Metal stamping is a fundamental process in the manufacturing industry, serving as the backbone for producing countless products we use in our daily lives. From automotive parts to consumer electronics, metal stamping plays a pivotal role in shaping metal sheets into various forms. At the heart of this process are the unsung heroes, metal stamping die manufacturers, who craft the tools that make precision and efficiency possible.

The Craftsmanship Behind Metal Stamping Dies

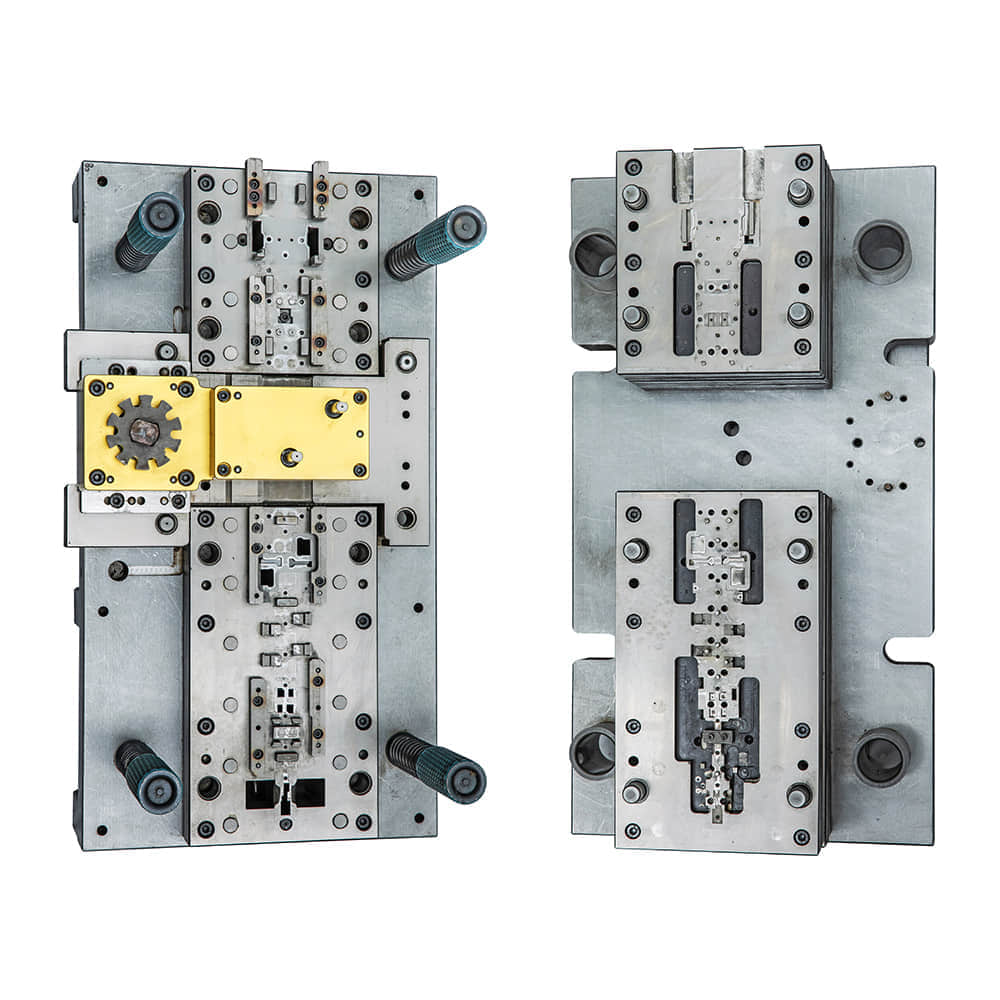

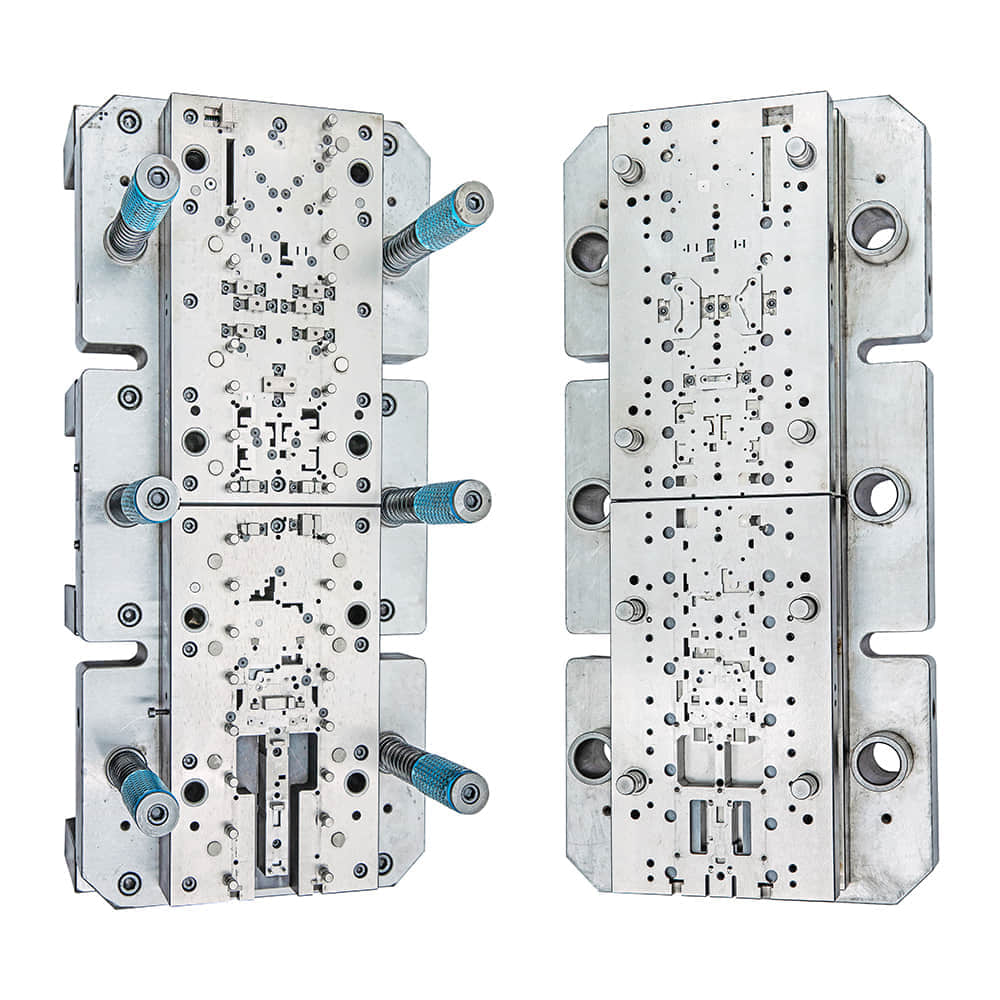

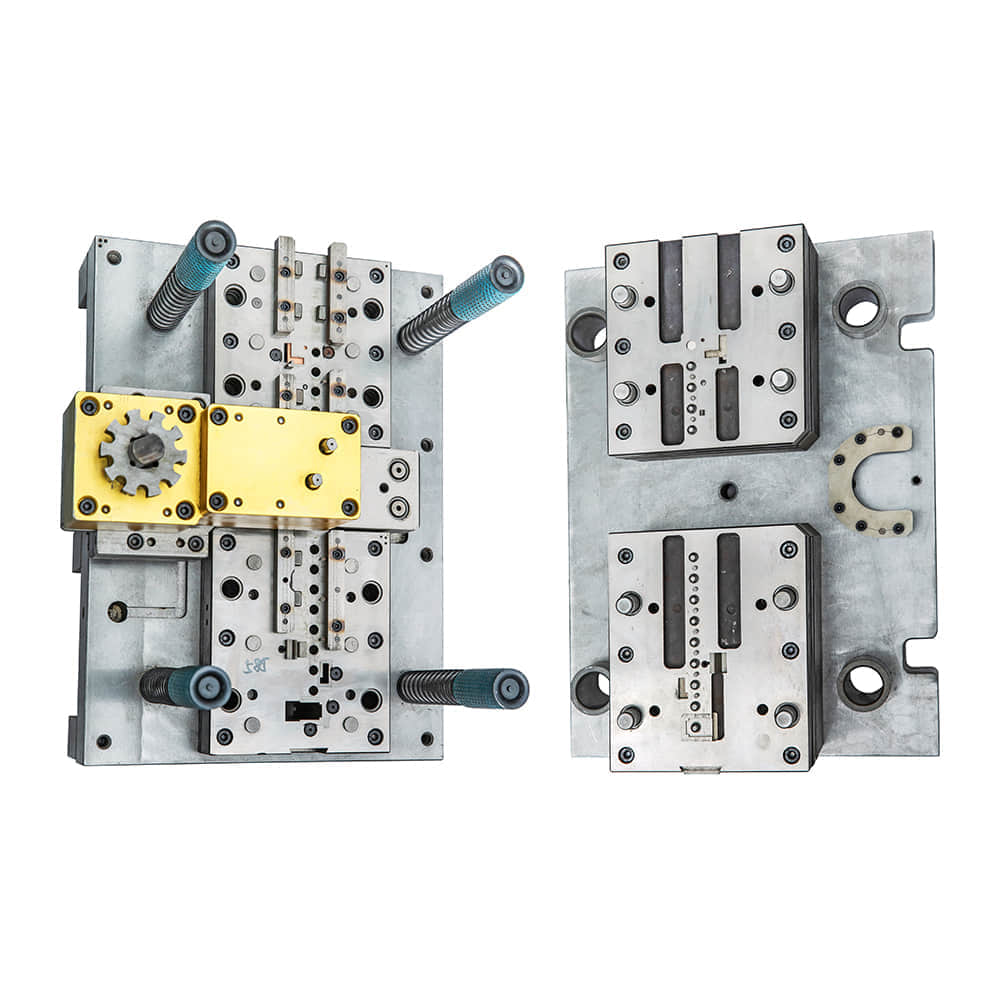

Metal stamping dies, also known as tooling or molds, are precision-engineered devices used to cut, shape, and form metal sheets into specific shapes and sizes. These dies are the cornerstone of metal stamping operations, determining the quality, accuracy, and consistency of the final products. To appreciate the craftsmanship behind metal stamping dies, one must understand the intricate process involved in their creation. It all begins with skilled engineers and toolmakers who meticulously design the dies. Their expertise is crucial in ensuring that the die will meet the exact specifications required for the intended stamped parts. Materials Matter High-quality materials are paramount in die manufacturing. Most dies are made from tool steel, known for its exceptional hardness and wear resistance. The choice of material