In the realm of industrial automation, reliability and longevity are paramount. This is where the Long Service Life Solenoid Valve plays a crucial role. Engineered for extended service periods without frequent replacement or maintenance, these solenoid valves are essential for industries where continuous operation and minimal downtime are critical. In this article, we will delve into the features, advantages, and applications of the Long Service Life Solenoid Valve, highlighting its importance in modern automation systems.

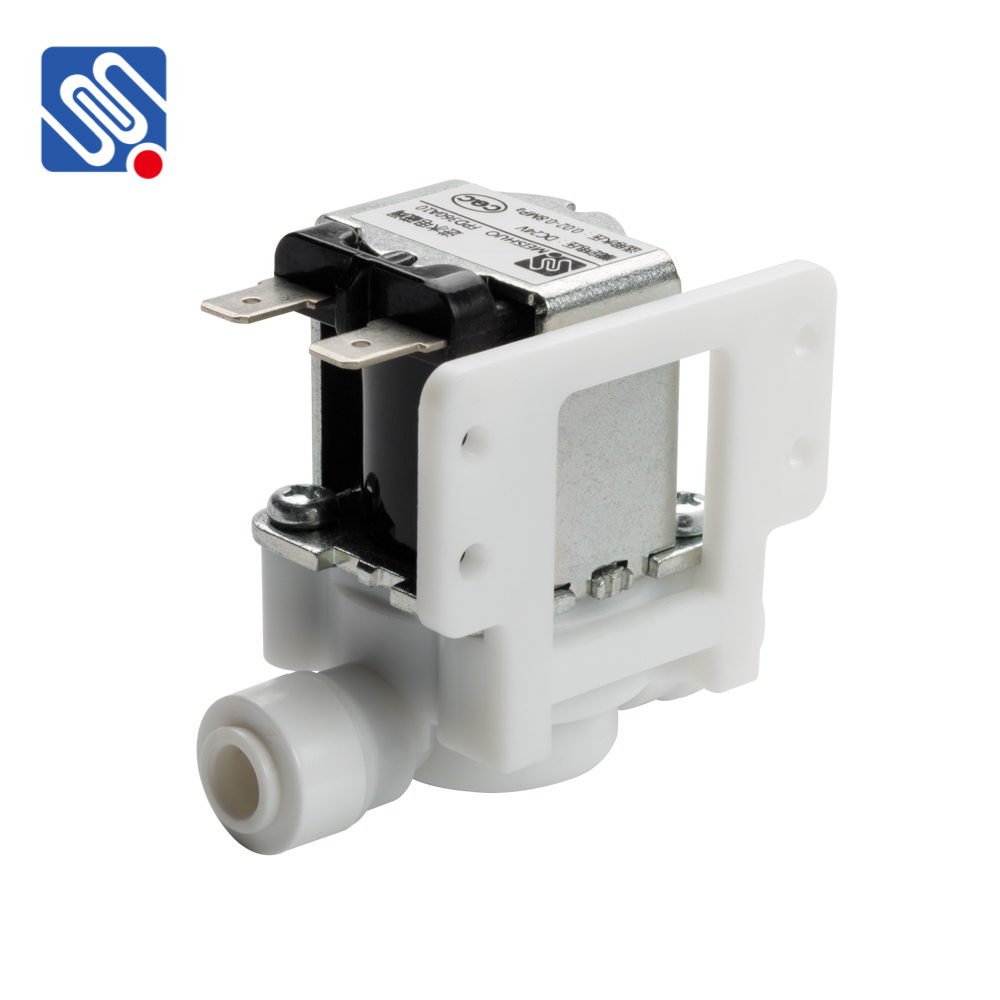

What is a Long Service Life Solenoid Valve? A solenoid valve is an electromechanically operated valve that controls the flow of liquids or gases in a system. It uses an electric current to generate a magnetic field that moves a plunger, either opening or closing the valve. While standard solenoid valves have their uses, Long Service Life Solenoid Valves are designed to offer enhanced durability and performance. These valves are specifically engineered to withstand extended use in harsh environments, reducing the need for frequent replacements and maintenance. The key difference between standard solenoid valves and their long-service counterparts lies in their design and the materials used. Long service life valves typically feature high-quality construction materials such as stainless steel, brass, or specialized alloys, which provide better resistance to wear, corrosion, and extreme temperatures.