In the realm of industrial manufacturing, metal stamping plays a pivotal role in shaping and transforming raw materials into finely crafted components. At the heart of this process lies the ingenuity of metal stamping die manufacturers, the unsung heroes of precision engineering. In this article, we will explore the world of metal stamping die manufacturers, their essential contributions to various industries, and the intricate artistry behind their craft.

I. The Essence of Metal Stamping Die Manufacturers

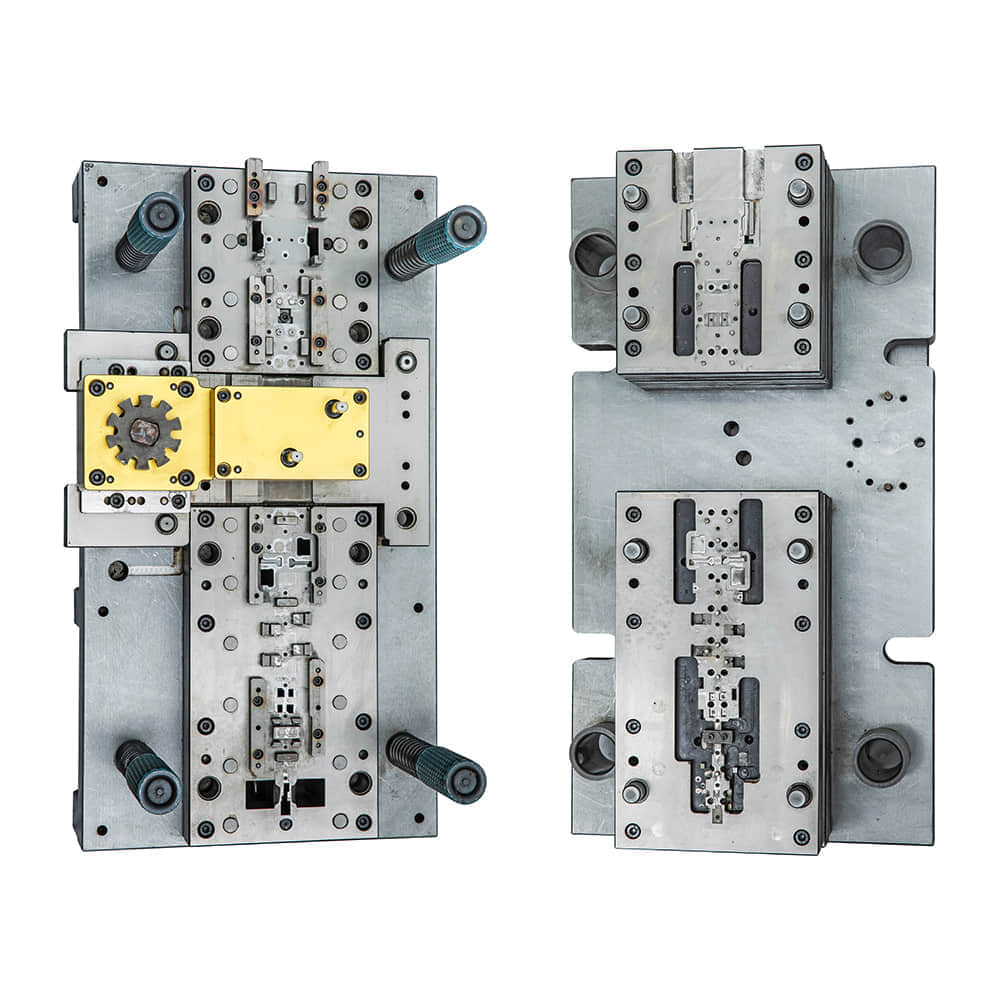

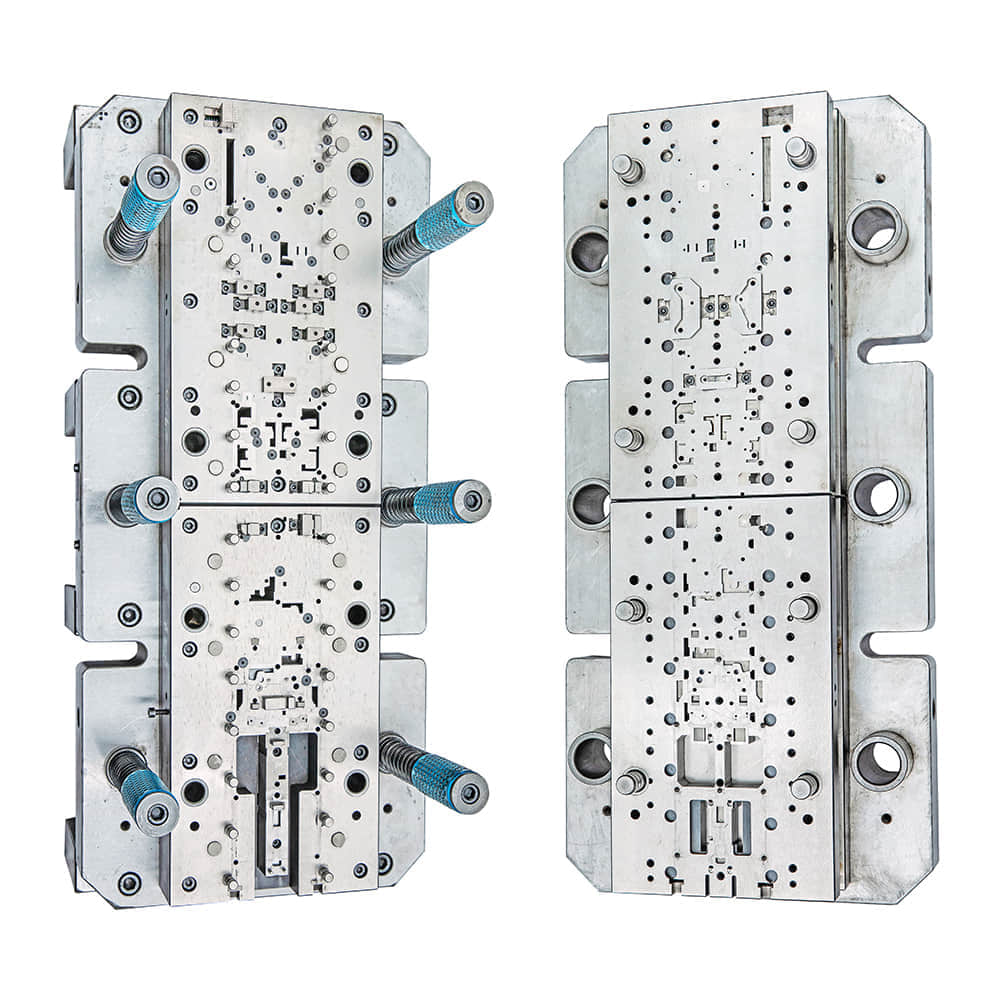

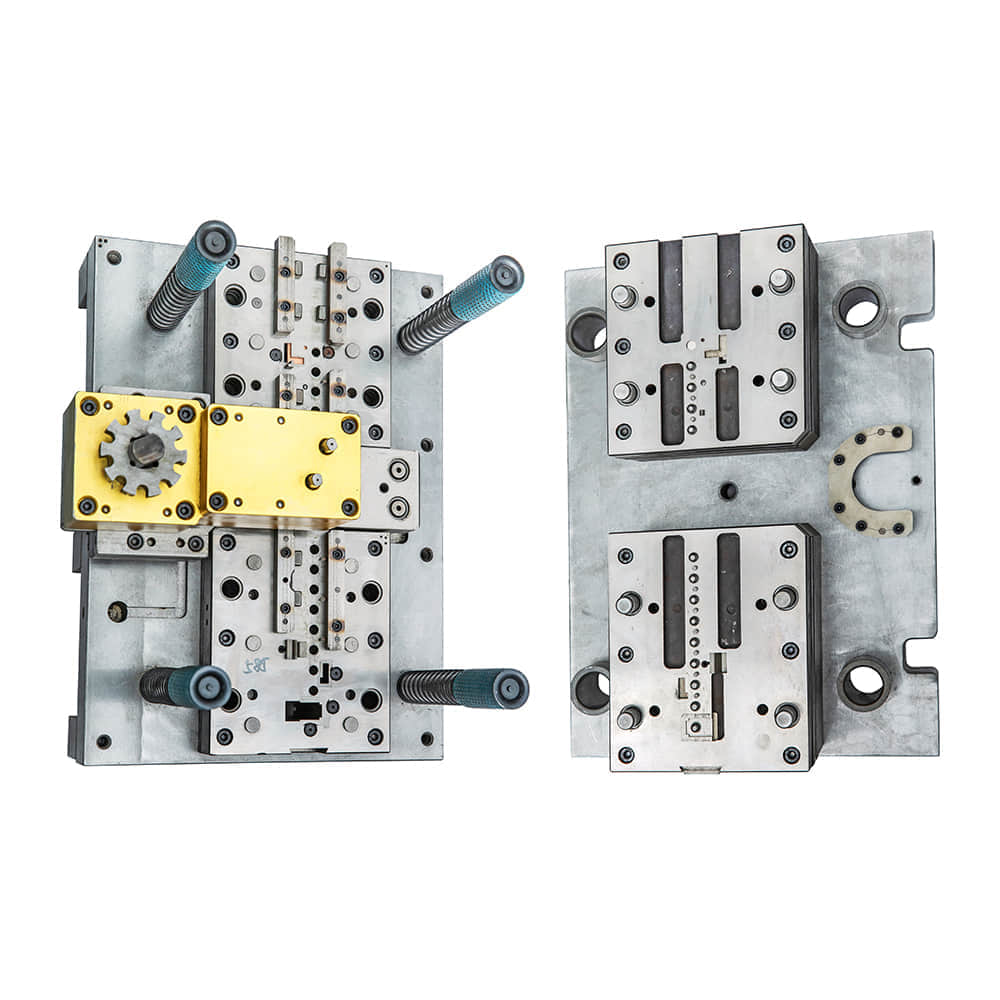

Metal stamping die manufacturers are the architects of precision tooling. They design and fabricate dies, molds, and tooling systems used in the metal stamping process. These experts are adept in working with various metals, including steel, aluminum, and brass, and their skills are indispensable across multiple industries, from automotive and aerospace to electronics and consumer goods. II. The Craftsmanship of Precision Tooling The core of metal stamping lies in precision tooling. Metal stamping die manufacturers are tasked with creating intricate molds and dies that can withstand high pressures and temperatures while maintaining the tightest tolerances. Each