depends on factors such as the type of metal being stamped, the complexity of the part, and the expected production volume. Die manufacturers must carefully select the appropriate steel grade and meticulously machine it to create the die’s core components. These core components, often referred to as inserts or cavities, are where the magic happens. They are intricately shaped to produce the desired stamped parts with impeccable precision. Precision Machining The machining process is where the true craftsmanship of die manufacturing shines. Advanced CNC (Computer Numerical Control) machines are used to precisely shape the core components of the die. These machines operate with micron-level precision, ensuring that even the tiniest details of the die are accurate. Skilled machinists oversee this process, constantly monitoring for any deviations and making adjustments as needed. They use a range of cutting tools, including milling cutters, grinding wheels, and EDM (Electrical Discharge Machining) electrodes, to achieve the required geometries and surface finishes. Testing and Quality Assurance Once the core components are machined, they undergo rigorous testing and quality assurance procedures. This involves measuring the dimensions of critical features, checking for any defects, and ensuring that the die meets the specified tolerances. Dies are also subjected to trial stamping runs to verify their functionality and consistency. Any issues are addressed promptly to ensure that the die will perform flawlessly during production. Customization and Adaptability One of the remarkable aspects of metal stamping die manufacturers is their ability to customize and adapt dies to meet diverse industry needs. Whether it’s a simple blanking die or a complex progressive die for manufacturing intricate parts, die manufacturers can tailor their designs to suit specific requirements. Innovation in Die Manufacturing The field of metal stamping die manufacturing is not stagnant. Continuous innovation drives the development of new materials, techniques, and technologies. Manufacturers are exploring ways to improve die longevity, reduce production costs, and enhance overall efficiency. Automation and computer-aided design have also made die manufacturing more efficient and precise. 3D modeling and simulation allow manufacturers to visualize and optimize die designs before they are physically created, reducing the margin of error. Conclusion Metal stamping die manufacturers are the unsung heroes of the manufacturing world. Their craftsmanship and dedication to precision are the driving forces behind the production of countless everyday products. As technology advances and industry demands evolve, these manufacturers continue to push the boundaries of what is possible, ensuring that metal stamping remains a vital and innovative industry.