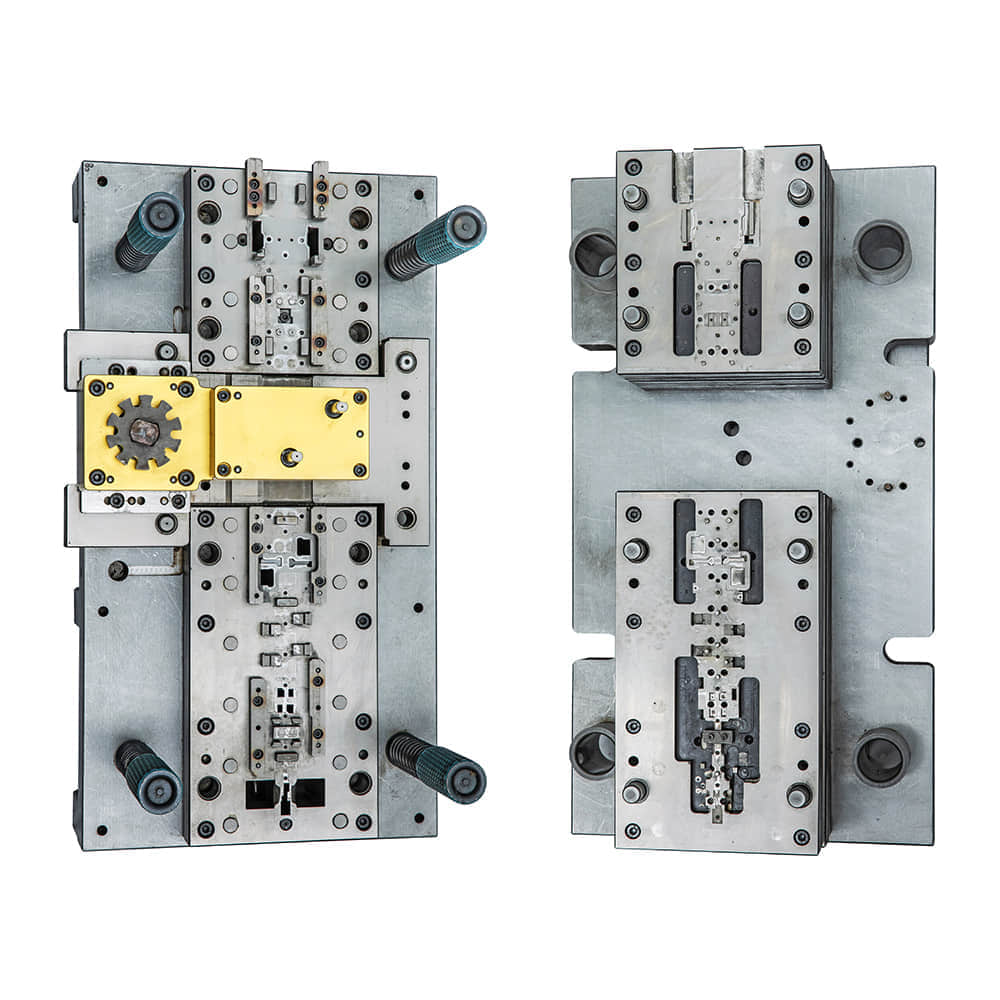

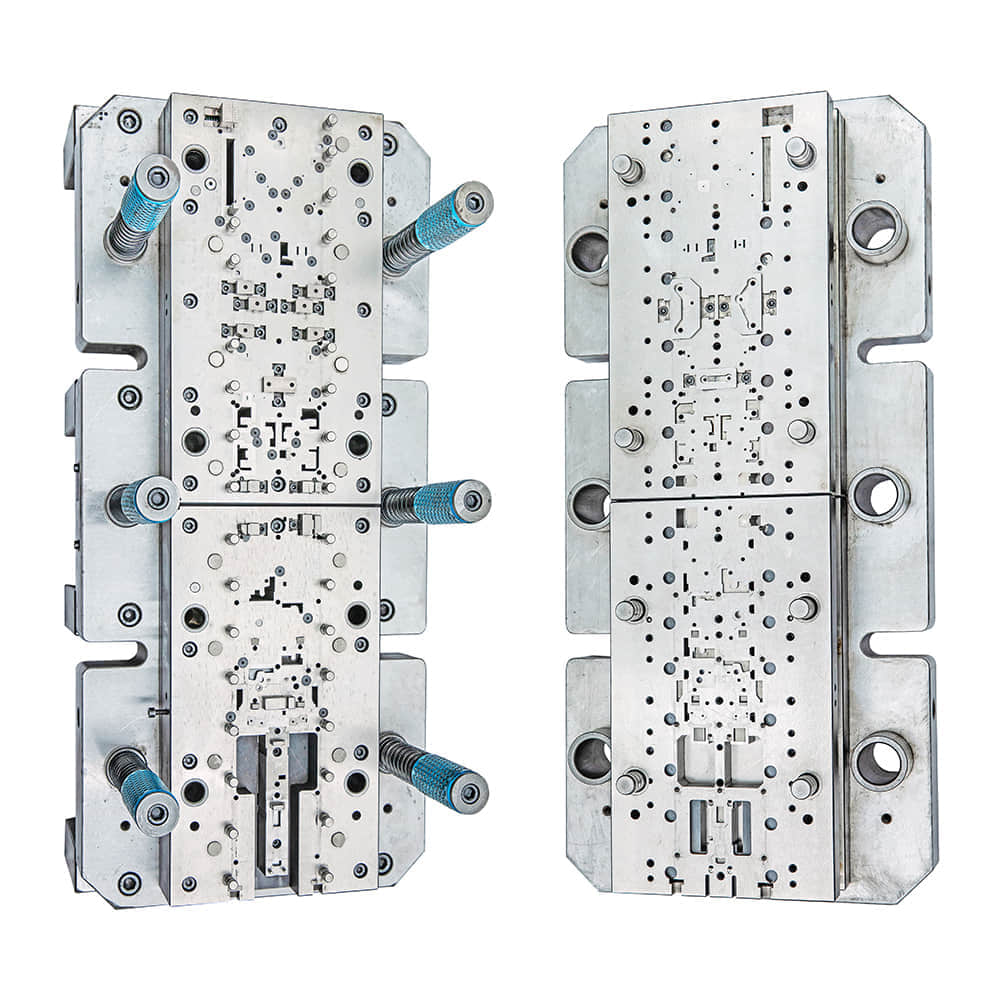

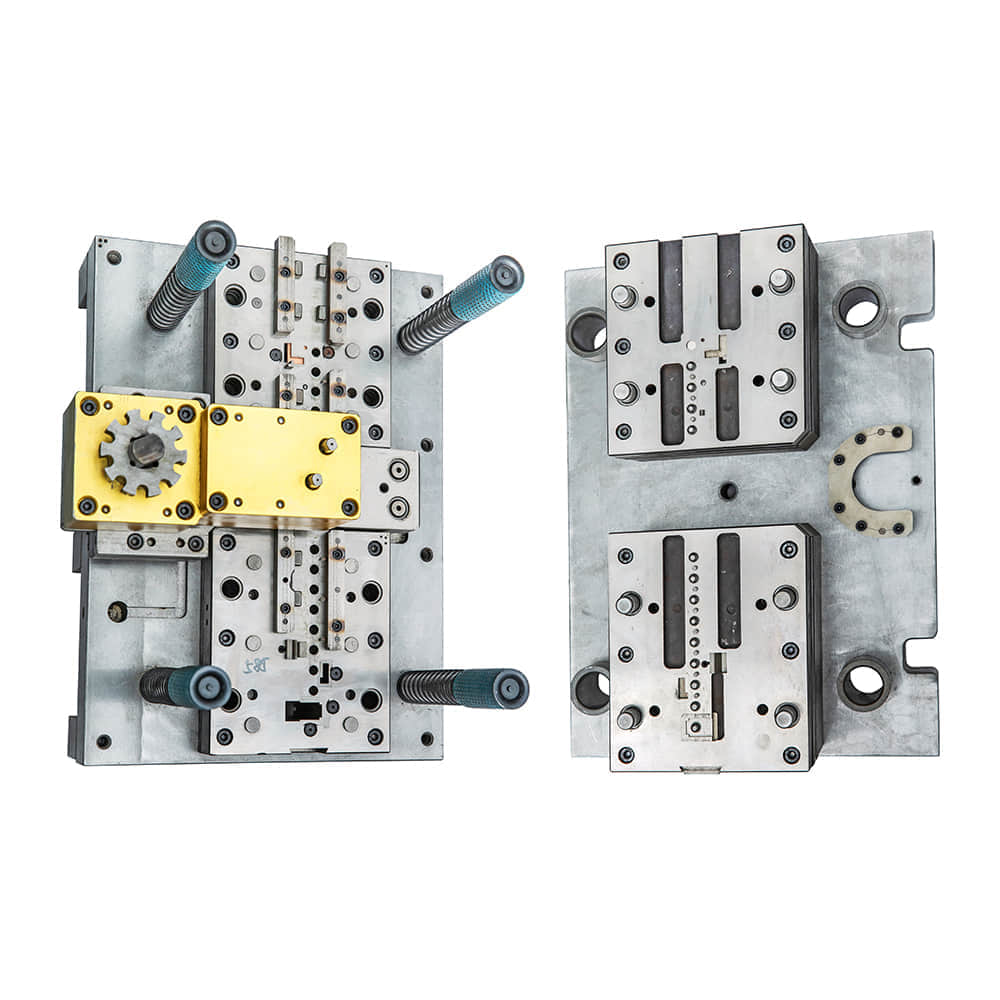

Metal stamping is a crucial process in the manufacturing industry, allowing for the mass production of intricate metal components used in various applications. At the heart of this process are metal stamping die manufacturers, who play a pivotal role in crafting the dies that shape raw metal into precise and functional parts.

Precision Engineering for Perfection

Metal stamping dies are specialized tools used to shape, cut, or mold metal sheets into desired forms. These dies come in various types, such as blanking dies, piercing dies, bending dies, and progressive dies, each serving a unique purpose in the stamping process. The precision required in die manufacturing is paramount, as even the slightest deviation can lead to defective parts or production delays. Manufacturers employ cutting-edge technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), to create intricate die designs with micron-level precision. These designs are then translated into physical dies using advanced machining techniques like CNC (computer numerical control) milling, electrical discharge machining (EDM), and wire EDM. The marriage of digital innovation with traditional craftsmanship ensures that the resulting dies can withstand the rigors of high-volume production while maintaining consistency and accuracy. Efficiency in Production Metal stamping die