component they produce must be flawless, as even a minuscule imperfection can lead to costly defects in the final product. III. Materials and Technologies To achieve such precision, metal stamping die manufacturers leverage cutting-edge technologies and materials. Computer-Aided Design (CAD) software allows them to create intricate die designs with unparalleled accuracy. High-strength steel and carbide are often the materials of choice for die construction due to their durability and wear resistance. IV. Customization for Diverse Industries One of the hallmarks of metal stamping die manufacturers is their ability to customize tooling solutions to meet the specific needs of different industries. For example, dies used in the automotive sector must be capable of mass-producing parts with uniformity, while aerospace applications demand extreme precision and reliability. Metal stamping die manufacturers adapt to these requirements seamlessly. V. Innovation and Efficiency Continuous improvement and innovation are vital in the world of metal stamping die manufacturing. As industries evolve, manufacturers must stay at the forefront of technological advancements. This includes adopting automation and robotics to enhance efficiency, reduce production time, and minimize waste. Innovation in die coatings, lubrication systems, and cooling techniques further enhances the quality of the stamped products. VI. Quality Assurance Quality control is a non-negotiable aspect of metal stamping die manufacturing. Rigorous inspection processes, including dimensional checks and material testing, are conducted to ensure that each die meets the highest standards. This commitment to quality ensures the longevity and reliability of the tooling. VII. Environmental Responsibility In recent years, environmental responsibility has become a key focus for metal stamping die manufacturers. They are developing eco-friendly solutions, such as recyclable die components and sustainable production practices, to reduce their environmental footprint. This aligns with the broader global shift toward sustainable manufacturing. VIII. Conclusion Metal stamping die manufacturers are the unsung heroes of the industrial world, providing the precision tooling necessary for the creation of countless products. Their craftsmanship, innovation, and dedication to quality drive industries forward and enable the production of everything from automobiles to consumer electronics. As technology continues to advance and industries evolve, these manufacturers will remain at the forefront of precision engineering, shaping the future of manufacturing.