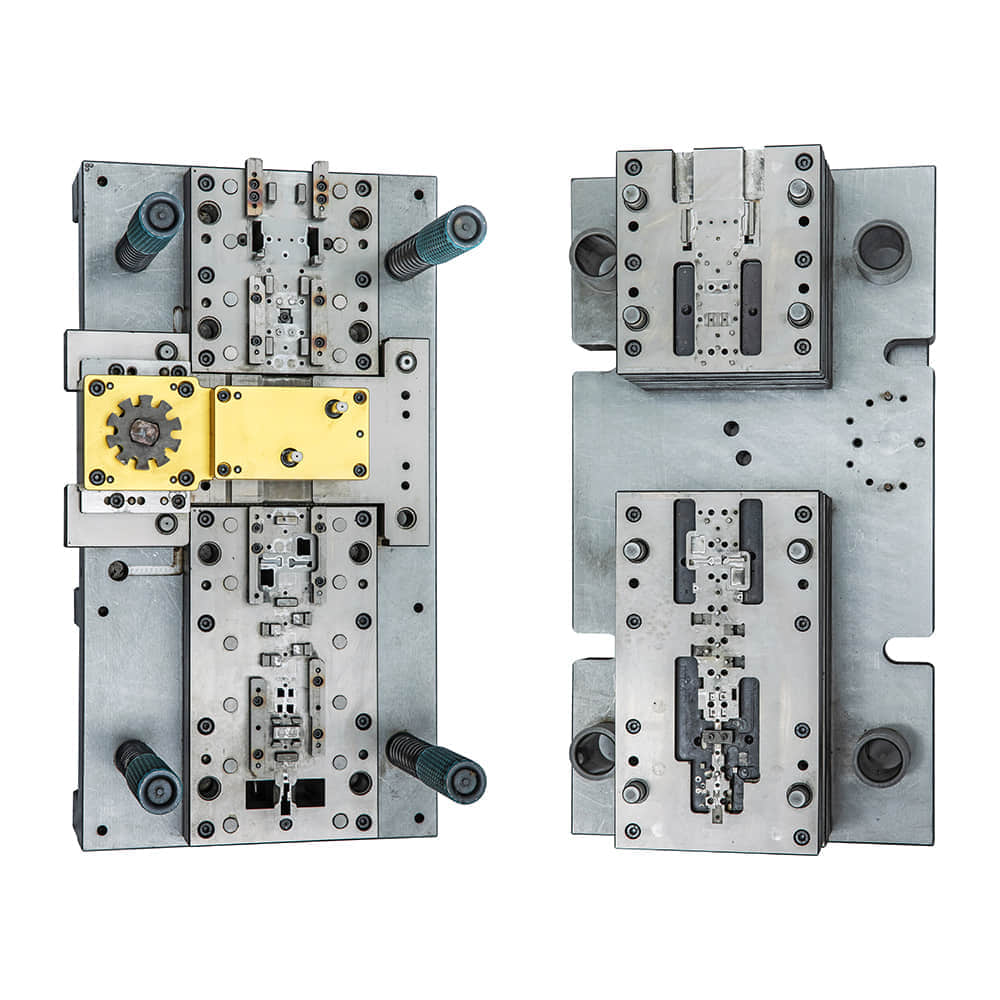

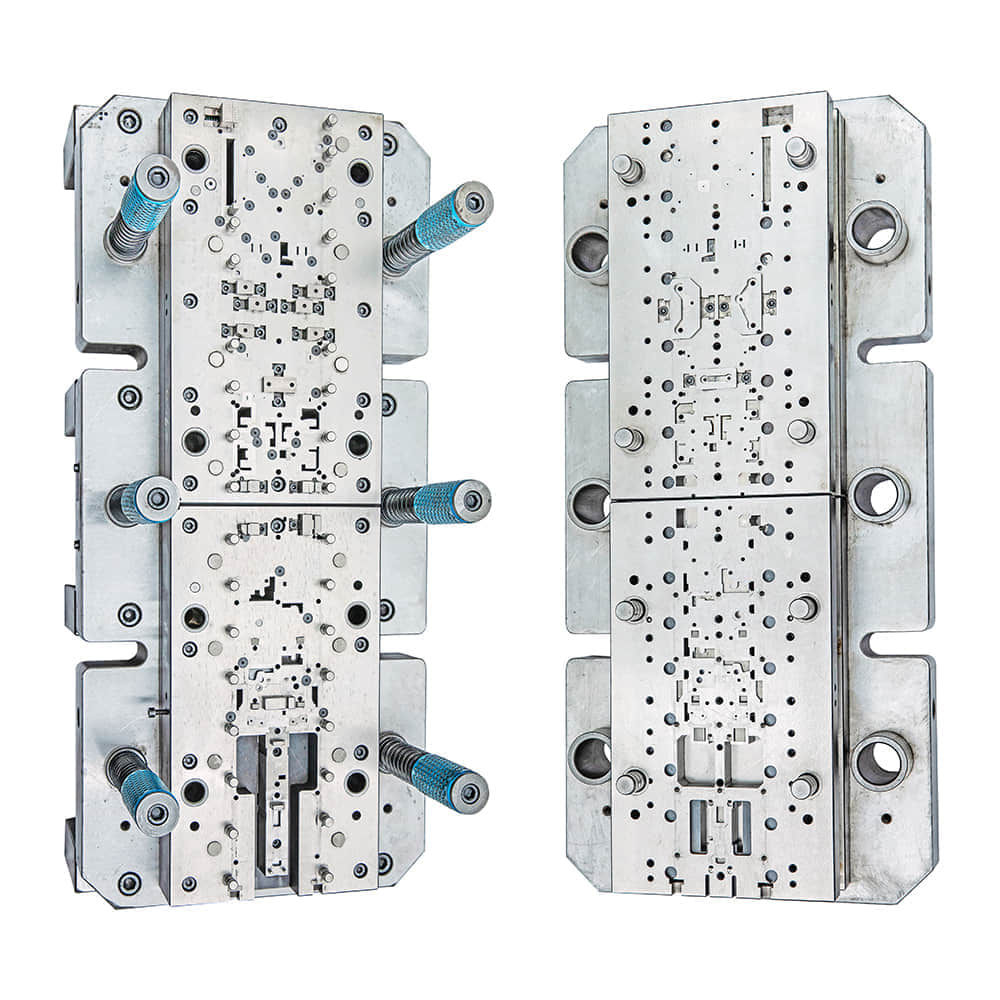

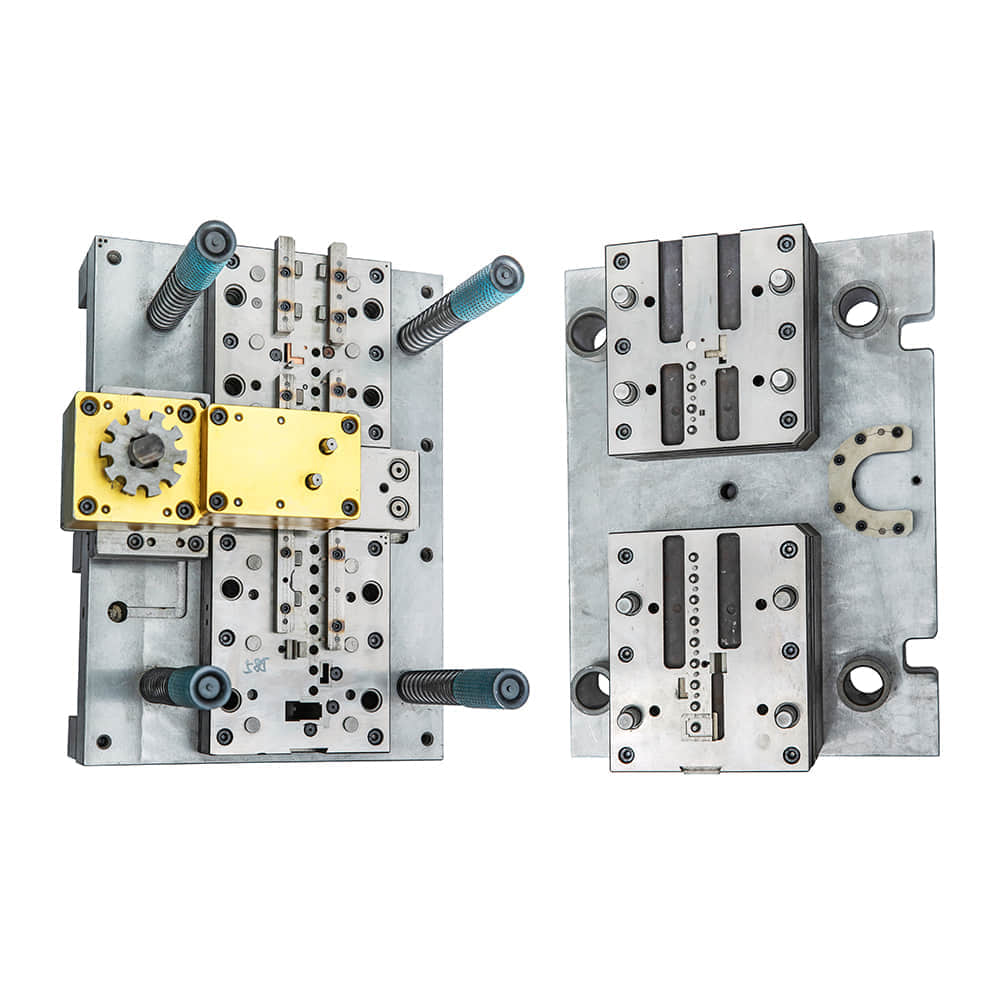

Metal stamping die manufacturers play a pivotal role in the production of metal components. Their primary responsibility is to design and create the dies used in the stamping process. These dies are essentially templates or molds that shape raw metal into specific forms. The precision and quality of these dies are paramount, as they directly impact the quality and consistency of the stamped parts. Innovative Technologies at Work Modern metal stamping die manufacturers utilize cutting-edge technologies to design and produce high-precision dies. Computer-Aided Design (CAD) software enables engineers to create intricate die designs with meticulous attention to detail. These designs can be simulated and optimized to ensure the die will produce flawless parts. Once the design phase is complete, Computer Numerical Control (CNC) machines come into play. These machines use the CAD data to precisely cut and shape the die components. CNC machining ensures that the tolerances are incredibly tight, leading to accurate and consistent part production. Materials Matter The choice of materials