manufacturers not only prioritize precision but also focus on optimizing production efficiency. The design of the die itself, including the layout of punches, cavities, and ejector systems, impacts how efficiently the stamping process can be carried out. A well-designed die minimizes material waste, reduces production cycle times, and enhances overall productivity. Furthermore, some manufacturers specialize in progressive dies, which allow for a series of operations to be performed in a single pass of the metal strip. This approach eliminates the need for multiple setups and reduces the time required to produce a finished part. By streamlining the production process, manufacturers contribute to cost savings for their clients while maintaining the highest quality standards. Customization for Diverse Industries Metal stamping die manufacturers cater to a wide array of industries, from automotive and aerospace to electronics and consumer goods. Each industry has its unique requirements, and manufacturers must adapt their designs and processes accordingly. For instance, the automotive industry demands precision-engineered parts that contribute to the safety and performance of vehicles. Metal stamping die manufacturers for this sector must ensure that their dies create components with consistent dimensions and impeccable surface finishes. In the electronics industry, where miniaturization is a prevailing trend, manufacturers are challenged to produce tiny, intricate components with high precision. This requires not only advanced die-making techniques but also a deep understanding of the materials and their behavior during the stamping process. Innovation and Adaptation The field of metal stamping die manufacturing is not static. Manufacturers are continually innovating to keep up with evolving technologies and industry demands. This might involve adopting new materials for die construction that offer greater durability or developing novel techniques for enhancing the lifespan of dies under heavy usage. Moreover, environmental considerations are driving the adoption of sustainable practices in manufacturing. Some metal stamping die manufacturers are exploring ways to reduce waste generation, energy consumption, and the use of harmful chemicals in their processes. This commitment to sustainability benefits both the industry and the planet. Conclusion Metal stamping die manufacturers play a vital role in the modern manufacturing landscape by creating the essential tools that shape raw metal into precision-engineered components. Their dedication to precision, efficiency, customization, and innovation ensures that industries ranging from automotive to electronics can access the high-quality parts they need for their products. As technology continues to advance, we can expect metal stamping die manufacturing to reach even greater levels of sophistication, enabling the production of increasingly intricate and reliable metal components.