for stamping dies is critical. Dies must be able to withstand immense pressures and high-speed stamping processes. Common materials used include tool steel, carbide, and various specialty alloys. Die manufacturers carefully select materials based on the specific requirements of the project to ensure durability and longevity. Customization for Diverse Industries One of the key strengths of metal stamping die manufacturers is their ability to customize dies for various industries. Whether it’s the automotive sector, aerospace, electronics, or even medical devices, these manufacturers adapt their designs and materials to meet the unique demands of each industry. This versatility enables manufacturers in these sectors to produce high-quality components efficiently. Quality Control Quality control is a cornerstone of metal stamping die manufacturing. Each die undergoes rigorous testing to ensure it meets the highest standards. This includes dimensional checks, hardness testing, and often a trial run with the stamping press to validate its performance. These stringent quality control measures guarantee that the dies are fit for production. Meeting Environmental Standards In today’s world, environmental responsibility is a top priority. Metal stamping die manufacturers are no exception. Many have adopted eco-friendly practices, such as using sustainable materials and implementing energy-efficient production processes. This not only reduces the environmental footprint but also aligns with the sustainability goals of their clients. Continuous Innovation The field of metal stamping die manufacturing is not stagnant. Continuous innovation is at its core. Manufacturers are always seeking ways to improve efficiency, reduce waste, and enhance the quality of their dies. This commitment to innovation ensures that the industry remains competitive and able to meet the ever-evolving needs of diverse markets. Conclusion Metal stamping die manufacturers are the unsung heroes of the manufacturing world. Their precision, innovation, and dedication to quality make them indispensable to industries worldwide. Whether you’re driving a car, using a smartphone, or relying on medical equipment, chances are you’re benefiting from the expertise of these manufacturers. As technology advances and industries grow, the role of metal stamping die manufacturers will only become more crucial in shaping the products that shape our world.